Mushroom Dehydrator/Mushroom Dehydrator Machine

Why do you dry mushrooms?

Mushroom, a fungus that looks like an umbrella when mature. Part of them is edible, and there are currently 36,000 known species. Mushrooms are called Agaricus bisporus and belong to the order Agaricus. Mushroom is a kind of nutritious edible fungus, it is an ideal ingredient for various dishes. The dried mushrooms can not only retain their delicious fragrance but can also be stored for a longer period.

The traditional drying method for mushroom

- Mushrooms can be dried naturally, but when drying mushrooms naturally, one must pay more attention to the temperature and humidity of the surrounding environment. If it is rainy, it is not suitable to dry the mushrooms naturally, which will easily cause the mushrooms to become moldy. Dry the mushrooms naturally, preferably when the weather is good, so that it is easier to dry the mushrooms. Generally, you only need to dry them for about 2 days. Although the methods are simple in operation and low in cost, they are of poor quality. When exposed to the sun, the fungus cover is easy to reverse, dull has no fragrance and is easy to be restricted by the weather.

- The moisture content of the mushroom itself is very high. Generally speaking, most of the edible mushrooms have a relatively large amount of water, and some even require more than 90% of moisture dehydration. The color of the mushroom is also a very important technical indicator. While drying, the color of the mushrooms should be kept stable and not blackened. This is affected by the humidity of the air during the drying process of the mushrooms.

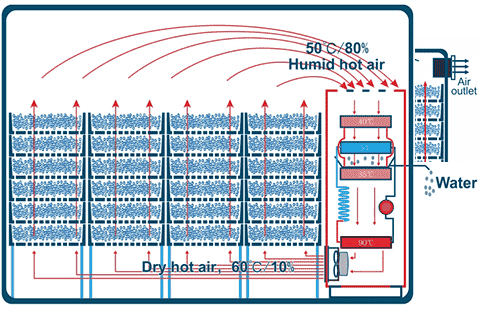

What is the working principle of mushroom dryer

The intelligent air-energy mushroom dryer developed by Henan Baixin Company is a kind of fixed dryer. Fresh mushrooms are placed statically in the drying room. The heat is circulated and transferred through the refrigerant by the function of the evaporator and radiator inside and outside the mainframe. It also absorbs the temperature outside the drying room, transports it to the inside of the drying room, and raises the internal air temperature. When the temperature in the drying room rises, the axial flow fan installed in the drying room blows the heat. The air flows over the surface of the mushroom, the hot air at high temperature will transfer heat to the mushroom, and evaporate the moisture in the mushroom gradually. At this time, the air humidity in the drying room begins to increase, and the high temperature and high humidity air pass through the condensation dehumidifier. At this time, the water vapor in the high-humidity air is condensed into water droplets and then drained through the drainage pipe. The whole process circulates back and forth, the water is evaporated in the material continuously, and then condensed and drained continuously, and the mushrooms are dehydrated and dried in this way slowly.Advantage of mushroom dehydrator/drying machine

- Environmental protection and safety. There is no open flame, no harmful gas, dust, waste residue, and other pollutants, no danger of flammability and explosion, and no damage to the environment.

- High energy saving. When the air energy mushroom dryer is working, electricity is only used to run the dryer, so the power consumption is very low, only 25% of the electric dryer. Mushroom only needs 1.52 kilowatt-hours of electricity, and win customers' favor.

- Simple operation. The air dryer is very intelligent. The user only needs to put the mushrooms in the drying room, and then press the power button, the dryer will work automatically, and it will automatically shut down after drying. The whole process does not require manual monitoring or manual operation. Not only simple and convenient but also improve the work efficiency of workers.

- Fourth, the drying quality is higher. The air dryer has precise temperature control and constant temperature drying. The inside and outside of the drying process are heated evenly to ensure that the inside of the mushrooms are dried completely and the appearance is not damaged. The appearance, color, and nutrition of the mushrooms can be preserved to a greater extent, and the quality of the dried mushrooms is higher, the better it can be sold in the market.

- Strong adaptability. The air energy dryer can set different drying temperatures by itself to meet the drying needs of different materials (such as grains, fruits, seafood, vegetables, etc.), and has a very wide range of applications.

Mushroom dehydrator video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.