What is the Price for Pepper/Chilli Dryer Machine

Why we use the pepper/chilli dryer machine?

Pepper is a large amount of condiment with great economic value. Pepper is also a seasonal vegetable. The ripening period is very concentrated and the moisture is large. When the pepper is ripe and harvested, it is easy to accumulate a lot. If these fresh peppers are not properly processed and handled, it will cause a lot of waste. Many manufacturers will process a large amount of pepper, but there will still be a lot left. If only rely on the sun upon and artificially dry the peppers, it will not only waste time but also cause a lot of waste of peppers. Because of this feature, it is necessary to adopt a fully automatic pepper dryer, which can achieve the drying of large quantities of pepper in a short period. Many manufacturers and farmers have purchased pepper dryers.At present, the main types of pepper dryers produced by Baixin Machinery Company are pepper drying room and mesh belt type pepper dryer. The types of drying equipment are different, the materials used are different, and the price is also very different. At present, the pepper dryer in our factory is based on the types of commonly used equipment, and when purchasing, reasonable planning and collocation can be carried out according to the size of the pepper processing, the drying needs, and the capital budget.

What is the price for small size pepper/chilli dryer?

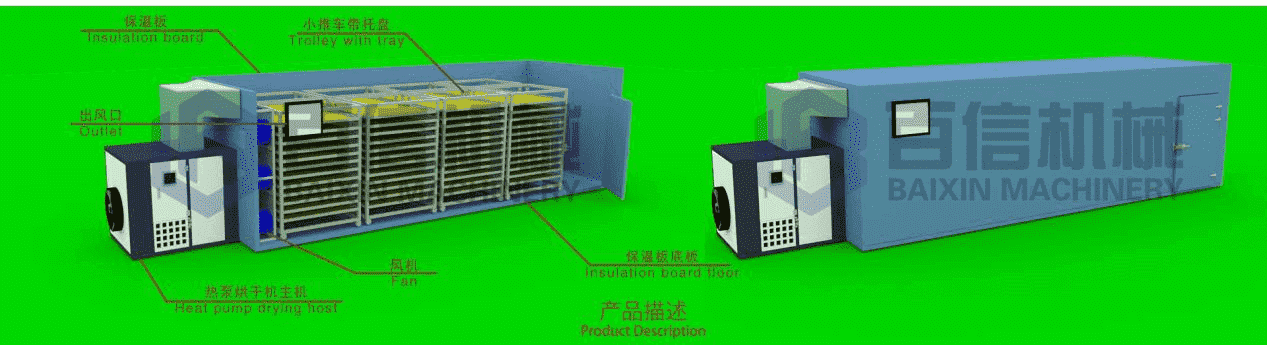

The pepper heat pump dryer is small. The size of the drying box can be customized. There can be many small trolleys in the box, and there are trays on the small trolleys. The peppers are dried on the trolley. The heat pump is essentially a device for increasing heat. The heat pump dryer uses the reversed Carnot principle to absorb heat from the surrounding environment and transfer it to the object to be heated (objects with higher temperatures). The principle is the same as that of refrigeration. The machines are the same, they all work according to the reversed Carnot cycle, the difference is that the operating temperature range is different. The airtightness around the pepper drying room is very good. The insulation polyurethane insulation board is used. The drying room is equipped with multiple trolleys for materials. The number of trolleys is different according to the size of the drying room. A tray can be placed on the trolley, and the material of the tray can be plastic or stainless steel.This chili oven has a simple structure and a reasonable design. It uses electricity as a heat source. It consumes only one-kilowatt hour per hour, and it is particularly energy-saving, which is more suitable for home and small farms used. The output is between 50kg and 1000kg, and the price is from 3000US$ to 25000US$ per set.

What is the price for large size pepper/chilli dryer?

The mesh belt type pepper dryer is also called a large pepper dryer. It can be used for drying large quantities of pepper. It is a continuous multi-layer mesh belt type pepper drying equipment. The pepper is in the box along with the multilayer drying mesh during the operation of the equipment. Continuously moving, the hot air in the box passes through the mesh belt and the material layer from bottom to top, taking away the excess water in the pepper,-after the layer of mesh belt is dried, it will drop to the next layer and continue to dry until all drying is completed. The mesh belt dryer can dry a large amount of pepper, with fast speed, high efficiency, and saving labor costs. With high production efficiency and large drying output, it is widely used in the pepper processing industry. The drying is uniform and the structure is reasonable. The dried peppers are bright in color and high in integrity. The capacity can be from 200kg per hour to 1000kg per hour, and the price is between 25,000 US$ to 60,000US$ per set. It can also be customized according to customer needs.

The above is the price reference of the small pepper dryer and large pepper dryer. You can choose suitable equipment according to your own production needs. If you are still confused about the choice, you can directly contact our Baixin pepper dryer manufacturer for consultation. After we understand the situation, we will recommend a suitable plan for you to choose. That you can buy a suitable machine with lower price.

Chilli/pepper drying video:

Previous post:

Next post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.