How to Dry Tilapia Quickly/Dehydrate Tilapia in a Dehydrator

What are the tilapia drying problems?

- Tilapia is the main cultured aquatic product in China. Its meat is delicious, less prickly, high in protein, and rich in 8 essential amino acids needed by the human body. It is regarded as one of the main sources of animal protein in the future.

- Benefits: It has the functions of promoting physical development, protecting eyes, regulating blood lipid, and resisting aging.

- Drying is an important method for processing tilapia. Because dried tilapia food can meet the requirements of consumers in terms of nutrition, color, and flavor, and it is easy to preserve, it has been loved by consumers. Besides, sometimes people rely on drying to store fresh food safely. Dumping water when drying fish can reduce the breeding of bacteria, mold, and hungry insects. This means that it takes longer for dried fish to deteriorate, making it the perfect choice for camping, hiking, lunch boxes, long-distance driving, and other non-refrigerated environments.

The way to dry the tilapia:

- Wash tilapia, remove the scales and gills, cut the belly with a knife, take out the internal organs of the fish, and clean them again. If the internal organs are not cleaned, they will taste bitter.

- Apply salt evenly to the washed fish, and apply it to every place. Uneven application may lead to rot in some places. (If you want dried fish to be more delicious, you can use lemon, onion, and ginger, spiced powder, pepper, star anise, etc. )

- Put tilapia in a jar, stack the tilapia with its skin facing down, sprinkle some salt every two or three layers, cover it with bamboo slices, and marinate it with stone for one night.

- The next day, take out the dried fish and dry them in the sun. At noon, the sun is strong, so it could be covered with cloth. If there is enough sunshine, it could be dried in three days.

It's just the traditional way to dry the tilapia. If we use a dehydrator to dry the tilapia, what should we do?Using the dryer to dry the tilapia can save labor cost, and the tilapias are heated evenly without secondary operation. In addition, drying tilapia in this way can save cost, and the drying effect is better than the traditional drying method.

The tilapia dryer mainly adopts wave dryer technology.

- Adjustment of drying temperature. In the first stage, the temperature is 45℃, the humidity is 30%, the baking time is 6 hours, and the machine is stopped for 4 hours. In the second stage, the temperature is 45℃, the humidity is 20%, baking for 4 hours, and then stopping the machine for 4 hours. In the third stage, the temperature is 55℃, the humidity is 15%, and the bake for 3 hours. In the fourth stage, the temperature is 60℃, the humidity is 10%, and the bake for 2 hours.

- About the change of drying rate. The drying process of tilapia is not carried out at a constant speed, such as the rapid drying stage in the early stage, which is only the change of temperature and thickness, resulting in different slope changes of different curves. The drying rate of tilapia fillets first increases, then decreases, and finally tends to be slow, and the drying rate of thin fillets is much faster than that of thick fillets. When the drying temperature is constant, the drying speed of the fish fillet is affected by its thickness, and the thinner the fish fillet is, the faster it dries. On the contrary, the thicker it is, the slower it dries. When the thickness of fish fillets is constant, the temperature has a great influence on the drying speed of tilapia fillets. The higher the temperature, the faster the drying, otherwise the lower the drying speed.

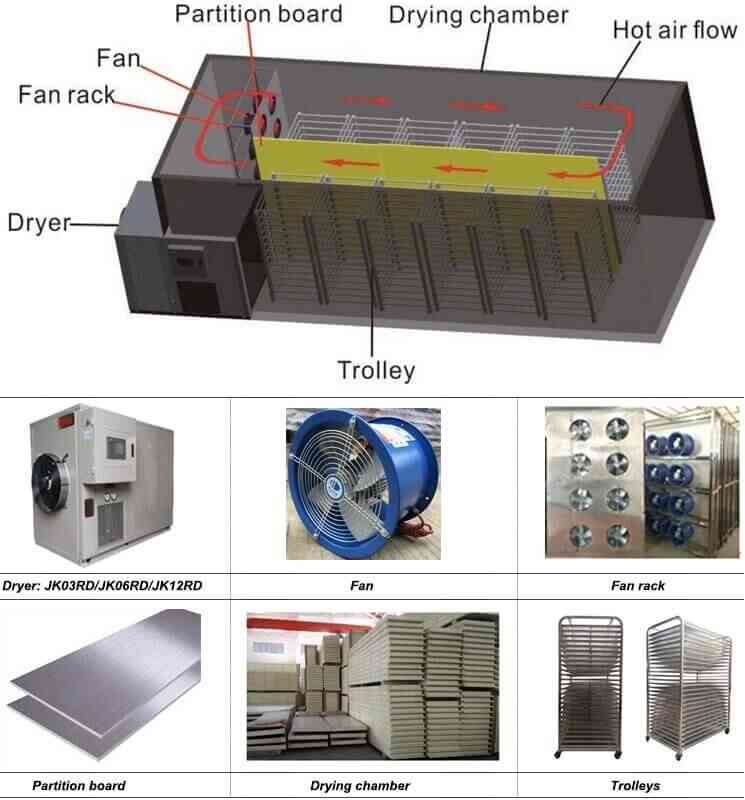

The principle of tilapia dryer machine working

Baixin air energy heat pump dryer uses the reverse Carnot principle. The refrigerant is compressed by the compressor to become high-temperature and high-pressure gas, enters into the heat exchanger through the pipeline, and then passes through the fan to remove the heat generated by the heat exchanger send it to the drying room to heat and dry the seafood products and other materials, so that the seafood products are dried, and the moisture is discharged from the moisture outlet. The dehumidification system has a heat recovery device, and the recovered heat is used to heat the fresh air, which can save 60%-70% of the fresh air preheating energy consumption.

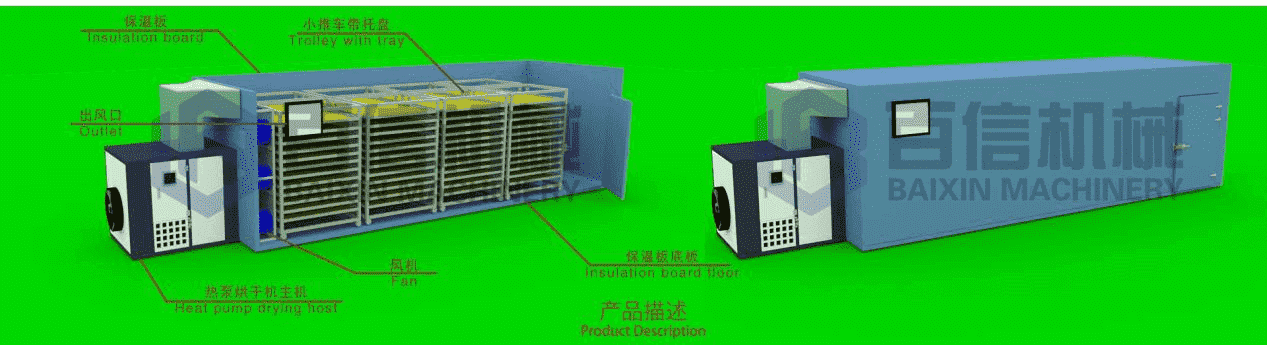

The tilapia heat pump dryer machine structure

Tilapia drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.