How to Make Dried Shitake Mushrooms

How to make dried shitake mushrooms and process steps?

Mushrooms are widely distributed throughout the earth and are abundant in forest deciduous areas. Edible mushrooms are ideal natural foods or multifunctional foods. So far, the most edible mushroom in the world, the scientific name is Agaricus bisporus, commonly known as shitake mushroom. There are many kinds of shitake mushrooms but most shitake mushrooms have a very short fresh-keeping time.

The traditional ways to dry shitake mushrooms?

Because fresh shiitake mushrooms are not conducive to preservation, when shiitake mushrooms are mature, mushroom farmers will make shiitake mushrooms into dried shiitake mushrooms. In the past, there were two main methods of making dried shiitake mushrooms: first, drying in the sun; second, drying with equipment, such as coal-fired hot-blast stoves. The former is affected by the weather seriously. When it comes to rainy days, the mushrooms will not be dried in the sun, but the mushrooms may become moldy and deteriorated. The fragrance of natural drying is not very strong, and the gills are whitish. The latter has serious environmental pollution and still has certain safety hazards, which may cause accidents such as fires and explosions.Under such circumstances, more and more mushroom farmers hope to have more efficient, energy-saving, safe, and stable drying equipment that can replace the original old drying equipment. In response to this demand from mushroom farmers, Henan Baixin drying equipment manufacturer produces an air-energy dryer after several years of research and development and repeated field tests.

What is shitake mushrooms drying machine?

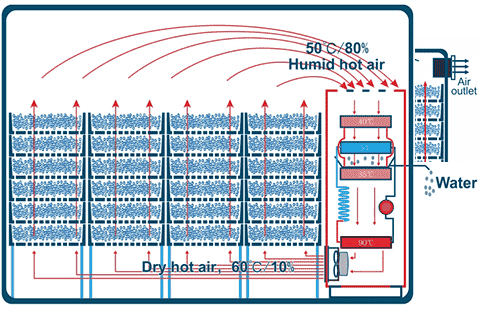

The air energy dryer is a new type of dryer that uses an air energy heat pump as the host. During the drying process, only a small amount of electricity is needed to absorb a large amount of free heat from the surrounding environment, and then the free heat is heated. It is compressed into high-temperature heat energy and transported to the drying room to dry the mushrooms. The dried gills are beige and have a strong fragrance.Baixin Food Dehydrator has a compact structure, great energy-saving, wide application, high drying quality, easy operation, simple installation and removable. it is the best drying equipment for small firms, drying experiment and scientific research. The users only connect the power to use, is the easiest operation heat pump dryer.

The process steps for drying shitake mushrooms

In the process of mushroom drying, there are usually the following steps:- Preparation of fresh shitake mushrooms, preferably fresh mushrooms that have just been picked. The mushrooms must be dried within 6 hours after harvest. If refrigerated conditions are available, the storage time can be extended appropriately. If it mushrooms in the freezer, it is best to first Leave it in the open air for 1-2 hours to let the temperature of the mushrooms approach the air temperature gradually, which also saves the heat of warming up after the mushrooms enter the drying room in the early stage.

- The mushrooms should be placed on the material basket or trays. The material can be made of bamboo or 304 material or Food-grade PVC. Place the mushrooms according to the category of mushrooms. Pay attention to the number not too large, too dense, and need to have appropriate gaps, so that the hot air of the axial flow fan can blow across the surface of all materials smoothly. The greater the surface area of the hot air blowing through the mushrooms and the faster the wind speed, the higher the drying efficiency of the material, and the relative drying time will be reduced. On the contrary, if the material to be dried is too much, too dense, and the wind cannot be blown through, the overall drying time and effect will be reduced.

- During the drying process, pay attention to observe the humidity in the drying room during the first few hours. Mushrooms are high-humidity materials. Once the moisture is evaporated, the humidity in the drying room will increase rapidly. The period is the stage of constant temperature and color fixing of the shitake mushrooms. The moisture in the drying room must be drained in time, otherwise, the shitake mushrooms will be blistered and discolored in such an environment for a long time, which will ultimately affect the quality of the dried shitake mushrooms.

- The drying time for a shitake mushroom dryer to dry a batch of mushrooms is usually a combination of several aspects, such as the drying capacity of the mushrooms, the moisture content, the drying dehydration capacity, the heat of the main mechanism, the number of fans, the power, and the volume of the drying room. So we usually say that it takes 20 hours to dry a batch of mushrooms, which is inaccurate actually because the result of the drying time is the result of a combination of the above factors. Once the above variables change, the final result is different definitely.

Shitake Mushrooms dehydrator video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.