How to Make Dry Meat

How to Make Dry Meat

Dried meat products, also known as meat dehydrated products, are a type of cooked meat made from pre-processed meat by natural or artificial methods to remove a certain amount of water from the meat and reduce its water activity to a level that is difficult for microorganisms to use. product. The dehydration and drying of perishable food such as meat is not only a storage method, but also a processing method. Vitality is inhibited, so as to achieve the purpose of processing novel products or prolonging storage time. So if we want to make processed meat products or dry meat, how to make dry meat? Next, I will share with you the methods ohow to make dry meat.

The production method of jerky varies slightly due to different regions or raw materials, but the basic procedure is the same. Cooking→slicing→adding seasonings for dipping→drying to make mature meat products, the latter procedure is meat selection→cutting→air drying→adding seasonings to bake mature meat products. This article introduces the production steps of jerky and the selection of meat products dryer.

The process of dryer Meat at Home

1. Raw material selection

Fresh meat with firm, lean meat is preferred. If it is frozen meat quality, it needs to be defrosted in the defrosting room. After the beef is thawed, it can be used until the color and quality return to normal.

2. Cutting

Cut the selected buttocks and hind legs into the required shapes (sheets, strips), when the output is large, you can choose the cutting equipment to complete, the cut beef is more uniform, and it is easy to hang the material when drying.

3. Seasoning

According to taste requirements, add various seasonings for marinating, such as salt, soy sauce, sugar, five-spice powder, chili powder, etc. The marinating seasonings should be stirred evenly to ensure full flavor. The pickling temperature is maintained at 0°C to 4°C. (According to different tastes, it can be matched with different seasonings to make five-spice, salty and dry, original, etc.)

4. Drying

Hang the meat strips in the drying room for drying or select the smart drying mode in the new heat pump beef jerky drying room. Note: The meat strips should not drip, and should be hung upright without sticking to each other. Keep a little distance between the meat strips to facilitate ventilation and even drying. Generally, in an indoor environment with a temperature of 40 ° C and a temperature of about 60%, a batch can be dried in 36 hours. At this time, it can be seen that the beef is dark red in color, and feels dry and slightly hard when you pinch it.

If you are drying a lot of meat then the above drying method is not suitable and you will need to use a meat dryer.

After hanging or putting the meat strips in the dryer, start the dryer and set the parameters. Note: The meat strips should not drip, hang up straight, do not stick to each other, and keep a little distance between the meat strips to facilitate ventilation and dry evenly.

This is a relatively common drying process for dried meat. Of course, some of them will have different production processes due to different special requirements. And after learning how to dry meat at home, let's learn more about the meat dryer. Meat dryer machine are divided into three types: meat dryer room, all-in-one meat dryer machine and mesh belt meat dryer.

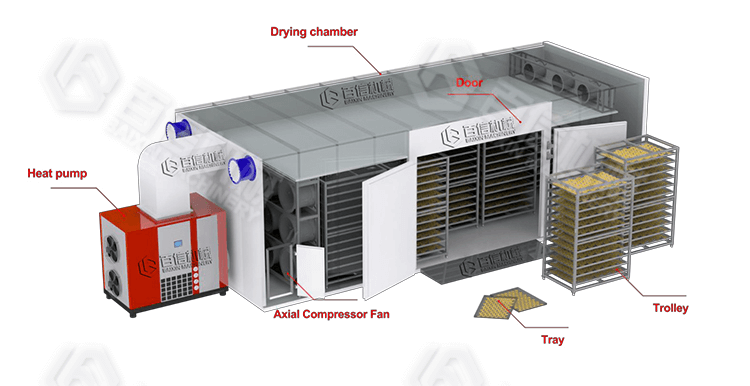

1. Meat dryer room

The first type of dryer is the meat dryer room. The meat dryer room is equipped with a trolley with trays and tray racks. When we dry the meats, we put the meats in the tray, on the tray rack of the cart, and push it into the meat drying chamber to dry. Meats are putted on the shelf car and enter the closed cycle drying room for drying without any pollution in the process. The heat source of the meat dryer room is air. The heat in the air is absorbed by the heat pump compressor. After being compressed and released, a large amount of high-temperature hot air can be obtained, so as to achieve uniform drying and processing of meats.

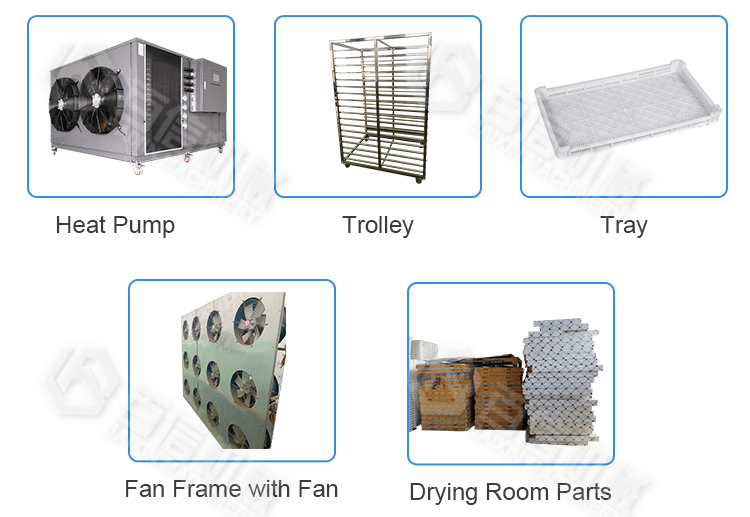

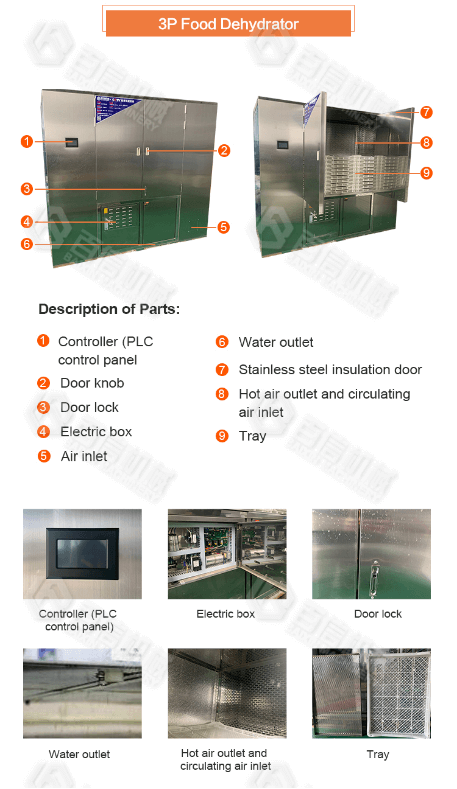

Components of meat dryer room

One set meat dryer room contains: heat pump dryer host, dryer chamber, fan frame with fan, trolley with tray. The dryer chamber is used 100mm polyurethane insulation board, supporting 304 stainless steel trolleys and trays. The main structure of the meat dryer room is divided into: heat pump drying dehumidifier, drying room, hot air circulation system, dehumidification system, automatic intelligent control system, and high-efficiency waste heat recovery dehumidification device.

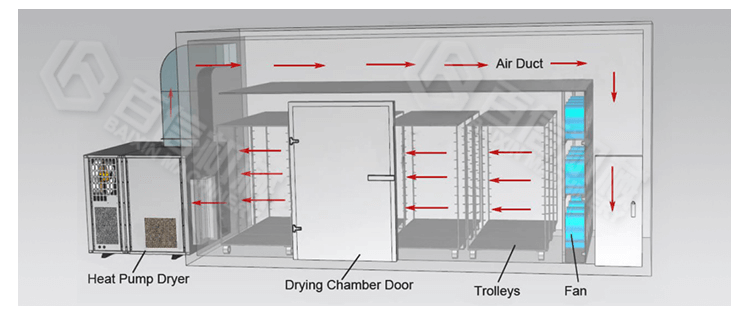

The working principle of meat dryer room

The meat heat pump dryer uses the reverse Carnot principle to let the hot air circulating blower dry the vegatable. Heat Pump Dryer Compressor Heat Exchanger Blocked Radiator (External to Machine). Compressor and other equipment make up the refrigerant circulation system. The fan impeller rotates, the outside air enters the oven, passes through the heater, forms hot air, and then enters the studio through the gap of the air distribution plate, and a large amount of hot air in the circulating flow continues to enter the new air inlet for supplementation. The moisture discharged after recovery is discharged from the exhaust port. The whole cycle makes the vegatable heated evenly and achieves the purpose of drying.

Technical parameters of meat dryer room

| heat pump dehydration room list | ||||||||||

| type | machine size(MM) | Capacity (KG) | power | Qty of fan | fan power | total power(kw) | Qty of cart | Qty of tray | cart size(MM) | tray size(MM) |

| 3P A | 3500×2200×2200 | 200-400 | 2.25 | 6 | 0.25/pc | 3.75 | 6 | 78 | 670×810 | 600×800 |

| 8P A | 5300×2200×2800 | 450-750 | 6 | 12 | 0.37/pc | 10.44 | 6 | 156 | 1210×870 | 600×800 |

| 15P | 7500×3000×2800 | 900-1500 | 11.25 | 12 | 0.55/pc | 17.85 | 12 | 312 | 1210×870 | 600×800 |

| 1P D | 1180×680×1800 | 50-80 | 1 | — | — | 1 | — | 15 | — | 600×800 |

| 3P D | 2100×930×2100 | 120-300 | 3.5 | — | — | 3.5 | — | 40/60 | — | 600×800 |

| 8P D | 4000×1960×2050 | 650-1000 | 8 | — | — | 8 | 8 | 232 | 600×800 | 600×800 |

| The drying machine can be equipped according to the user's requirement and the production demands. | ||||||||||

Advantages of meat dryer room

1 Wide application. Suitable for vegetable, fruit, seafood, spice etc different kinds of material.2 High drying capacity. Each hour can drying 3-4kg water.

3 Better drying effect. Can better keep material shape , color , nutrition etc.

4 Simple operating. PLC touch screen control panel , can set up temperature, humidity in advance

5 Low energy consumption. Heat pump system, can save 70% energy.

Other application areas of meat dryer room

Heat pumps dryer can be used in many applications, in addition to drying meats can also be used in agriculture, industry, seafood, grain, herbal medicine, construction, paper products, condiments, mineral industry, etc.1. Dried meats such as radish, lettuce, pumpkin, carrot, spinach, cassava, etc.

2. Fruits such as apples, lemons, mango slices, dried longan, dried longan, etc.

3. Dried meat such as sausage, beef, duck, ham, etc.

4. Others it can dry noodles/wooden/incense/herbs/floss etc.

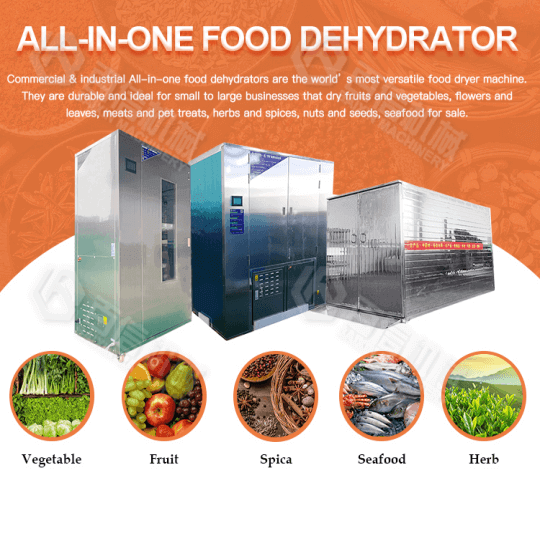

2. All-in-one meat dryer machine

The another one is the all-in-one meat dryer machine. The drying principle is the same as that of the meat dryer room. The all-in-one meat dryer machine is equipped with a cart with trays and tray racks. When drying meats, we put them in trays, put them on the tray racks of the cart, and then push them into the meat drying chamber for drying.The heat source of the meat integrated dryer is air energy. The heat in the air is absorbed by the heat pump compressor. After compression and release, a large amount of high-temperature hot air can be obtained, so as to achieve continuous and uniform drying and processing of meats. The operation of this all-in-one drying unit is relatively simple, simply plug in and dry.

Components of all-in-one meat dryer machine

One set all-in-one meat dryer machine contains: power jack, water outlet,exhaust air outlet, supporting wheels, PLC controller pancl, door lock, observation window,circulating air inlet, outlet for hot and dry air, PP tray, stainless steel tray, supporting racks for trys. The meat all-in-one machine has compact structure, good energy-saving effect, wide application range, high drying quality, convenient operation, simple installation and disassembly. It is the best drying equipment for small businesses, drying experiments and scientific research. The user only needs to connect the power to use, it is the easiest to operate meat dryer.

Technical parameters of all-in-one meat dryer machine

| All-in-one food dehydrator machine list | ||||||||

| type | machine size(MM) | Capacity (KG) | power | total power(kw) | Qty of cart | Qty of tray | cart size(MM) | tray size(MM) |

| 1P | 1180×680×1800 | 50-80 | 1 | 1 | — | 15 | — | 600×800 |

| 3P | 2100×930×2100 | 120-300 | 3.5 | 3.5 | — | 40/60 | — | 600×800 |

| 8P | 4000×1960×2050 | 650-1000 | 8 | 8 | 8 | 232 | 600×800 | 600×800 |

| The drying machine can be equipped according to the user's requirement and the production demands. | ||||||||

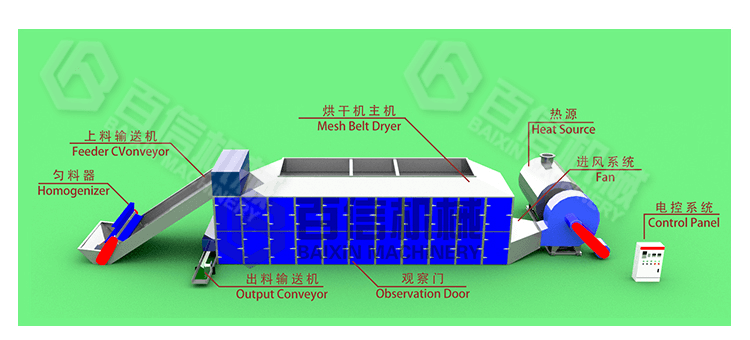

3. continuous mesh belt meat dryer

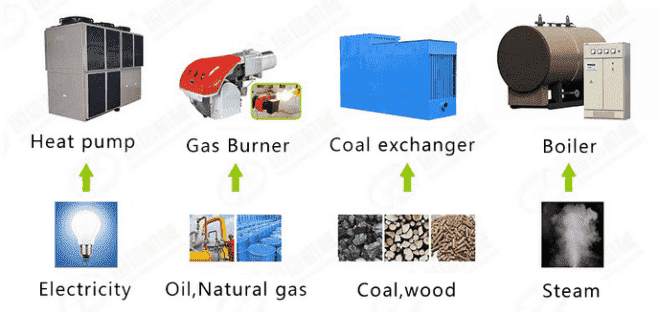

And then let's take a look at the continuous mesh belt meat dryer with the largest output. Mesh belt meat dryer have a wide range of heat sources such as coal heating, gas heating, steam heating, biomass pellet heating or electric heating. It is a multi-layer continuous drying structure. When drying meats, just put the meats in the feeding port, and the meats will enter the dryer with the feeding conveyor for drying.Meats are dried and dehydrated layer by layer from top to bottom. The drying speed is fast and the production efficiency is high, which is very suitable for the drying and processing of large quantities of meats.

Components of continuous mesh belt meat dryer

One set continuous mesh belt meat dryer contains: homogenizer, feeding conveyor,dryer host, output conveyor, observation door, heat source, air intake system, control panel. The meat dryer consists of 4 parts, namely the feed conveyor, the main machine of the mesh belt meat dryer, the heat source and the discharge conveyor. The reformer provides heat, and the through-flow mesh belt meat dryer is the main body of the drying equipment, which consists of a cabinet and multi-layer conveyor belts; the electrical control system controls the start, operation and stop of the entire equipment. With the cooperation of other auxiliary components, the drying equipment completes the drying and discharging process of food, and realizes the drying process of food drying.

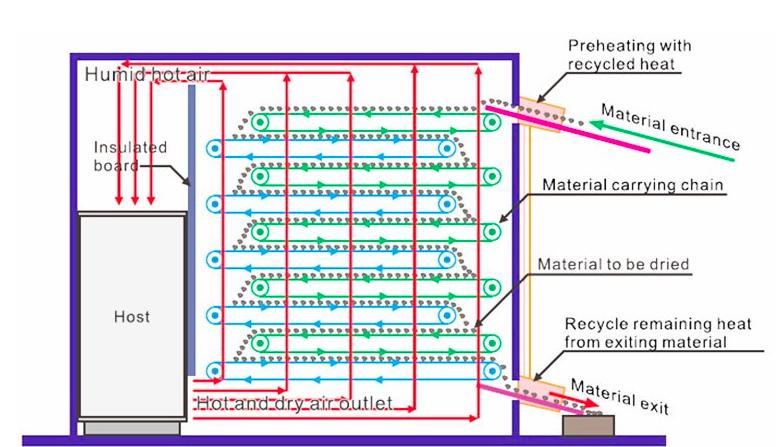

The working principle of continuous mesh belt meat dryer

Baixin continuous mesh belt meat dryer is a continuous production drying equipment. The main heating methods are electric heating, steam heating and hot air heating. Its main working principle is to distribute the material evenly in the network. Through the operation of the machine, the meat moves in the dryer, and the hot air extracts the water vapor of the meat. So as to achieve the purpose of drying. The working temperature is 40-120 degrees Celsius. The drying cycle is 1-5 hours. Mainly used for agricultural and sideline products such as fruits and meats, Chinese herbal medicines, etc. The equipment is easy to operate, saves time, has a healthy drying process, and protects the environment.

Technical parameters of mesh belt meat dryer

| continuous mesh belt dryer list | |||||||

| Model | operation temperature | drying time | thickness of the material | the size of motor | capacity | heat source | total power |

| BX-2*6M | 40-120℃ | 0.5-5h | 50-200mm | 6*2*2.5 | 200-400kg/h | electricity | 66.5kw |

| natural gas/propane | 12.22kw | ||||||

| coal/wood chips | 13.72kw | ||||||

| steam | 11.22kw | ||||||

| BX-2*9M | 9*2*2.5 | 500-800kg/h | electricity | 79.76kw | |||

| natural gas/propane | 20.12kw | ||||||

| coal/wood chips | 23.12kw | ||||||

| steam | 16.62kw | ||||||

| BX-2*12M | 12*2*2.5 | 1000-1500kg/h | electricity | 153.12kw | |||

| natural gas/propane | 33.12kw | ||||||

| coal/wood chips | 36.12kw | ||||||

| steam | 25.62kw | ||||||

| door in Color steel,baffle in Galvanized,the main frame in Carbon steel. | |||||||

The above are the three meat dryer machines we commonly use. At the same time, our company also produces microwave meat dryer machines. If you are interested in meat dryer machines or want to know more about meat dryer machines, please feel free to contact us.

Hot air food dryer video:

Previous post:

Next post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.