How to Choose the Right Food Dryer/Food Dryer Price

How to choose the right food dryer/food dryer price:

Food is the most basic material for human survival and development. While human beings never satisfy their food needs, they also promote and develop food production continuously. Safety is the most basic requirement of food and the primary criterion for consumers to choose food. In recent years, food safety issues have attracted widespread attention from the whole society.When food cannot be stored for a long time, humans have learned to refrigerate and dry storage. In the past, there was no way to refrigerate, and dry storage has become a common storage method used by people. In the past, drying storage was mainly based on sun drying. Nowadays, with the development of society and technology infiltrating life, a large number of manufacturers and processors have chosen dryers to dry food. Of course, some businesses are still using traditional drying methods to dry the food. What is the difference between traditional drying and dryer drying:

The difference between sun drying and dryer:

Sun-drying:1:It occupies a large area and requires a large drying yard to meet mass production;

2:The labor intensity is high, and the materials need to be turned frequently under strong ultraviolet rays, and more and more workers are no longer willing to take up this position;

3:Poor sanitary conditions cannot prevent the breeding of flies and insects. Some unhealthy workshops rely on spraying insecticides to reduce insect pests, and food safety cannot be guaranteed;

4:The temperature and humidity are difficult to control, and the uniformity, color, and appearance of product quality cannot be guaranteed;

Dryer drying:

1:The floor area is only the size of the dryer. Generally, the dryer occupies an area of 50-100 square meters; the intelligent integrated drying of the dryer does not require a large number of manual guards;

2:The dryer is fully enclosed drying;

3:Close to natural drying, more intelligent temperature control;

In summary, the dryer can better ensure the safety and health of food. It is understandable to use the traditional drying method when there is no choice. Nowadays, with advanced technology, choosing a dryer for drying food is the best choice.

Basic concepts of food dryer technology:

The food dryer technology uses heat to decompress and evaporate in the evaporator so that the surface temperature of the evaporator is lower than the indoor air dew point so that when the air flows through the evaporator, it is cooled and lowered to a certain temperature. At this time, the excess steam in the air will condense and precipitate on the surface of the evaporator. After the condensed water drips into the drain pan, it flows into the water container through the ventilation pipe.After the normal working medium absorbs heat and vaporizes, it is sent to the condenser through the fan's work, and the condenser releases a large amount of latent heat of vaporization under high temperature and high pressure. When the air-cooled in the evaporator passes through the condenser, after the heat absorption temperature rises, it is discharged in a dry state and mixed with the indoor air. Thereby the indoor air humidity is reduced, and the purpose of drying and dehydration is achieved.

Precautions related to food drying:

1. Temperature: The drying of food is generally divided into two categories: dry and wet. Dry food generally uses high temperature and fast-drying; wet food mainly uses low temperature and slow drying.2. Humidity: food generally has large water content, so controlling the moisture content is an important factor in determining the drying quality; in addition, the moisture of meat foods exists in fat and oil, dehydration is difficult, and it is critical to control the dehydration speed important.

3. Circulating air: Food drying generally requires a large air volume and wind speed to take away the surface moisture as soon as possible to prevent the moisture from staying on the surface of the material for a long time and thus affect the drying speed.

Price for food dryer:

The equipment can be customized according to product output, production process and site size according to different requirement for different customer. The price for continuous mesh belt food drying machine and heat pump food drying machine are not the same. You can choose the right one according to your actual situation. As a professional manufacture of drying machine for years, Baixin company can give you best service and let you choose the right machine for your need to make more profit for your business.

If you want to dry food in large quantities, it is recommended that you use a dryer to dry food. Baixin Machinery is a manufacturer specializing in the production of dryers. It has 20 years of rich experience. For food drying, it has professional drying equipment and mature drying technology to ensure the perfect drying effect.

The most popular food dryers of Baixin Machinery are heat pump dryers and continuous mesh belt dryers. I will introduce these two dryers in detail for you:

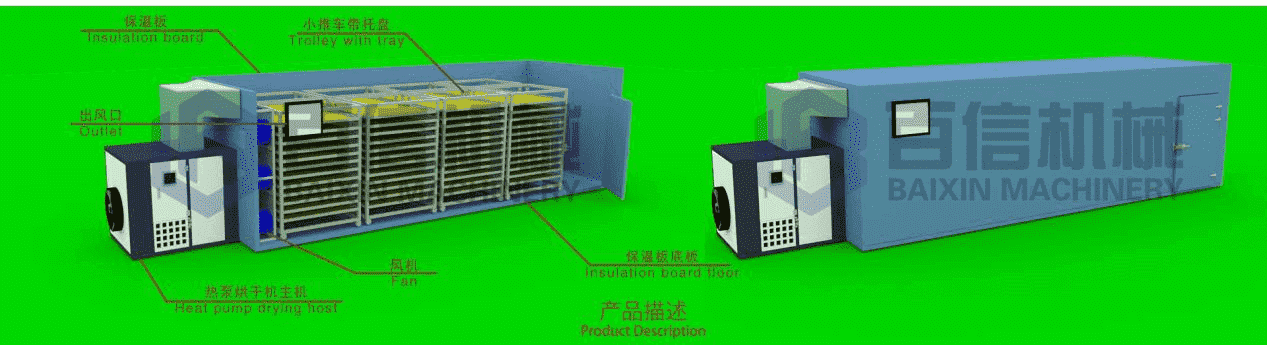

1:The first method:food heat pump dryer

Commercial 100-3000kg/h large amount of dehydration wide application and easy operationHeat pump drying machine use the principle of inverse Carnot cycle. It absorbs low-temperature heat energy in the air, which becomes high-temperature heat energy after efficient heat collection and integration by the heat pump system, and is transported to the drying room for cyclic heating and drying of materials.It refers to exhausting the hot and humid air in the drying room directly to the outside of the drying room through dehumidification device, and then replenishing natural fresh air.

Hot air circle drying machine belongs to high temperature heat pump unit. Its working principle is: the working fluid of the heat pump is compressed by the compressor, becomes high temperature and high pressure gas, enters the condenser, condenses and liquefies the heat, and is used for air heating in the drying room. The moisture in the material is vaporized and evaporated by the form of hot air, and the evaporated water vapor is discharged by the moisture discharge system, thereby achieving the purpose of drying the drying material.

2:The second method:food continuous mesh belt drying machine

Large amount of dehydration 200-5000kg/h food drying machine continuous automatic work easy operationFood dryer machine is a kind of continuous production drying equipment, the main heating way has electric heating, steam heating, hot air heating. Its main working principle is to spread the material evenly in the network. The material is moved in the dryer by the operation of the machine, and the hot air draws out the water vapor of the material. so as to achieve the purpose of drying.

The operation temperature is 40-120 degree centigrade. And the dry cycle is 1-5 hours.

Food drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.