Onion Drying Plant

Onion Drying Plant

Onions play an important role in our daily diet. Eating onions regularly can enhance our immunity and resist aging. However, fresh onions have a short shelf life, and in rainy weather, the onions may rot. Therefore, drying onions is not only good for preservation, but also provides more options for cooking methods. Some dried onions have entered the market and are deeply loved by people. So what are onion drying plants? How to choose a suitable onion drying plant? Now, Baixin Drying Company will share with you several onion drying plants that are energy-saving, environmentally friendly, convenient, and have very good drying color and luster quality.

How to choose a suitable onion drying plant?

Onion drying plant are divided into three types: mesh belt onion drying plant, onion drying room and all-in-one onion drying plant.In terms of output, the continuous mesh belt onion drying plant is suitable for manufacturers with large output. Its output is 300-2000kg/h. The output of the onion drying room plant is smaller than that of the mesh belt onion drying plant, and the output is 100-5000/batch. The output of the all-in-one onion drying plant is the smallest, and its output is 100-1500/batch. It is suitable for agricultural plants or small processing plants. Oven length and mesh belt layers can be customized. We can choose and match them reasonably according to our own processing requirements.

1. All-in-one onion drying plant

The first onion drying plant is the all-in-one onion drying plant with the smallest yield.

The drying principle is the same as that of the onion drying room plant. The all-in-one onion drying plant is equipped with a cart with trays and tray racks. When drying onions, we put them in trays, put them on the tray racks of the cart, and then push them into the onion drying chamber for drying.

The heat source of the onion integrated drying is air energy. The heat in the air is absorbed by the heat pump compressor. After compression and release, a large amount of high-temperature hot air can be obtained, so as to achieve continuous and uniform drying and processing of onions. The operation of this all-in-one drying unit is relatively simple, simply plug in and dry.

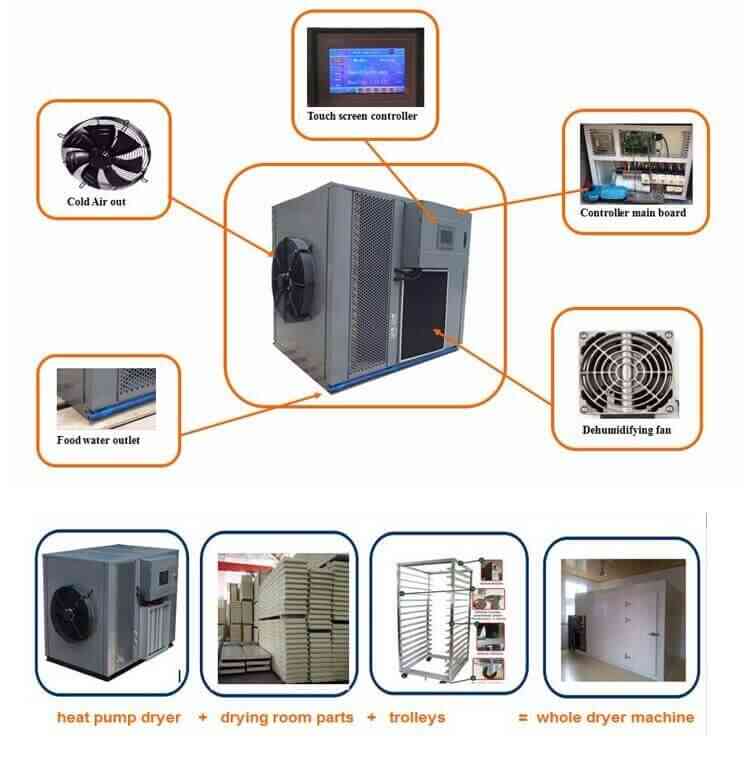

Components of all-in-one onion drying plant

One set all-in-one onion drying plant contains: power jack, water outlet,exhaust air outlet, supporting wheels, PLC controller pancl, door lock, observation window,circulating air inlet, outlet for hot and dry air, PP tray, stainless steel tray, supporting racks for trys. The onion all-in-one plant has compact structure, good energy-saving effect, wide application range, high drying quality, convenient operation, simple installation and disassembly. It is the best drying equipment for small businesses, drying experiments and scientific research. The user only needs to connect the power to use, it is the easiest to operate onion drying plant.

Advantages of onion dehydartion room machine

1. Stainless steel 304 material. The whole plant uses stainless steel material, can work a long time, and keep better heat preservation, bottom have wheeler, can move easily.

2. Great energy saving. Heat pump system design, low energy consumption, can save 75% energy than traditional electricity element heating.

3. Wide application easy operation. Fit for wide application, seafood, fruit, onion, spice, herbs, etc all can use it to dry.

4. Gentle drying. Temperature range 40-80°C, low temperature dehydrate processing can better keep material nutrition, during drying, no need to move the plant.

Technical parameters of all-in-one onion drying plant

| All-in-one onion drying plant list | ||||||||

| type | plant size(MM) | Capacity (KG) | power | total power(kw) | Qty of cart | Qty of tray | cart size(MM) | tray size(MM) |

| 1P | 1180×680×1800 | 50-80 | 1 | 1 | — | 15 | — | 600×800 |

| 3P | 2100×930×2100 | 120-300 | 3.5 | 3.5 | — | 40/60 | — | 600×800 |

| 8P | 4000×1960×2050 | 650-1000 | 8 | 8 | 8 | 232 | 600×800 | 600×800 |

| The drying plant can be equipped according to the user's requirement and the production demands. | ||||||||

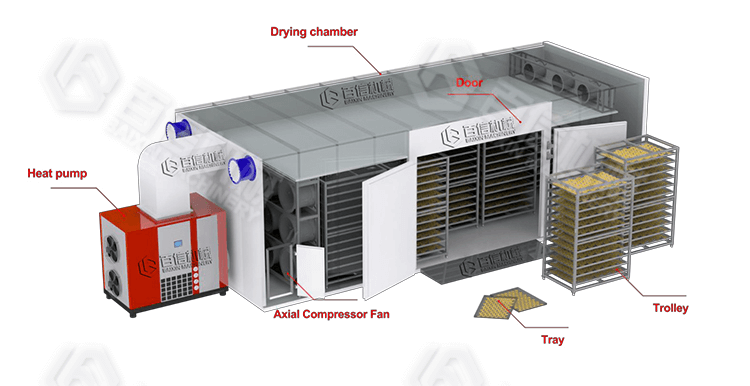

2. Onion drying room plant

The second type of drying plant is the onion dryer room.The onion drying room plant is equipped with a trolley with trays and tray racks. When we dry the onions, we put the onions in the tray, on the tray rack of the cart, and push it into the onion drying chamber to dry. Onions are putted on the shelf car and enter the closed cycle drying room for drying without any pollution in the process. The heat source of the onion drying room is air. The heat in the air is absorbed by the heat pump compressor. After being compressed and released, a large amount of high-temperature hot air can be obtained, so as to achieve uniform drying and processing of onions.

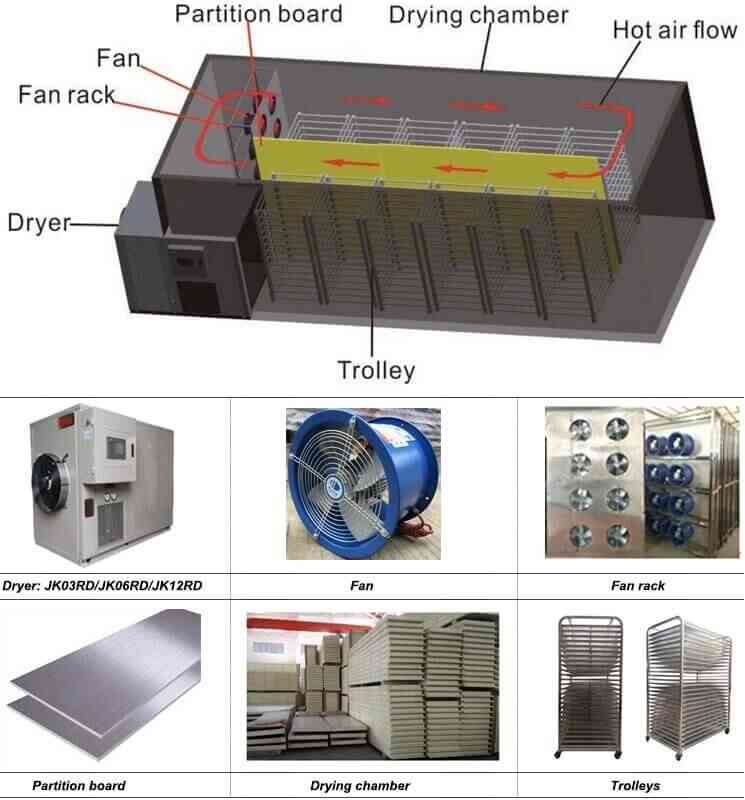

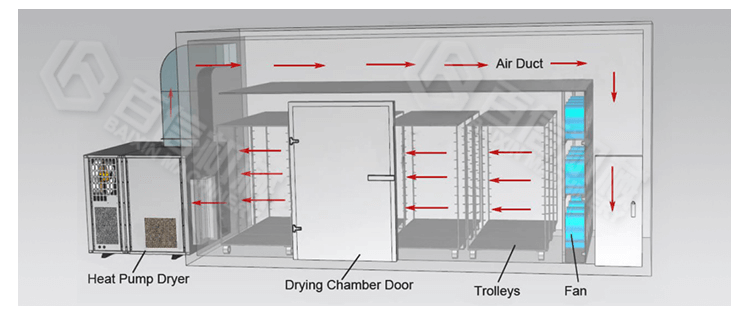

Components of onion drying room plant

One set onion drying room plant contains: heat pump drying host, drying chamber, fan frame with fan, trolley with tray. The drying chamber is used 100mm polyurethane insulation board, supporting 304 stainless steel trolleys and trays. Put the onions into the material tray, insert the material tray into the material cart and push it into the drying room, and close the sealing door to start drying production. The drying temperature range is 65 ℃ - 85 ℃, and the drying temperature is divided into different temperatures, and the temperature is gradually lowered. Generally, the drying time is about 8-10 hours to complete a batch.

The working principle of onion drying room plant

The onion heat pump drying plant uses the reverse Carnot principle to let the hot air circulating blower dry the vegatable. Heat Pump Drying Compressor Heat Exchanger Blocked Radiator (External to Plant). Compressor and other equipment make up the refrigerant circulation system. The fan impeller rotates, the outside air enters the oven, passes through the heater, forms hot air, and then enters the studio through the gap of the air distribution plate, and a large amount of hot air in the circulating flow continues to enter the new air inlet for supplementation. The moisture discharged after recovery is discharged from the exhaust port. The whole cycle makes the vegatable heated evenly and achieves the purpose of drying.

Technical parameters of onion drying room plant

| heat pump onion drying plant list | ||||||||||

| type | plant size(MM) | Capacity (KG) | power | Qty of fan | fan power | total power(kw) | Qty of cart | Qty of tray | cart size(MM) | tray size(MM) |

| 3P A | 3500×2200×2200 | 200-400 | 2.25 | 6 | 0.25/pc | 3.75 | 6 | 78 | 670×810 | 600×800 |

| 8P A | 5300×2200×2800 | 450-750 | 6 | 12 | 0.37/pc | 10.44 | 6 | 156 | 1210×870 | 600×800 |

| 15P | 7500×3000×2800 | 900-1500 | 11.25 | 12 | 0.55/pc | 17.85 | 12 | 312 | 1210×870 | 600×800 |

| 1P D | 1180×680×1800 | 50-80 | 1 | — | — | 1 | — | 15 | — | 600×800 |

| 3P D | 2100×930×2100 | 120-300 | 3.5 | — | — | 3.5 | — | 40/60 | — | 600×800 |

| 8P D | 4000×1960×2050 | 650-1000 | 8 | — | — | 8 | 8 | 232 | 600×800 | 600×800 |

| The drying plant can be equipped according to the user's requirement and the production demands. | ||||||||||

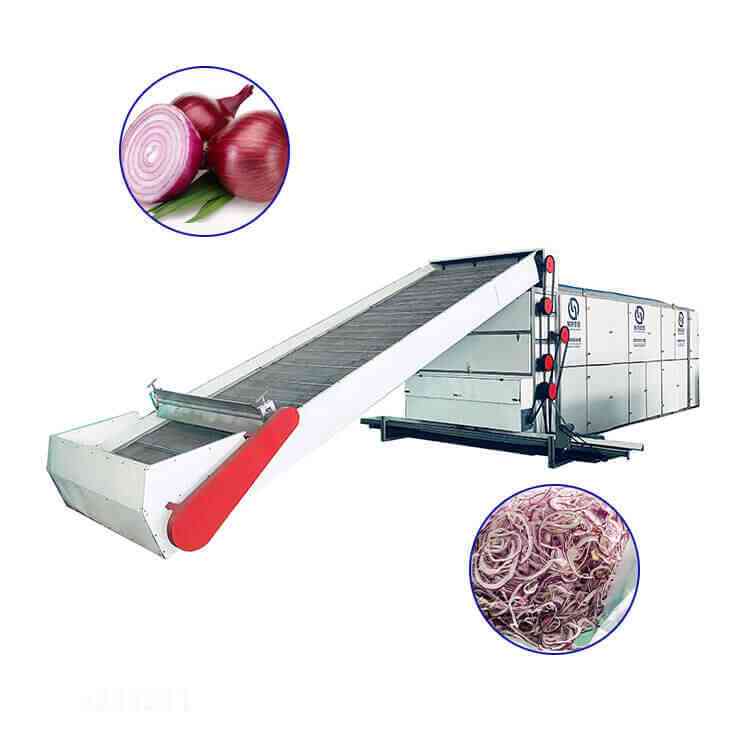

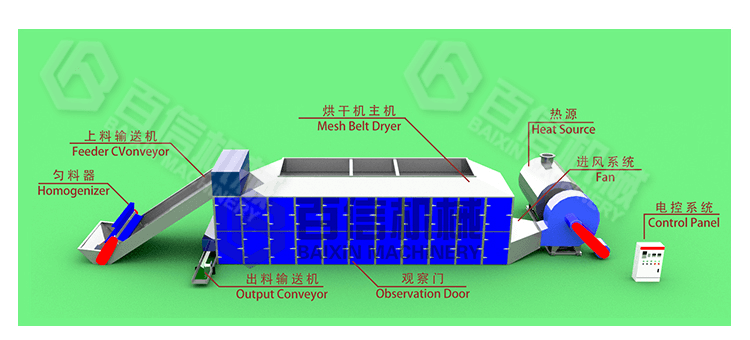

3. continuous mesh belt onion drying plant

Lastly, let's take a look at the continuous mesh belt onion drying plant with the largest output. Mesh belt onion drying plant have a wide range of heat sources such as coal heating, gas heating, steam heating, biomass pellet heating or electric heating. It is a multi-layer continuous drying structure. When drying onions, just put the onions in the feeding port, and the onions will enter the dryer with the feeding conveyor for drying.Onions are dried and dehydrated layer by layer from top to bottom. The drying speed is fast and the production efficiency is high, which is very suitable for the drying and processing of large quantities of onions.

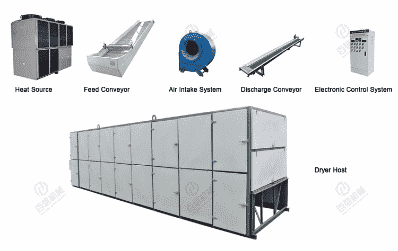

Components of continuous mesh belt onion drying plant

One set continuous mesh belt onion drying plant contains: homogenizer, feeding conveyor,dryer host, output conveyor, observation door, heat source, air intake system, control panel. The onion drying consists of 4 parts, namely the feed conveyor, the main plant of the mesh belt onion dryer plant, the heat source and the discharge conveyor. The reformer provides heat, and the through-flow mesh belt onion dryer is the main body of the drying equipment, which consists of a cabinet and multi-layer conveyor belts; the electrical control system controls the start, operation and stop of the entire equipment. With the cooperation of other auxiliary components, the drying equipment completes the drying and discharging process of food, and realizes the drying process of food drying.

Advantages of onion all-in-one dehydration machine

1. Stainless steel 304 material. The whole machine uses stainless steel material, can work a long time, and keep better heat preservation, bottom have wheeler, can move easily.2. Great energy saving. Heat pump system design, low energy consumption, can save 75% energy than traditional electricity element heating.

3. Wide application easy operation. Fit for wide application, seafood, fruit, vegetable, spice, herbs, etc all can use it to dry.

4. Gentle drying. Temperature range 40-80°C, low temperature dehydrate processing can better keep material nutrition, during drying, no need to move the machine.

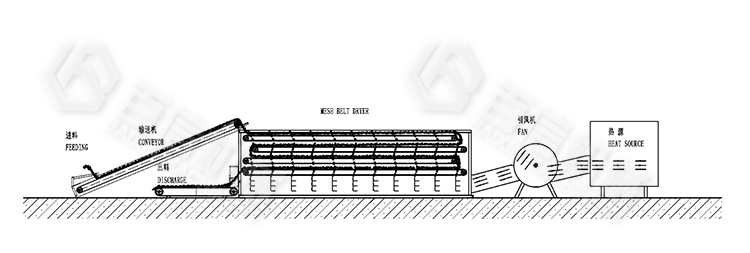

The working principle of continuous mesh belt onion drying plant

Baixin continuous mesh belt onion drying plant is a continuous production drying equipment. The main heating methods are electric heating, steam heating and hot air heating. Its main working principle is to distribute the material evenly in the network. Through the operation of the plant, the onion moves in the dryer, and the hot air extracts the water vapor of the onion. So as to achieve the purpose of drying. The working temperature is 40-120 degrees Celsius. The drying cycle is 1-5 hours. Mainly used for agricultural and sideline products such as fruits and onions, Chinese herbal medicines, etc. The equipment is easy to operate, saves time, has a healthy drying process, and protects the environment.

Technical parameters of mesh belt onion drying plant

| continuous mesh belt dryer list | |||||||

| Model | operation temperature | drying time | thickness of the material | the size of motor | capacity | heat source | total power |

| BX-2*6M | 40-120℃ | 0.5-5h | 50-200mm | 6*2*2.5 | 200-400kg/h | electricity | 66.5kw |

| natural gas/propane | 12.22kw | ||||||

| coal/wood chips | 13.72kw | ||||||

| steam | 11.22kw | ||||||

| BX-2*9M | 9*2*2.5 | 500-800kg/h | electricity | 79.76kw | |||

| natural gas/propane | 20.12kw | ||||||

| coal/wood chips | 23.12kw | ||||||

| steam | 16.62kw | ||||||

| BX-2*12M | 12*2*2.5 | 1000-1500kg/h | electricity | 153.12kw | |||

| natural gas/propane | 33.12kw | ||||||

| coal/wood chips | 36.12kw | ||||||

| steam | 25.62kw | ||||||

Other application areas of continuous mesh belt onion drying plant

The mesh belt onion drying plant is of good quality, the inner and outer dryers are made of stainless steel or paint material. High temperature resistance, corrosion resistance, high strength, no rust, suitable for drying onions, but also suitable for large-scale continuous dehydration and drying of food series, fruit series, pharmaceutical series, agricultural and sideline products.The above is a brief introduction and technical parameters of the three onion drying plants of Baixin drying plant company. The onion drying plants produced by our company support customization. If you are interested in our drying plant or want to know more about the onion drying plant and its price. Please feel free to contact us, and we will get you a satisfactory answer and solution according to your requirements.

Onion drying plant video:

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.