How to Make Copra/Dehydrated Copra

The function of dried copra:

Coconut is a kind of fruit that grows in tropical regions and is a plant fruit of the genus Coconut in the palm family. In foreign countries, coconut trees are called "trees of life" and coconuts are also called "fruit of life". Its juice, meat has edible nutritional value. Copra: The endosperm of coconut, also known as coconut flesh. After taking coconut milk, smash the outer peel to get it. Coconut meat contains protein and carbohydrates. It can be made into copra, coconut milk powder, coconut protein, coconut milk, coconut paste, and colorless coconut oil.Drying the pulp of coconut is called dried coconut, that is copra which has the following effects: the first one can supplement sugar for the human body; the second one, the various vitamins contained in dried coconut can promote the body's metabolism, which is mainly suitable for patients with rough skin; the third one is making colorless coconut oil.

Traditional Drying Method for copra:

There are three ways to dry copra out:- Bake dry in the oven or microwave. [The advantage is that it is quick and convenient, the disadvantage is that it is easy to bake]

- Stir-fry in an iron pan. [The advantage is that some people watch it and not easy to fry burnt, but the disadvantage is that it is not as easy as an oven]

- Dry in the sun. [The advantage is that it is convenient and energy-saving, and it will never be smeared, but the disadvantage is that there must be a big sun]

What is the copra dryer:

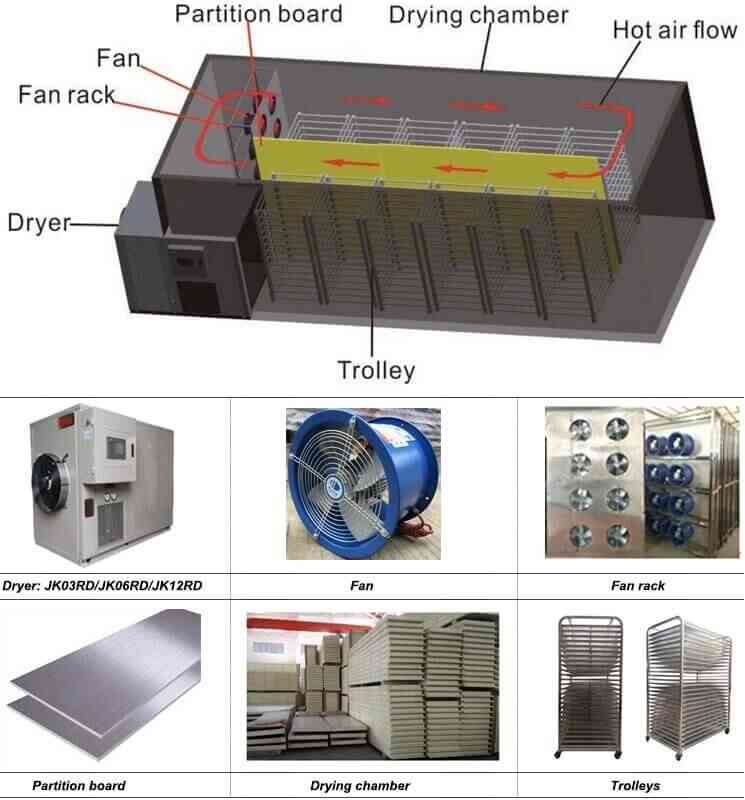

1. Heat pump copra dryer

The structure of the coconut meat dryer: 1. Heat pump heating unit. 2. Insulation box device. 3. Hot air circulation device. 4. Automatic dehumidification device. 5. Intelligent control device. The whole system of the host drying box adopts a SUS304 stainless steel inner plate design. The whole box adopts 100MM thick polyurethane insulation layer, which has good thermal conductivity. The patented air distribution system was independently designed and developed. The drying room has a uniform wind speed and heat distribution. materials are dried quickly, no mold, and reduced drying time. With a completely closed cycle, the heat is completely recovered, zero heat loss during the drying process can be achieved, and the energy utilization rate is improved, which is 33% higher than the average level of the same industry.

2.Continuous Mesh belt copra dryer

The main principle of the mesh belt dryer is to spread the wet materials to be dried on the mesh belt (or chainplate) evenly. The mesh belt copra dryer adopts a high temperature, corrosion, and oxidation resistance national standard mesh belt, which is driven by a transmission device. The mesh belt moves back and forth in the dryer, and the clean and stable hot air flows through the materials, and the water vapor is discharged from the moisture exhaust hole to achieve the purpose of drying. The linear speed of the mesh belt depends on the type of material and the water content. The airflow direction adopts negative pressure and porous air intake to ensure the effective drying area, the airflow and wind speed are evenly distributed, and the drying effect is improved.The equipment structure of the mesh belt type copra dryer mainly includes heat exchange furnace (heat source), heating fan (providing hot air to the drying box), mesh belt drying box, power distribution control cabinet, and feeding conveyor, Discharging conveying, and other parts are specially produced and manufactured for the drying process of copra. The dried copra is convenient for long-term storage and long-distance transportation and coconut oil.

Copra drying video:

Previous post:

Next post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.