How to Make Dried Vegetables/All the Methods to Make Dried Vegetables

Why do people dry vegetables:

The moisture content of dried vegetables is very low, so bacteria, yeasts and molds cannot use the nutrients in the vegetables to reproduce, so the vegetables will not spoil. At the same time, the reduction of moisture also inhibits the activity of the enzymes contained in the vegetable itself, so that the product can be stored for a long time under dry conditions. After drying, vegetables will become lighter, smaller in volume, and have higher sweetness and better flavor than fresh vegetables.Method of drying vegetables:

The methods of drying vegetables include sun drying, microwave drying, dehydrator drying, oven drying, hot-air drying, and freeze-vacuum drying. At present, hot-air drying and freeze-vacuum drying are more commonly used for vegetable drying. Freeze-vacuum drying is the most advanced vegetable drying method at present, which can not only retain the original color, aroma and taste of fresh vegetables, but also quickly restore moisture.How to dry vegetables at home:

Wash the vegetables, drain the water, and then cut the vegetables. Prepare a sieve for drying. Arrange the vegetables evenly. Do not stack them. Place them in a well-ventilated place with sufficient sunlight to dry. The vegetables need to be turned repeatedly during the drying process. The drying time is about 1 week, and it is not completed until the moisture of the vegetables has completely evaporated. Different vegetables require different time to dry, which can be judged by the appearance of the vegetables. Sun-dried vegetables can be stored for 3 weeks at room temperature.Tips:

If you encounter rainy or humid weather, you can move vegetables to indoor ventilation or put them in the refrigerator. If you are worried about being contaminated with dust, you can cover it with a light-permeable and air-permeable dust-proof net.How to dry vegetables in microwave:

After cutting the vegetables, place them evenly on the tray and put them in the microwave. Heat in the microwave for about 3 minutes, turn the vegetables over, and reheat for about 2 minutes.How to dry vegetables Use a dehydrator:

Arrange the cut vegetables evenly on the tray, not overlapping them. If you use pre-treated vegetables, it is better to lightly spray the tray with vegetable oil, otherwise it may stick to the tray. Preheat the dehydrator to 63°C, put the tray into the dehydrator, then lower the temperature to 57-60°C, and dehydrate for about 1 hour. The time depends on the power of the dehydrator, the thickness and water content of the vegetables.How to dry vegetables in oven:

Arrange the cut vegetables evenly on the tray. Put it in the oven and set the temperature to 50-60℃ for 30 minutes. During the drying process, open the oven door slightly to allow excess moisture to escape.How to preserve vegetables:

1. Put the dried vegetables in a fresh-keeping box or an airtight jar, and store them in a cool and ventilated place, which can be stored for about half a year.2. If there is no fresh-keeping box or airtight jar at home, put the dried vegetables in an airtight bag and put it in the refrigerator. It can be stored for about half a year.

Methods of drying vegetables in large quantities:

Hot air drying

1. Material selectionChoose vegetables with rich meat quality to remove pests, rot and wilted parts. Rinse the vegetables with clean water, and then dry them in a cool place, but they should not be exposed to the sun.

2. Blanching

Cut the washed vegetables into slices, silks, strips and other shapes according to product requirements. During pre-cooking, due to the different raw materials, the vegetables that are suitable for being cooked are boiled in boiling water, and those that are not suitable for being cooked are boiled in boiling water for a while (the water temperature is generally above 150°C). The general blanching time is 2-4 minutes. Leafy vegetables are better not to be blanched.

3. Cool and drain

The blanched vegetables should be cooled immediately (usually cooled by cold water, so that they can quickly drop to room temperature). After cooling, in order to shorten the drying time, a centrifuge can be used to shake the water. After the water is drained, the vegetables are spread out to dry, and then placed in a tray.

4. Drying

Put the vegetables on the drying rack and control the temperature at 32-42℃. Enter the drying room every 30 minutes to check the temperature. At the same time, turn the vegetables in the baking tray to speed up the drying speed. Generally after 11-16 hours, when the moisture content of the vegetables drops to about 20%, 0.1% sorbic acid, sodium bicarbonate, sodium benzoate and other antiseptic and fresh-keeping agents can be evenly sprayed on the surface of the vegetables.

5. Put the vegetables in a sealed wooden box for about 10 hours to keep the moisture content of the dried vegetables uniform.

6. Packaging

Dried vegetables can be sealed and packaged after inspection.

Freeze vacuum drying

1. Selection of materialsLeafy vegetables should not exceed 24 hours from harvest to processing. Remove yellowing and rotten parts.

2. Rinse

Rinse the vegetables with clean water, and remove the stems, dry leaves and sticks. To remove pesticide residues, generally use 1.55%-1% hydrochloric acid solution or 0.05%-0.1% potassium permanganate or bleaching powder to soak for several minutes, and then rinse with clean water. Dry the vegetables in a place where there is no sun.

3. Peel

Root vegetables should be peeled. Use chemical lye, manually or mechanically to peel. After peeling, immediately put them into clean water or color protection liquid to prevent vegetables from browning.

4. Cut vegetables

According to the product requirements, cut the vegetables into slices, silks, strips, etc. The vegetables that are easy to brown after cutting should be immersed in the color protection liquid.

5. Blanching

Hot water is generally used for blanching, and the water temperature varies with vegetable varieties, generally above 100°C. After the vegetables are put in the pot, keep turning them to make them evenly heated. The time varies from a few seconds to a few minutes. When blanching, you can add some salt, sugar, organic acid and other substances in the water to change the color of vegetables and increase the hardness.

6. Cool down

The boiled vegetables should be placed in cold water to cool immediately.

7. Drain the water

After cooling, there will be some water on the surface of the vegetables, which will easily cause the freeze-dried vegetables to clump, and it is not conducive to the next step of vacuum drying. The centrifugal drying method is generally used to drain the water.

8. Lyophilized

After draining the water, put the materials into the freeze dryer, and the temperature is generally set below -30°C.

9. Vacuum drying

Put the freeze-dried vegetables into a vacuum container, and the heating system will supply heat to the materials to evaporate the moisture of the materials until the vegetables are completely dry.

10.Check

Freeze-dried products should be inspected, and impurities and substandard products should be removed.

11. Packaging

Since the product is easy to oxidize and brown, it can be filled with nitrogen in the package.

If you need to dry a lot of vegetables, Baixin Machinery’s drying equipment is a good choice. Baixin Machinery is a manufacturer specializing in the production of dryers. It has 20 years of rich experience. For vegetables drying, it has professional drying equipment and mature drying technology to ensure the perfect drying effect.

Baixin Machinery’s most popular vegetable dryers are heat pump dryers and continuous mesh belt dryers.I would be happy to introduce these two dryers in detail for you:

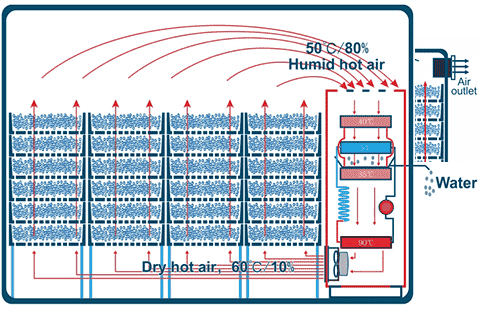

1:The first method:vegetable heat pump dryer

Household Commercial All-in-one drying equipment without installation for any materialDrying essence is take moisture away, but takes away the moisture temperature is not the most critical factor. The key for drying is depending on relative humidity within certain space, Baixin Company took advantage of the dry essence, originality developed a "Closed Cycle" dryer, changed the traditional heat pump dryer "bake" to "dehumidifier”. Its several advantages were unmatched by the traditional heat pump dryer.

Baixin Food Dehydrator has a compact structure, great energy-saving, wide application, high drying quality, easy operation, simple installation and removable. it is the best drying equipment for small firms, drying experiment and scientific research. The users only connect the power to use, is the easiest operation heat pump dryer.

2:The second method: vegetable continuous mesh belt drying machine

Large amount of dehydration 200-5000kg/h vegetables drying machine continuous automatic work easy operationVegetables dryer machine is a kind of continuous production drying equipment, the main heating way has electric heating, steam heating, hot air heating. Its main working principle is to spread the material evenly in the network. The material is moved in the dryer by the operation of the machine, and the hot air draws out the water vapor of the material. so as to achieve the purpose of drying.

The operation temperature is 40-120 degree centigrade. And the dry cycle is 1-5 hours.

Vegetables drying video:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.