-

Dehydrate Moringa Seed in a Dehydrator/Moringa Seed Drying Process

2021-07-17Moringa Seed Dryer: After picking, the Moringa seeds are loaded into the material tray. The 6p drying and dehumidification integrated host is equipped with a 10 cm polyurethane drying room of 5.5 meters long, 3 meters wide and 2.2 meters high...Learn More -

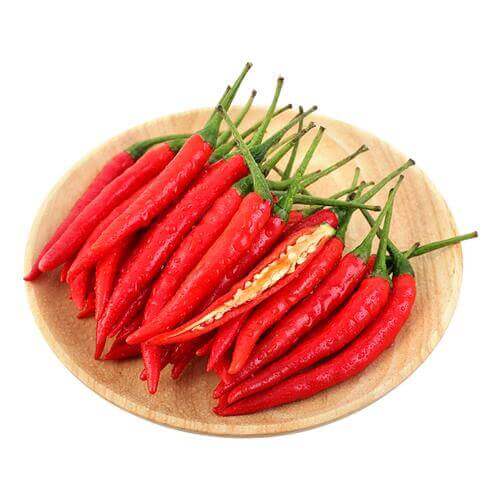

Dehydrate Pepper in a Dehydrator/Pepper Drying Process

2021-07-17Pepper Dryer: Due to the different quality and maturity of pepper, the unsuitable pepper should be selected before drying. When feeding, the pepper should be evenly laid with a thickness of about 5cm...Learn More -

Dehydrate Balsam Pear in a Dehydrator/Balsam Pear Drying Process

2021-07-17Balsam Pear Dryer: The initial moisture content of balsam pear is about 90%, and the moisture content of dried balsam pear slices is about 13%. The drying temperature of Momordica charantia L. is suitable for middle and high temperature...Learn More -

How to Dry Tobacco Leaf/Dehydrate Tobacco Leaf in a Dehydrator

2021-07-16To dry tobacco on a large scale, traditional methods cannot meet the demand, so drying with a dryer is a good choice. The powerful Baixin tobacco leaf drying machine is accessible with distinct capacities and the drying system can be fully customized according to your requirements...Learn More -

Dehydrate Candied jujube in a Dehydrator/Candied jujube Drying Process

2021-07-16Candied jujube Dryer: The raw material was dried at (60 ± 2) ℃ for about 12 hours. The temperature was kept at 55 ℃ - 65 ℃ in the first 4 hours, 65 ℃ - 70 ℃ in the middle 5 hours, and then dropped to 65 ℃ in the last 4 hours...Learn More -

How to Dry Konjac/Dehydrate Konjac in a Dehydrator

2021-07-16The natural drying method of drying dried konjac chips by sun exposure is the main way of traditional dry chip production. However, the long rainy weather and poor threshing ground conditions have a great impact on the quality of dried konjac chips,Henan Baixin has two types of professional konjac dryer...Learn More -

Dehydrate Pitaya in a Dehydrator/Pitaya Drying Process

2021-07-16Pitaya Dryer: Put the soaked pitaya chips on the plate, put them on the material truck, and push them into the drying room until the syrup on the surface of the chips is no longer sticky. Set the temperature and humidity parameters of the dryer...Learn More -

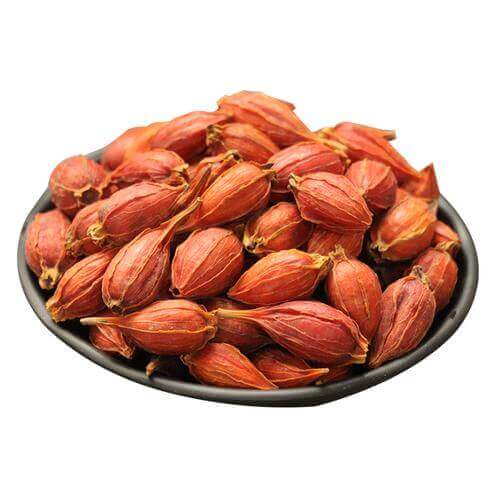

Dehydrate Yellow gardenia in a Dehydrator/Yellow gardenia Drying Process

2021-07-16Yellow gardenia Dryer: The drying process of Yellow gardenias is relatively simple, it only needs three steps to complete, the first step of system setting, the temperature is set at 55 ℃, the drying mode does not dehumidify for 1.5 hours...Learn More -

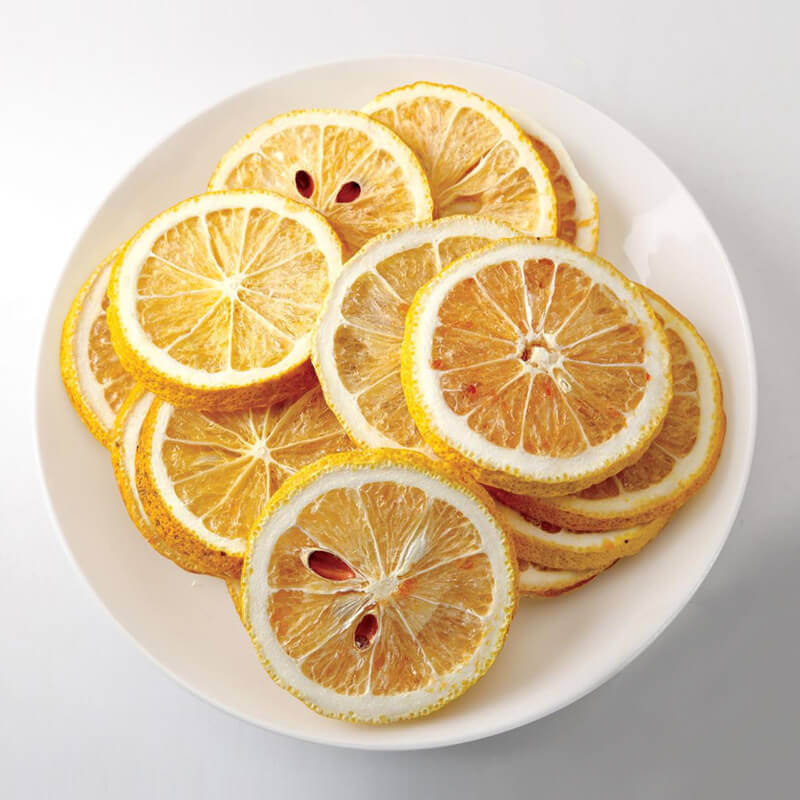

How to Dry Lemon/Dehydrate Lemon in a Dehydrator

2021-07-16If eating a small number of lemon slices at home, you can make them in the sun and the oven. But if you need to mass-produce and sell lemon slices, using a dehydrator to make dried lemons is a good choice.Henan Baixin has two ways to dry lemon in large quantities...Learn More -

Dehydrate Okra in a Dehydrator/Okra Drying Process

2021-07-16Okra Dryer: The moisture content of okra is relatively high, the moisture content reaches 80%, so the drying time is relatively long, and the drying process should control the temperature, otherwise the effect of beautiful hue will not be achieved...Learn More -

Dehydrate Cucumber in a Dehydrator/Cucumber Drying Process

2021-07-16Cucumber Dryer: The general 7p drying and dehumidification system is equipped with a 10 cm polyurethane thermal insulation room with 5.8 meters long, 3 meters wide and 2.2 meters high. The thermal conductivity of this kind of thermal insulation room is low...Learn More -

Dehydrate Exocarpium in a Dehydrator/Exocarpium Drying Process

2021-07-16Exocarpium Dryer: The thickness of each layer is controlled in 2-3 cm (after slicing), and each material car is placed 12-14 layers. The drying temperature is controlled in 55℃ -- 60℃, and the drying time is about 30-36 hours...Learn More

-

Continuous Mesh belt dryerVegetable Mesh Belt Dryer/Drying Machine Hemp Mesh Belt Dryer/Drying Machine Ginger Mesh Belt Dryer/Drying MachineCabbage Mesh Belt Dryer/Drying Machine Radish Mesh Belt Dryer/Drying Machine Spice Mesh Belt Dryer/Drying Machine Garlic Mesh Belt Dryer/Drying Machine Onion Mesh Belt Dryer/Drying Machine Cassava Mesh Belt Dryer/Drying Machine Konjac Mesh Belt Dryer/Drying MachineHeat pump dryerHousehold Fruit Dryer/Drying MachineCommercial Fruit Dryer/Drying MachineHousehold Vegetable Dryer/Drying MachineAll-In-One Universal Dryer Without InstallationTomato Heat Pump Dryer/Drying MachineMango Heat Pump Dryer/Drying MachinePineapple Heat Pump Dryer/Drying MachineMushroom Heat Pump Dryer/Drying MachineBeef Heat Pump Dryer/Drying MachineTobacco Leaf Heat Pump Dryer/Drying MachineFruit and vegetable processing machineBubble Washing MachineSemi-automatic Banana Chips Production LineFull Automatic Banana Chips Production LineSemi-automatic French Fries Production LineFull Automatic Frozen French Fries Production LineFull Automatic Potato Chips Production LineSemi-Automatic Potato Chips Production LineLarge Output Garlic Powder Processing LineSupport Customization Garlic Processing LineLarge Output Onion Powder Processing Line