Vegetable Drying Machine

Introduction of Drying Vegetables

In the vegetable harvest season, once there is a problem of slow sales or continuous rainy weather, a large number of vegetables will rot because they cannot be kept fresh, that causing considerable economic losses to the farmers. For this reason, planting farmers dry and dehydrate the vegetables and sell them as dried vegetables.The dehydrated vegetable products have low water content and can inhibit the activity of microorganisms and enzymes in the tissues effectively, thus prolonging the storage period, reducing the volume and weight, and facilitating storage and transportation. Generally, the moisture content of fresh vegetables is general around 70%-90%, while the moisture content of dehydrated vegetables or dried vegetables after drying is around 6%-8%.

At present, the drying methods of dehydrated vegetables mainly include natural sun drying and artificial drying.

Natural drying is economical, but it depends on the day's weather, and the drying quality is not guaranteed, especially the color of the vegetables, and the water storage is also prone to insects. With the development of technology, more and more vegetable growers choose dryers to dry vegetables.

Hot Air Recycling Drying Machine Introduction

Baixin agricultural deep processing equipment is special drying equipment designed and produced according to the physical characteristics and dry material requirements of agricultural and sideline products such as fruits, vegetables, medicinal materials, and grains. It uses pure hot air generated by a heat exchange furnace to turn over multiple layers and dry layer by layer. dry. This machine is quick to dehydrate and dry, easy to operate, and efficient in operation. It can meet the needs of large-scale continuous production while retaining the nutrients and colors of the products to the greatest extent.The dehydrated vegetables that have been dried using the special mesh belt dryer from Baixin company have good color, low breakage rate, and high yield. The mesh speed, temperature, and humidity can be adjusted according to production needs to meet the drying treatment of dehydrated vegetables with different moisture content and different varieties.

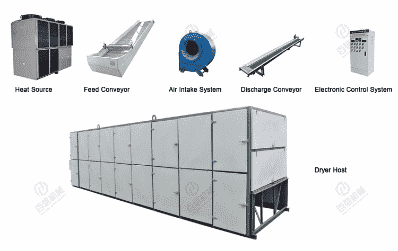

Composition of Vegetable Dryer With Hot Air Circulation

Baixin mesh belt type dehydrated vegetable dryer is composed of 4 parts: feeding conveyor, drying system, heat source, and discharging conveyor.

The feeding conveyor has a material homogenizing device to spread the material evenly. The gear can be adjusted to set the thickness of the dehydrated vegetables according to the drying requirements of dehydrated vegetables to achieve the purpose of uniform feeding. The feeder does not require an additional transmission device and is driven by the motor of the drying system.

The contact surface of the drying cabinet body is made of 304 stainless steel, food-grade material, which will not pollute dehydrated vegetables. Each layer is equipped with a locking device to ensure that the dehydrated vegetables are uniformly transported and dried in an s-shape. The inner frame of the dryer is supported by a hot-dip galvanized steel pipe with anti-corrosive and will not damage or pollute the dehydrated vegetables. The main purpose of all the design of the cabinet is to maximize the use of heat energy. The main purpose of the opening at the top of the cabinet is to remove moisture. The dehydrated vegetables themselves have a certain thickness, so the heat generated inside the dehydrated vegetables generates internal heat and evaporation heat to avoid high humidity and dryness. The air volume is large and the wind pressure penetrates, and there is no need to close it, and the generated steam can be discharged.

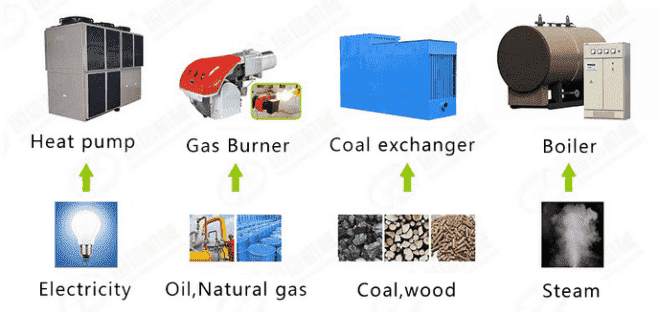

The heat source includes coal, air energy heat pump, natural gas, diesel, steam, biomass particles, and other heat sources, which can be configured according to the actual local conditions of the customer.

Hot Air Circulation Vegetable Drying Applications

It is applied to dry various materials such as fish, vegetables, fruits, herbs, mushroom, sea cucumber, etc.delicate design and multi-function making it favored by clients worldwide.

Technical Data of Vegetable Dehydrator Machine

.png)

Vegetables drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.