How to Choose the Right Vebetable Dryer/Vegetable Dryer Price

How to choose the right vegetable dryer/vegetable dryer price:

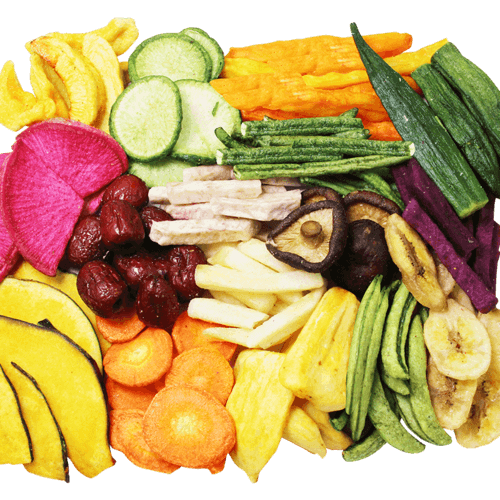

Dehydrated vegetables, also known as rehydrated vegetables, are dried vegetables made by washing and drying fresh vegetables to remove most of the moisture in the vegetables. The original color and nutrient composition of the vegetables remained unchanged. It is not only easy to store and transport, but also can regulate the off-peak season of vegetable production effectively. When eating, it can be restored by immersing it in clean water and retain the original color, nutrition, and flavor of the vegetables. Compared with other fresh vegetables, dehydrated vegetables have the characteristics of small size, lightweight, recovery in water, and convenient transportation and consumption. It is not only delicious and fresh in color when eaten, but also can maintain the original nutritional value.Drying vegetables has solved many unfavorable factors. It can be said that resources are reused. Otherwise, a large number of seasonal vegetables will be put on the market, which will cause a waste of resources. Vegetables that cannot be eaten are dried and processed, and they can be sold all year round and do not affect the taste.

Different drying method of vegetable and why choose vegetable dryer:

There are natural drying and machine drying. The two methods have their advantages. The advantage of natural drying is that it does not cost money, but it costs a little labor. If the quantity is not large, then this method is very suitable. But if more vegetables need to be dried, then use machine drying. After all, this drying method is not restricted by the weather, it can be carried out 24 hours, and the speed is fast, but the traditional coal, oil, and firewood drying is not seen now and replaced by a drying dehumidifier, Then why is this?The reason is simple. There are many shortcomings of traditional drying. One is that the heat is uncontrollable, and the quality of the baked product cannot be guaranteed. The other is that it pollutes the environment and can cause a fire if it is not careful. Therefore, it is banned by the state. The dry dehumidifier went to the front of the vegetable drying. Compared with traditional drying, it is stable, energy-saving, efficient, safe, environmentally friendly, and intelligent.

What is the price for Different vegetable drying machine:

1)Continuous mesh belt vegetable drying machine priceThe automatic Continuous mesh belt multi-layer dryer is a batch, continuous production drying equipment, mainly used for dehydrated vegetable processing, pepper drying, traditional Chinese medicine drying, fungus drying, wolfberry drying, longan drying, shrimp skins, prawns and fish drying, potato chips and other products drying. The main heating methods are electric heating, gas heating, diesel heating, biomass heating and steam heating.

At the same time, the vegetable dryer is designed to use a multi-layer belt structure to dry layer by layer, similar to manual turning to ensure the thoroughness of the material drying. The machine is dried layer by layer from bottom to top, and the moisture of each layer is kept for several hours to maintain the original color of the vegetables without excessive deviation. At the same time, the hot and humid wind blown out by the machine and also initiates a protective effect on the original color of the vegetables to a certain extent.

The machine size has 6m, 9m, and 12m with 4 layer, 5 layer and 6layer according to different customer needs. The capacity can be from 200kg/h to 2000kg/h. The price is from 30000US$ to 60000US$.

2)Heat pump batch production dryer machine price

Different temperature, time, color and moisture content during drying should be determined according to different vegetables. Drying is generally carried out in a drying room. Spread the vegetables evenly on the tray, and then put them on the pre-set trolley rack, keep the room temperature at about 50 ℃.The general drying time is about 5 hours.

It is not restricted by the weather, whether it is cloudy or rainy, day or night, windy or snowy, stable operation all-weather; drying operation costs only 40% of fuel drying equipment, 60% of coal-fired dryers and 30% of electric heating dryers. Compared with ordinary drying equipment, it can save more than 60% energy. Adopting a closed dehumidification mode, no need to discharge waste heat to the outside world, quickly discharging water without losing heat; no flammable fire, explosion and other hazards; no pollution to the dried materials, no pollution to the environment, to achieve 0 Discharge; as long as the range of temperature and humidity is set, the unit will automatically run with one button and no need for special guards. It is a good choice for vegetable drying.

The machine size has 1P, 3P, 8P, 15P and 20P according to different customer needs. The capacity can be from 50kg/batch to 2000kg/batch. The price is from 3000US$ to 30000US$.

If you want to dry vegetable in large quantities, it is recommended that you use a dryer to dry vegetable. Baixin Machinery is a manufacturer specializing in the production of dryers. It has 20 years of rich experience. For food drying, it has professional drying equipment and mature drying technology to ensure the perfect drying effect.

Vegetable drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.