Industrial Food Drying Machine Introduction

The industrial food dryer can quickly remove moisture from materials without affecting the original color, shape and nutrients of the food. The industrial hot air circulation drying furnace is equipped with a computer control system, which can realize automatic constant temperature control.

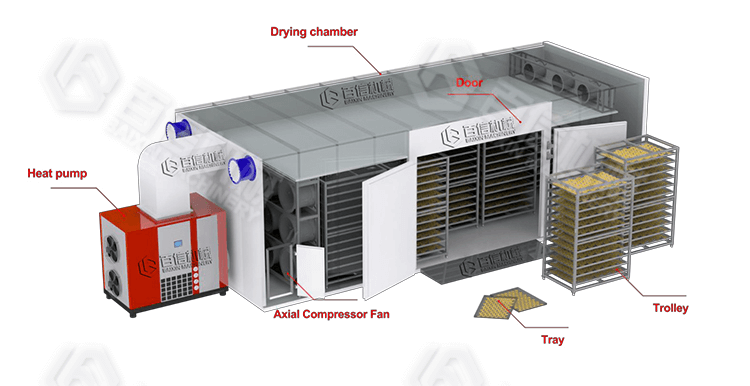

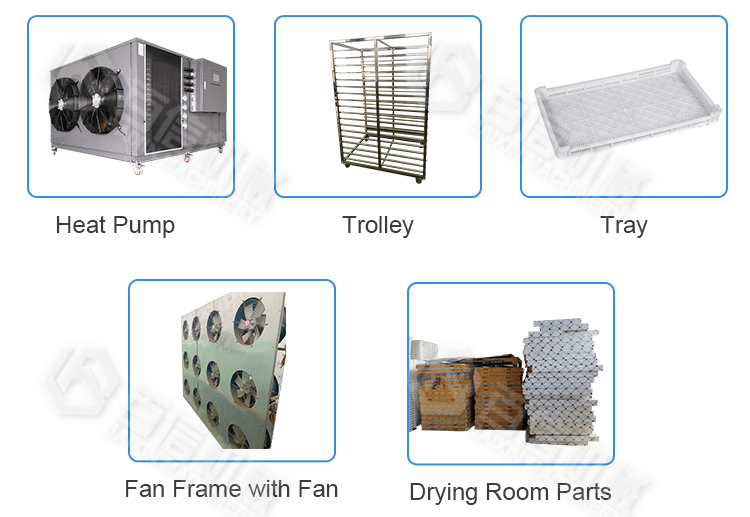

Different from the small hot air dryer, the large hot air dryer has more carts and trays to hold materials, which is suitable for large-scale material drying production. The drying temperature range of this heat pump dryer is 20-80℃, and the materials suitable for drying are very wide, such as grains, edible fungi, medicines, seafood, bacon, fruits and vegetables, tobacco leaves, seeds, spices, etc

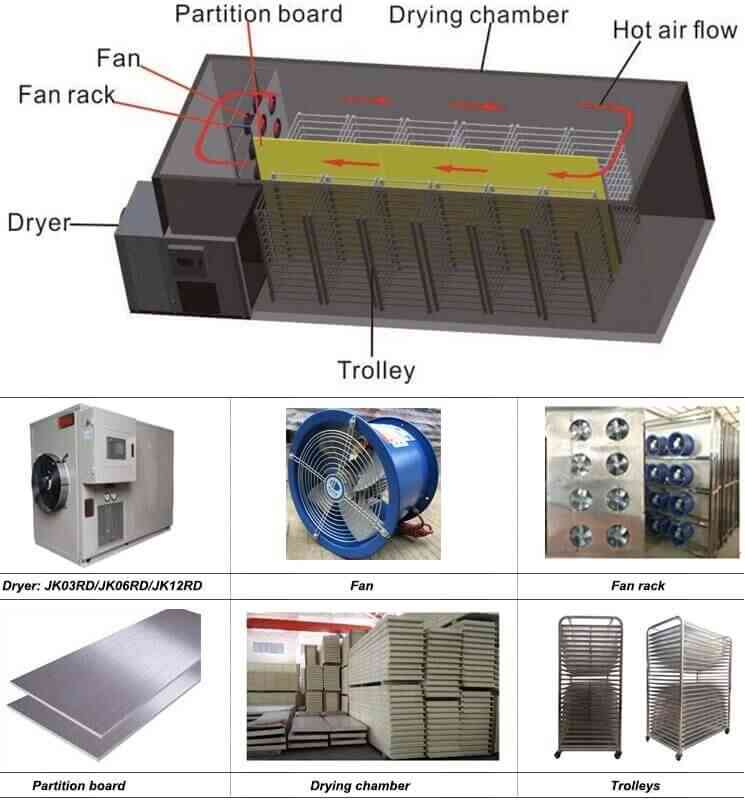

Spotlights of Large Hot Air Circulation Food Drying Oven

Reliable and safe operation due to forced ventilation effect, in which there is an adjustable wind board.

Air inlet is equipped with highly efficient air filter and the exhaust event is equipped with medium efficient air filter.

Drying tray made of stainless steel, easy moving, durable and convenient to clean.

Low noise, reliable and safe operation, temperature-controlled, easy installation and maintenance.

Baking timer per batch: 4-6 hours per batch according to different materials.

Wide application: a variety of materials can be dried like vegetables, fruits, herbs, mushroom and etc..

Characteristics of Hot Air Food Drying Machine

1. During the drying process, the material will not be deformed, discolored, or degraded, and dried thoroughly, with less nutrient loss and a long storage period. It can effectively protect the color, taste and active ingredients of the dried material more than any conventional drying equipment.

2. Energy saving: heat pump technology is adopted to absorb air heat while recovering waste heat, and airtight dehumidification + circulating drying method is adopted to save operating costs.

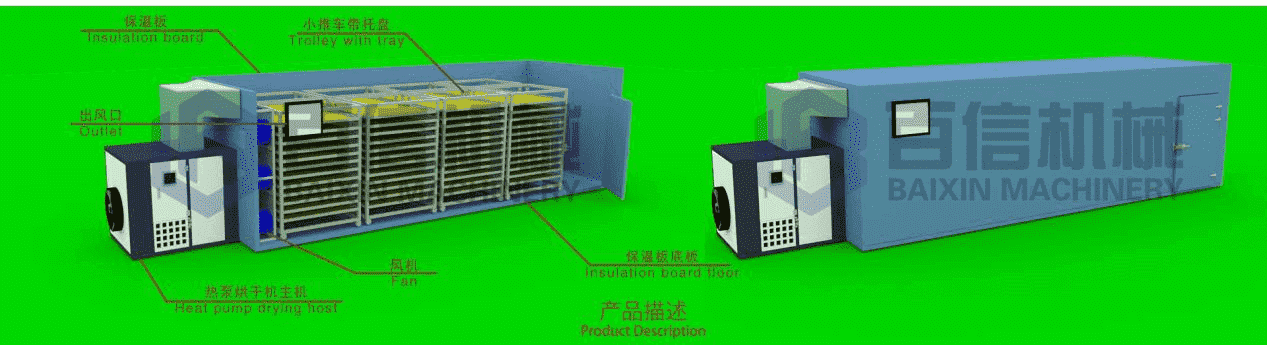

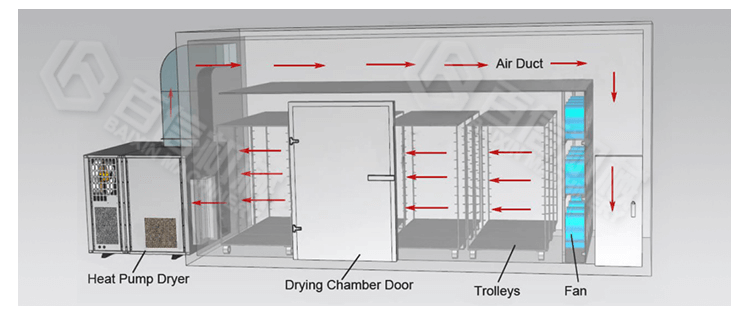

3. Easy to install and operate, just connect to the drying chamber through the air duct.

4. Uniform drying: The forced ventilation function is adopted. The drying room is equipped with partitions and fan motors to ensure the circulation of hot air and make the raw materials uniformly dry.

5. Efficient and environmentally friendly, it absorbs heat from the air to dry materials without any pollution discharge. Compared with traditional drying technology, it saves about 70% of operating costs.

Choose Suitable Tray of Hot Air Circulation Oven:

Choose Suitable Tray of Hot Air Circulation Oven:

The oven plate, also known as the oven tray, is an important part of the dryer. We have a variety of types of plates, according to different materials, choose a suitable drying method, in order to achieve efficient drying and dewatering effect. Roughly divided into three categories:

1. Punching plate: suitable for granular materials

2. Manual multi-sided board: good air permeability, suitable for strip, sheet materials and loose materials

3. Non-porous plate: moderate air permeability, suitable for powder and liquid materials

The heat pump can be used in many application,like agriculture,industry,seafood,grain,herbs,construction,paper products,seasoning,mineral industry,etc

Dry vegetables like Radish, lettuce, pumpkin, carrots, spinach, cassava,etc

Dry fruits like Apple, lemon, mango slices, dried longan, dried longan,etc

Dry meat: Sausage, beef, duck, ham,etc

Others it can dry noodle/ wooden /stick incense/herbs /floers ect.

Your product is not listed above? We are ready to meet any new challenge! Contact us for free product testing!

Application of Seafood Heat Pump Dryer

.jpg)