Dehydrate Silkworm Cocoon in a Dehydrator/Silkworm Cocoon Dryer

Why Dry Silkworm Cocoons?

Cocoon refers to the cocoon of the silkworm, which is oval or thin in the middle. The cocoon is white, yellow, light green, and other colors, with a length of about 3-4 centimeters and a diameter of 1.7-2.1 centimeters. The surface is white with irregular wrinkles, and it is will form with attached silk. The Cocoon layer can be used as raw material for silk floss and spun silk. More importantly, silkworm cocoons are rich in protein and vitamin B, which can be used for pharmacy and extraction of pupa oil and livestock feed and can relieve internal heat and stop bleeding and effectively prevent various diseases.The purpose of drying silkworm cocoons is to prevent them from turning into moths during storage, and the parasitic flies left in silkworm bodies turn into maggots, which leads to the decay of pupae and destruction of cocoon layers. In addition, after treatment, the solubility of the cocoon layer of dried silkworm chrysalis is easily changed, which enhances the resistance, protects the soothing of the cocoon, and is more conducive to storage. Generally speaking, in silkworm cocoons, the water content of the cocoon layer accounts for only 18-24%, while that of the pupa body accounts for about 73-77%. Therefore, drying cocoons is mainly to remove water from pupae, and only a little amount of water is lost in the cocoon layer.

How to Dehydrate Silkworm Cocoon in a Dehydrator?

Generally, large cocoon dryers with hot air circulation are used to dry cocoons. The cocoon dryer provides heat from a heat source, and then sends hot air into the drying chamber through a fan to form different temperature zones in the drying chamber. The cocoons are put into the mesh belt of the drying chamber to move, and then automatically rotated and turned from the first layer to the last layer, and then sent out of the drying chamber, so that they can be packed separately. The PLC control is simple and intuitive, and the temperature control is more accurate. Here are the detailed steps.The cocoon drying process is divided into three stages: preheating, constant speed drying, and deceleration drying.

- Preheating stage: When the cocoon is heated, the heat energy can enter the cocoon cavity through the cocoon layer to kill the pupa, so that the water content of the pupa enters the evaporation period.

- Constant speed drying stage: This is the stage of pupa evaporation and the fastest evaporation time. At this stage, the moisture diffusion rate of the pupa is in balance with the evaporation rate of the cocoon surface, and the temperature of the cocoon layer is lower than that of the silkworm layer, and the temperature of the pupa body is lower than that of the cocoon layer until the moisture diffusion rate of pupa body is lower than that of cocoon layer surface.

- Deceleration drying stage: This is a period when the moisture in cocoons gradually decreases and the evaporation rate correspondingly slows down. During this period, the temperature of the cocoon was close to the hot air. Evaporation and drying in pupae decelerate until drying is finished.

The Principle of Dryer Machine Working

The silkworm cocoons dryer is a continuous production drying equipment. The main heating methods are electric heating, steam heating, gas heating, and coal heating. The main principle is to spread the material on the mesh belt evenly and drag it into the dryer machine by the transmission device. Moving back and forth, hot air flows through the materials, and water vapor is discharged from the moisture drain hole to achieve the purpose of drying.

The Silkworm Cocoons Dryer Structure

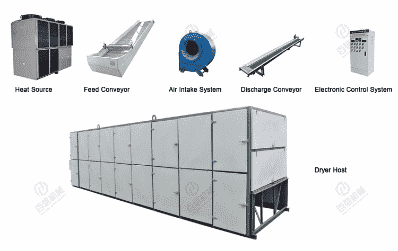

The silkworm cocoons drying machine is composed of 4 parts, that is the feeding conveyor, the main unit of the mesh belt dryer, the heat source, and the discharging conveyor. The conversion furnace provides heat; the through-flow mesh belt dryer is the main body of the drying equipment, which is composed of cabinet body and a multi-layer conveyor belt; the electric control system controls the start, operation and stop of the entire equipment. With the cooperation of other auxiliary components, the drying equipment completes the food feeding, drying and discharging processes, realizing the drying process of silkworm cocoons drying.

Technical Data of Silkworm Cocoons Dehydrator Machine

.png)

Silkworm Cocoons drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.