How to Make Coconut Oil

What is coconut oil?

Coconut oil is a non-volatile oil refined from the seeds of the palm coconut tree. It is easily soluble in dichloromethane and petroleum ether (boiling range 65-70°C), slightly soluble in ethanol, and almost insoluble in water. Coconut oil has many uses and is not limited to cooking. In addition to seasoning foods and salads, coconut oil can also be used to maintain dry scalp and skin, treat acid reflux, and also used as a base component of soap, and even have a weight loss effect. Pure coconut oil is very expensive. Virgin coconut oil has the characteristics of high quality, natural processing, and no large amount of chemical additives.Coconut oil is obtained from fresh (dried) coconut meat and is white or light yellow fat. The liquid of this oil is as clear as water, and it is white after solidification. Because it has not been processed by high temperature and chemical substances, this oil retains the original composition and has the special smell and taste of coconut. Relatively speaking, cold-pressed virgin coconut oil is the most natural and has the highest nutritional value.

How to get coconuts in traditional way?

Coconut meat (dry) contains 65%-74% oil and 4%-7% moisture. Coconut trees grow on islands in tropical regions or along the coast of the mainland. The traditional oil extraction method for thousands of years is quite simple. As long as the coconut meat is made into pieces and boiled in water, the oil will separate and float on the water, and then the oil will be skimmed out. Another way is to squeeze coconut milk (also known as coconut milk) from the crumbs of coconut meat, and then allow it to ferment naturally for 24-36 hours so that the oil is separated from the water, and then the oil is taken out and heated for a short time to remove the water. This method of heating at a moderate temperature does not harm coconut oil. In addition, there are many methods for extracting coconut oil. The appearance, quality, taste, and fragrance of coconut oil obtained by different methods are different from each other.The modern process to make coconut oil:

Virgin coconut oil is extracted from fresh coconuts. The quality of fresh coconuts can be seen by the naked eye. The coconuts used in good coconut oil are all taken from specific coconut trees. They are native coconut trees, not late hybrids. Now the modern way to get coconut oil is the cold processing way. The most critical step to obtain coconut oil by cold processing is the drying of fresh coconut meat. Coconut meat needs to be pulverized into fine particles or coconut meat pieces and then dried with a through-flow mesh belt dryer produced by Henan Baixin. After drying, relevant squeezing is performed to obtain coconut oil.Belt dryer is continuous drying equipment for batch production. It is used for drying flakes, strips, and granular materials with good air permeability. It is suitable for dehydrated vegetables, catalysts, coconut meat, Chinese herbal medicines, etc with high moisture content and also the material that does not allow high temperature; this series of dryers have the advantages of fast drying speed, high evaporation strength, and good product quality. The paste-like material of the dehydrated filter cake needs to be granulated or made into the strip for drying.

Baixin multi-layer belt dryer is suitable for large-scale production of difficult-to-dry materials with a low drying rate. The dryer equipment has a compact structure, a small land area, simple operation, convenient maintenance, and stable operation. It can be designed into different hot air circulation drying forms according to the drying characteristics of the material. It is widely used in chemicals, food, agriculture, and other fields. With the advancement of enterprise technology and the improvement of product technology content, multi-layer belt dryers can meet large-scale production, diversification, centralized control, and continuous production. It has the advantages of high efficiency, energy-saving, and easy management.

For more details of coconut meat drying to make coconut oil, please contact us for more details. Baixin drying machine will help you make more money you.

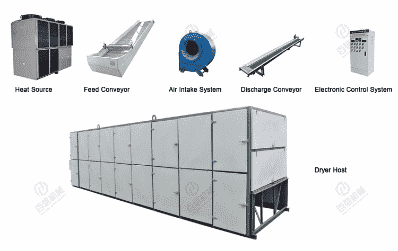

Composition of coconut Dryer:

Baixin mesh belt type dehydrated coconut dryer is composed of 4 parts: feeding conveyor, drying system, heat source, and discharging conveyor.

Technical data of coconut dehydrator machine:

.png)

Coconut drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.