How to Make Dried Onions

How to make dried onions:

Onions are rich in nutrients. They are rich in nutrients such as potassium, vitamin C, folic acid, zinc, selenium, and fiber. They can also prevent cancer and help digestion. They are well-loved by the public. To avoid onion rot, people usually dry the onions and store them directly. If you need to dry the onions in large quantities, you need to slice the onions and then use a dryer to dry them. Next, I will share with you the specific steps of drying onions.

Air-dried onions:

- 1.Harvesting, dry the onions in a warm, dry, well-ventilated location, such as a shed or garage. Spread out the onions in a single layer on a clean, dry surface. Dry the onions for two to three weeks until the onion tops and necks are thoroughly dry and the outer bulb scales begin to rustle.

- 2.After the onions are properly dried, cut off the tops about one inch above the bulbs, discard any that show signs of decay. An alternate preparation method is to leave the onion tops untrimmed and braid the dry foliage together.

- 3.Place the dried onions in a mesh bag, old nylon stocking, wire basket, or crate. The storage container must allow air to circulate through the onions. Store the onions in a cool, moderately dry location. Storage temperatures should be 32 to 40 degrees Fahrenheit. The relative humidity should be 65 to 70 percent. Possible storage locations include a basement, cellar, or garage. Hang the braided onions from a rafter or ceiling. If storing the onions in an unheated garage, move the onions to an alternate storage site before temperatures drop below 32 degrees Fahrenheit.

How to make dried onions in large quantities:

1. Slice and rinse.Use a knife to cut off the onion shoots of the mature onion, dig out the roots, peel off the old skin and scales, and trim off the damaged parts. Separate the onions by size and rinse them in clean water once. Use BX-1 type onion directional slicer to cut horizontally into ring-shaped slices of different diameters, the width of onion slices is 4~4.5mm. Rinse with water while cutting, and shake apart the overlapping onion slices. Rinse after slicing. When rinsing, put the onion slices in a bamboo basket or a perforated plastic basket, and place them in a clear water sink. Use a colander to turn the onion slices up and down. Generally, rinse with water for 3 times.

2. Shake water and dry.

Use a centrifugal dryer to dry the onion. Spread a layer of clean gauze in the centrifuge tank, and then load the onion slices at 1300 rpm. After centrifugation for 30 seconds, take out the gauze together with the onion slices and spread. On the drying sieve, the mesh holes are generally 3mm×3mm or 5mm×5mm, and then the drying sieve is installed on the drying carriage frame. Before feeding the dryer, preheat the temperature up to 60℃, and control the drying temperature at 58~60℃ for 6~7 hours. When the moisture content drops below 5%, a single tunnel or hot air dryer 24 300~400kg dehydrated onion slices can be produced within an hour. Generally 13 to 15 tons of raw materials can produce 1 ton of dry products.

3.Select

First move the dried onion slices into the sorting machine to remove the debris and impurities, and then sort out the unqualified onion slices and impurities on the conveyor belt to remove the metal inclusions. Then pour the onion slices on a stainless steel platen or a non-toxic white plastic plate and carefully select them, and put them into double-layer plastic edible bags according to the quality standards.

Baixin Machinery’s most popular onion dryers are heat pump dryers and continuous mesh belt dryers.I would be happy to introduce these two dryers in detail for you:

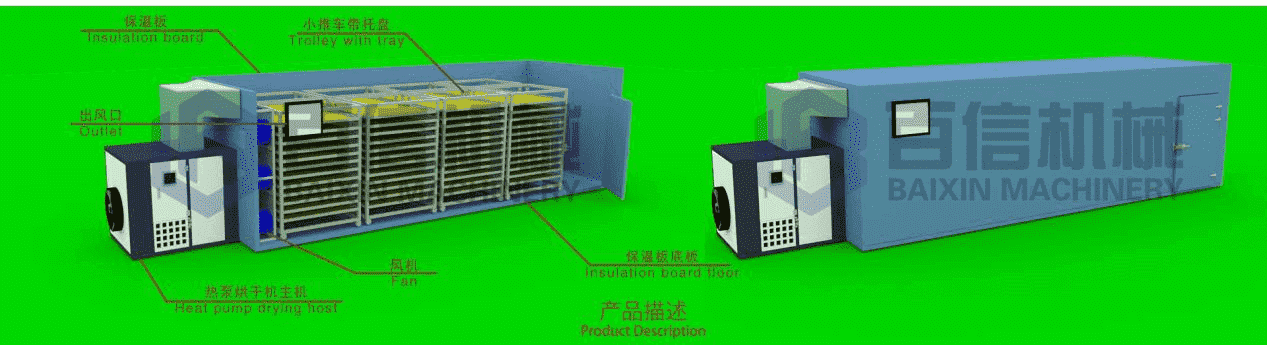

1:The first method: onion heat pump dryer

Commercial 100-3000kg/h large amount of dehydration wide application and easy operationHeat pump drying machine use the principle of inverse Carnot cycle. It absorbs low-temperature heat energy in the air, which becomes high-temperature heat energy after efficient heat collection and integration by the heat pump system, and is transported to the drying room for cyclic heating and drying of materials.It refers to exhausting the hot and humid air in the drying room directly to the outside of the drying room through dehumidification device, and then replenishing natural fresh air.

Hot air circle drying machine belongs to high temperature heat pump unit. Its working principle is: the working fluid of the heat pump is compressed by the compressor, becomes high temperature and high pressure gas, enters the condenser, condenses and liquefies the heat, and is used for air heating in the drying room. The moisture in the material is vaporized and evaporated by the form of hot air, and the evaporated water vapor is discharged by the moisture discharge system, thereby achieving the purpose of drying the drying material.

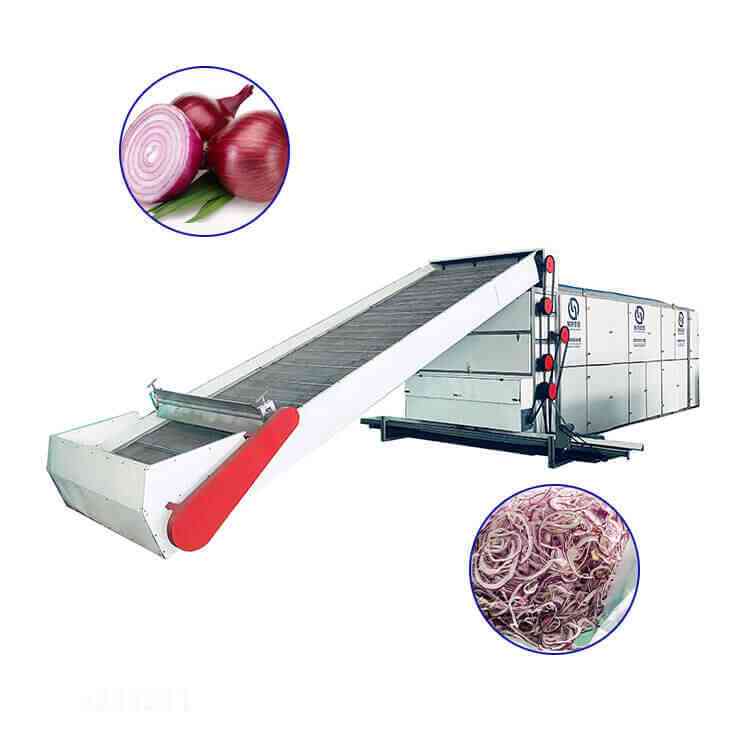

2:The second method: onion continuous mesh belt drying machine

Large amount of dehydration 200-5000kg/h onion drying machine continuous automatic work easy operationOnion dryer machine is a kind of continuous production drying equipment, the main heating way has electric heating, steam heating, hot air heating. Its main working principle is to spread the material evenly in the network. The material is moved in the dryer by the operation of the machine, and the hot air draws out the water vapor of the material. so as to achieve the purpose of drying.

The operation temperature is 40-120 degree centigrade. And the dry cycle is 1-5 hours.

Onion drying video:

Previous post:

Next post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.