How to Make Chilli Powder

How to get chilli powder?

Chili powder is a red or red-yellow, oily, and uniform powder. It is a mixture of red chili, yellow chili, chili seeds, and some chili stems. It has the inherent spicy aroma of chili and makes it pungent to sneeze. Chili powder is a condiment for people to make food, and it is also a necessary condiment for the family.As everyone knows, chili powder is generally ground directly from dried chilies. There are coarse and fine chili powders. Thick chili powder has a rough taste. Fine chili powder can be used to make chili sauce and cooking, which can be more fully integrated with cooking and show different flavors of cooking.

The authentic chili powder should be pounded with a stone mortar, or you can use dried chili directly, put it in the sun or bake it in a pot with a slow fire, and then pound it into a powder. Now chili powder is using a large amount of chili that is dried and then ground into a powder with a grinding machine.

How to dry chilli?

Therefore, one of the most critical steps to obtain a large amount of chili powder is to dry the chili. After a large amount of chili is dried, it is crushed into chili powder to meet various large-scale needs. Dried chilies still contain a small amount of water. The dried chilies are not only easy to grind into powder, which can extend the shelf life but also make them more fragrant. The pepper dryer produced by Henan Baixin is a small piece of equipment produced for the continuous drying of peppers. The specifications of the dryer machine start from six meters. It is designed according to your daily processing volume. It is popular among small and medium-sized processing plants and pepper planting. There are many cases of pepper drying done by Baixin Machinery. In terms of the types of peppers, there are red peppers, small green peppers, Chaotian peppers, sharp peppers, etc.; in terms of drying requirements, customers have whole peppers dried, or chili is cut into pieces and dried; in terms of drying capacity, it ranges from 50 kg to 1000kg. In the following, let's talk about the main points of drying pepper:1. Pick high-quality peppers

Fresh pepper picking chooses fully mature peppers with normal color and intact fruit; if you see obvious rot on the surface, and are too soft, they are all substandard products. This selection is very important. Only high-quality ingredients can make high-quality products.

A large number of fresh peppers must be well ventilated during transportation and stacking, especially the height of the stack should not be higher than 1m, and the stacking time should not exceed 36h;

2. Treatment

The picked peppers should be cleaned, and the stems, leaves, and dust of the peppers should be removed through pretreatment; If the impurities are not clean, it will affect the quality of the pepper powder.

3. Drying

The stacking thickness of peppers is generally 20-30 cm, and the thickness of the peppers should be consistent. If the stacking is too thin, the air permeability is good, and the wind resistance is small. Although it is conducive to heat exchange, the contact time between hot air and peppers is relatively shortened, and the heat utilization rate is relatively short. Now, if the stack is too thick, the resistance will increase, the hot air cannot penetrate the pepper, and the drying effect will be poor.

The temperature of chili drying should not be too high, because some ingredients are easily lost and destroyed at high temperatures. If you want to ensure the quality of chili drying, use the correct chili drying process to improve the yield, shape, color, and luster, and the scent of chili plays a very important role.

The chili that has been dried with a Baixin mesh belt dryer has good color, low damage rate, and high yield. The mesh speed, temperature, and humidity can be adjusted according to production needs to meet the needs of drying different types of peppers with different moisture content.

Baixin multi-layer belt dryer is suitable for large-scale production of difficult-to-dry materials with a low drying rate. The dryer equipment has a compact structure, a small land area, simple operation, convenient maintenance, and stable operation. It can be designed into different hot air circulation drying forms according to the drying characteristics of the material. It is widely used in chemicals, food, agriculture, and other fields. With the advancement of enterprise technology and the improvement of product technology content, multi-layer belt dryers can meet large-scale production, diversification, centralized control, and continuous production. It has the advantages of high efficiency, energy-saving, and easy management.

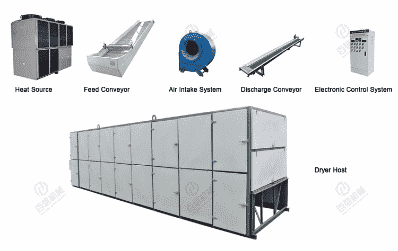

Composition of chilli Dryer:

Baixin mesh belt type dehydrated chilli dryer is composed of 4 parts: feeding conveyor, drying system, heat source, and discharging conveyor.

Technical data of chilli dehydrator machine:

.png)

Chilli drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.