Moringa Leaf Processing Machine

Moringa Leaf Processing Machine

Moringa is widely grown in tropical regions such as Southeast Asia and Africa. It has a long history of consumption. It is rich in nutrition and comprehensive. Moringa is considered one of the most nutritious plants ever discovered.

Moringa leaves have many benefits to the human body, and can be used as both food and medicine. The deep processing of moringa leaves has a very good development prospect in the world and has a large market. If you want to start a moringa leaf business, you must have a professional moringa leaf processing machine. Professional Moringa leaf processing makes Moringa leaf higher quality. Next, I will share with you a complete machine of Moringa leaf process.

Moringa Leaf processing Machine

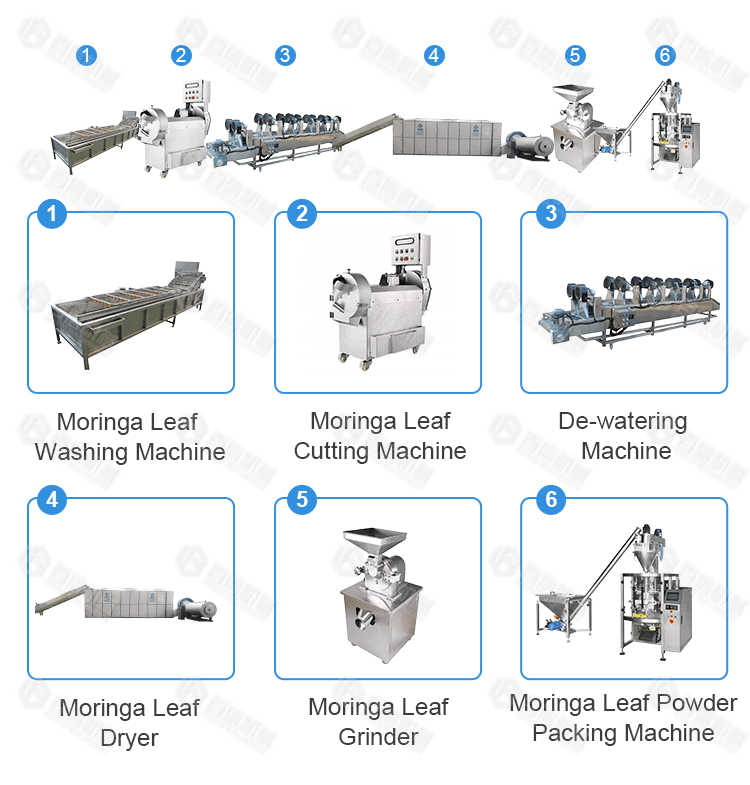

The Moringa leaf processing line has continuous automatic production, fast processing speed, high output and good quality. The picked Moringa leaves are processed into Moringa after being cleaned, air-dried, cut into sections, dried and ground. Moringa leaf processing machine includes moringa leaf washing machine, moringa leaf cutting machine, moringa leaf drying machine, moringa leaf mill, moringa leaf packaging machine and other equipment, which can be used for moringa leaf, moringa leaf and other deep processing.This is the best choice for businesses and the most ideal device.

Moringa Leaf Processing Line Flow Chart

The working process of the moringa leaf processing machine: Moringa leaf cleaning-air drying-cutting-drying-grinding-packaging.

Components of moringa leaf processing line

A complete large-scale moringa leaf processing plant mainly includes: moringa leaf washing machine, moringa leaf cutting machine, moringa leaf drying machine, moringa leaf mill, moringa leaf packaging machine and other equipment.

Moringa leaf washing machine: It is used to clean the dirt, dust and other impurities attached to the surface of Moringa leaves. Moringa leaves are washed and transported under the action of high-pressure water flow and strong air bubbles, and at the same time, appropriate color fixatives and disinfectants can be added to enhance the color of Moringa powder. It is then transported to the next process.

Moringa leaf de-watering machine: Dehydrating Moringa oleifera leaves before drying and air-drying Moringa oleifera leaves can effectively remove water droplets on the surface of Moringa oleifera leaves, greatly shorten the drying time, and improve the subsequent processing efficiency of Moringa oleifera leaves. The Moringa Leaf Air Dryer is specially designed for multiple turning and conveying, fully removing the moisture on the surface of the Moringa Leaf. The equipment adopts frequency conversion conveying, the speed is adjustable, and the conveying is stable.

Moringa leaf cutter: Moringa leaves are cut into sections with uniform length, the speed of the conveyor belt is adjusted by the frequency converter, and the length of the cut sections can be adjusted as required. One machine is multi-purpose, high output, easy to replace the cutter head, easy to operate and easy to clean.

Multi-layer belt moringa leaf dryer: The dryer is the key equipment, which determines the effect and quality of moringa leaf after processing. Using our mesh belt type moringa leaf dryer, with an intelligent control system, can make moringa leaf The drying is always maintained in a reasonable drying environment to ensure the effect of the finished product. This moringa leaf dryer has the advantages of large processing output, high degree of automation, controllable drying effect and quality, and adjustable drying time. Flexible heat source selection: Coal, wood chips, natural gas, diesel, propane, electricity, etc.

Moringa leaf powder making machine: Grind the dried Moringa leaves to a fineness of 10-120 mesh, and obtain the particle size of Moringa powder by selecting screens with different apertures. Moringa leaf grinder has simple structure, stable operation, low noise and good crushing effect. Air-cooled or water-cooled, it can work continuously for a long time.

Moringa leaf powder packing machine:The moringa leaf powder packaging machine adopts PLC control system, which is intelligent and controllable, and can be quickly adjusted according to customer packaging requirements. Packaging weight and quantity are automatically adjusted. It can automatically complete the tasks of moringa powder measurement and filling, with high precision, small error, intelligent bag delivery, adjustment of bag width, and filling of moringa powder. It is suitable for all kinds of fine powders with good fluidity.

Moringa leaf processing machien advantages

1. Can be customized. Configure different production lines according to customer output requirements.The moringa leaf production line is fully automatic and semi-automatic, and customers can choose according to their own needs.

2. Easy to operate. The moringa leaf production line is easy to install and can be used after connecting to the power supply. It is reliable to use and easy to disassemble.

3. Moringa leaf is of high quality. The dryer adopts medium and low temperature drying. After drying, the original color and nutrients of moringa leaf can be completely retained. The equipment is made of stainless steel, in line with food machinery standards.

4. Flexible heat source selection of dryer: coal, wood chips, natural gas, diesel, propane, electricity etc.

5. Wide range of applications. Most of the machines in the line are not only suitable for moringa leaf, but also for other fruits and vegetables.

1000kg/h Moringa Leaf Processing Machine Parameter And Moringa Leaf Processing Machine Price:

| 1000kg/h moringa leaf processing line | |||||

| Number | Name | Power | Size | Output | Price(Dollar) |

| 1 | Moringa Leaf Washing Machine | 3.37KW | 3000*1020*1350mm | 1000kg/h | 5000 |

| 2 | Moringa Leaf Air Dryer | 6KW | 4000*950*1600mm | 1000kg/h | 6000 |

| 3 | Moringa Leaf Cutter | 1.1KW | 1180x550x1020mm | 500kg/h | 1100 |

| 4 | Moringa Leaf Dryer | 33.12KW | 12000*2000*2500mm | 1000kg/h | 42000-63000 |

| 5 | Moringa Leaf Grinder | 5.5KW | 750*600*1260mm | 200kg/h | 3000 |

| 6 | Moringa Leaf Powder Packaging Machine | 3.5KW | 3000*1500*2600mm | 30-60 packs/min | 12000 |

| The moringa leaf processing line can be equipped according to the user's requirement and the production demands. | 69100-90100 | ||||

200-300kg/h Moringa Leaf Processing Machine Parameter And Moringa Leaf Processing Machine Price:

| 200-300kg/h moringa leaf processing line | |||||

| Number | Name | Power | Size | Output | Price(Dollar) |

| 1 | Moringa Leaf Washing Machine | 1.87KW | 2500*1300*1400mm | 200-500kg/h | 4500 |

| 2 | Moringa Leaf Cutter | 1.1KW | 1180x550x1020mm | 500kg/h | 1100 |

| 3 | Moringa Leaf Dryer | 3KW | 2100*930*2100mm | 200-300kg/h | 7000 |

| 4 | Moringa Leaf Grinder | 5.5KW | 750*600*1260mm | 30-150kg/h | 2000 |

| 5 | Moringa Leaf Powder Packaging Machine | 1.6KW | 700*750*1650mm | 30-60 packs/min | 8000 |

| The moringa leaf processing line can be equipped according to the user's requirement and the production demands. | 22600 | ||||

Moringa Leaf Processing Machine Video:

Previous post:

Next post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.