How to Make Dry Ginger/How to Dry Ginger/Dry Ginger Making Process

How to make dry ginger/how to dry ginger/dry ginger making process

Ginger is generally distributed in subtropical areas, which is rich in a variety of nutrients. Ginger products are very popular in the world, especially in Southeast Asia, which can create a lot of foreign exchange for the country every year. In order to make full use of ginger resources, drying can not only make full use of ginger, but also obtain higher value-added effect.

Thus, the drying process of ginger is extremely important. How to make dried ginger? There are two ways to make dried ginger. One is to use the sun to dry in the traditional way, and the other is to use professional machinery to dry. Next, I will introduce two ways to dry ginger.

In a traditional way: sun drying of ginger:

Step 1. wash the ginger and select the ones with poor quality during the washing process.

Step 2. then cut the gingers and place them evenly on the tray. Do not stack them too much to affect the drying effect.

Step 3. dry them in the sun for 2-3 days.

This traditional method of drying ginger is economical and does not require any investment. However, because the drying effect is greatly affected by the environment and is not easy to control, the drying color of ginger is uneven, and even defective ginger may appear. During the drying process of ginger, a certain amount of manual turnover is required.

Therefore, most ginger product manufacturers use the second processing method.

In a professional mechanical way: drying and processing of ginger:

This drying method is to use ginger drying equipment to carry out reasonable dehydration of ginger. It can not only solve the shortcomings of the traditional method of drying ginger, but also improve the yield and increase the efficiency of drying ginger. At present, ginger drying room and mesh belt ginger dryer are widely used. Let me introduce to you the usage and drying principle of the two machine.

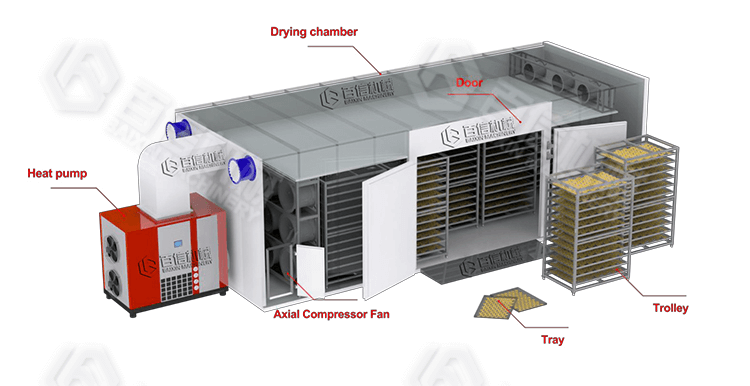

Heat pump dryer

Step 1. wash the ginger and select the ones with poor quality during the washing process.

Step 2. then cut the gingers and place them evenly on the tray. Do not stack them too much to affect the drying effect.

Step 3. push the cart into the drying room to dry for 8 hours.

If we use the ginger drying oven, the equipment is equipped with a small cart with a tray and a tray rack. The heat source of the ginger drying room is air. The heat in the air is absorbed by the heat pump compressor. After compression and release, a large amount of high-temperature hot air can be obtained, so as to realize the continuous and uniform drying and processing of ginger.

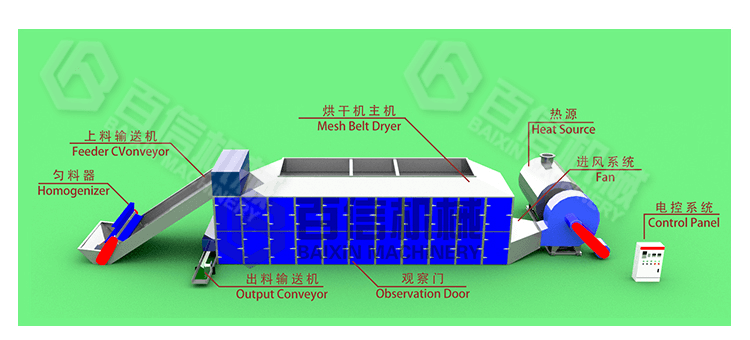

Mesh belt dryer

Step 1. wash the ginger and select the ones with poor quality during the washing process.Step 2. then cut the gingers and place them evenly on the tray. Do not stack them too much to affect the drying effect.

Step 3. put the ginger slices at the feeding port, and the ginger slices will enter the dryer with the feeding conveyor for drying.

If we are using a mesh belt type ginger dryer, then this equipment has a wide range of heat sources, such as coal heating, gas heating, steam heating, biomass pellet heating, or electric heating. It is a multi-layer continuous drying structure. The gingers are dried and dehydrated layer by layer from top to bottom. The drying speed is fast and the production efficiency is high. It is very suitable for the drying and processing of large quantities of gingers.

Having learned about the above two kinds of dryers, let me introduce you how to choose a dryer suitable for you.

How to choose a suitable ginger dryer

First of all, it depends on our demand for ginger processing. For large output, use a ginger mesh belt dryer. Generally, the output of a ginger mesh belt dryer is 300-2000kg/h. For small output, the output of a heat pump dryer is 100-5000kg/batch. Oven length and mesh belt layers can be customized. We can choose and match them reasonably according to our own processing requirements.Ginger drying process is becoming more and more popular in the world, and ginger drying also has bright prospects. Do you want to start a ginger business? If you want to know more professional questions about ginger drying, please feel free to contact us online!

Ginger making process video:

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.