How to Dry Spice Quickly/Dehydrate Spice in a Dehydrator

Introduction to spices:

Spices refer to substances that can be used to formulate food flavors and enhance the flavor of foods. Food flavors are generally formulated into food flavors and then used for food flavoring. Some food flavors can also be directly used for food flavoring. The purpose of using food spices and flavors in food is to produce, improve or enhance the flavor of food.Spices can be widely used in medium and high-end household seasonings, green foods, health foods, suitable for various soups, cooking, sauces, seasoning sauces, canned food, vegetarian food, convenient snack foods, leisure and puffed foods, nutritious foods, hot pots Industries such as the preparation of soup base materials and so on.

.jpeg)

How to dry spices quickly/dehydrate spices in a dehydrator:

In the process of production and processing of spices, it is necessary to dehydrate and dry the spices, and to realize the dehydrate and dry the spices, it needs to use the dehydrate and dry equipment. Dehydration drying equipment refers to the combination of a series of mechanical equipment to dry the moisture or other liquid on the object by a certain technical means. At present, the popular drying technology has ultraviolet drying, infrared drying, electromagnetic drying, and hot air drying. They have their characteristics and are widely used in various mechanical equipment and food drying.Commonly used folk drying methods are:

1. Dry naturally, in the sun or the shade;

2. Hot air drying can be divided into many forms according to the heat source, continuous air supply form, and different equipment;

3. Vacuum drying;

4. Freeze-drying.

For example, Hot air drying can be selected. The mechanism of the drying process should be mastered during hot air drying. At the initial stage of drying, the moisture on the surface of wet spices evaporates quickly, which becomes the surface gasification stage. When the moisture drops to 10%-15%, the drying speed becomes slow. In the drying process, the coordination of the internal and external diffusion of moisture is quite important. If in the drying initial stage, the outer diffusion of moisture exceeds the inner diffusion, the spice surface layer becomes hard, not only hinder the continued evaporation of moisture but also delay the speed of drying. Therefore, drying to regularly turn and control a certain temperature. High temperature is easy to make the raw material in the aromatic and spicy components volatilization and cause the loss of other organic matter, so that the product turns brown, char taste, affect the appearance. If the temperature is too low, the drying time is too long, which affects the production efficiency, often aggravating microbial pollution and affecting sterilization.

Therefore, choose what kind of dry method, should look at the climatic condition of the place and decide, be in commonly 25-30 degrees the good method that dry from heat shade is to prevent essential oil loss, and the infrared ray illuminating method that gives newly recently is a good technology of dry fragrant plant. In addition, the most environmental protection method of drying, dry heating stage of drying and cooling stage, this is by nitrogen gas heating spices, after the compression of high pressure on the physical, cooling and condensation, and to realize the spices flavor substances in drying process no oxidation, essential oils, no loss, low moisture after drying, dry sterile and safe environment.

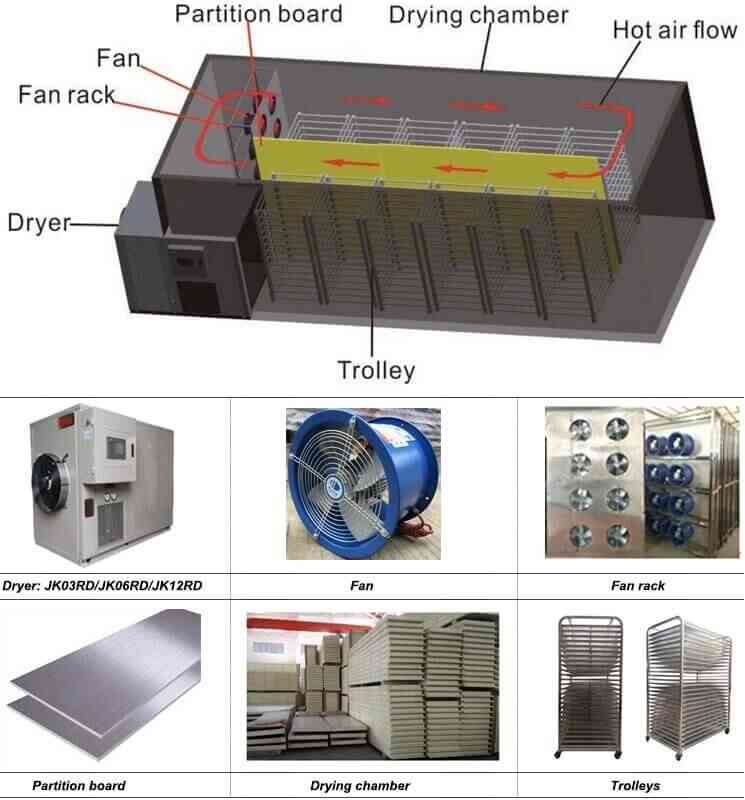

The principle of spices dryer machine working:

Baixin air energy heat pump dryer uses the reverse Carnot principle. The refrigerant is compressed by the compressor to become high-temperature and high-pressure gas, enters into the heat exchanger through the pipeline, and then passes through the fan to remove the heat generated by the heat exchanger send it to the drying room to heat and dry the seafood products and other materials, so that the seafood products are dried, and the moisture is discharged from the moisture outlet. The dehumidification system has a heat recovery device, and the recovered heat is used to heat the fresh air, which can save 60%-70% of the fresh air preheating energy consumption.

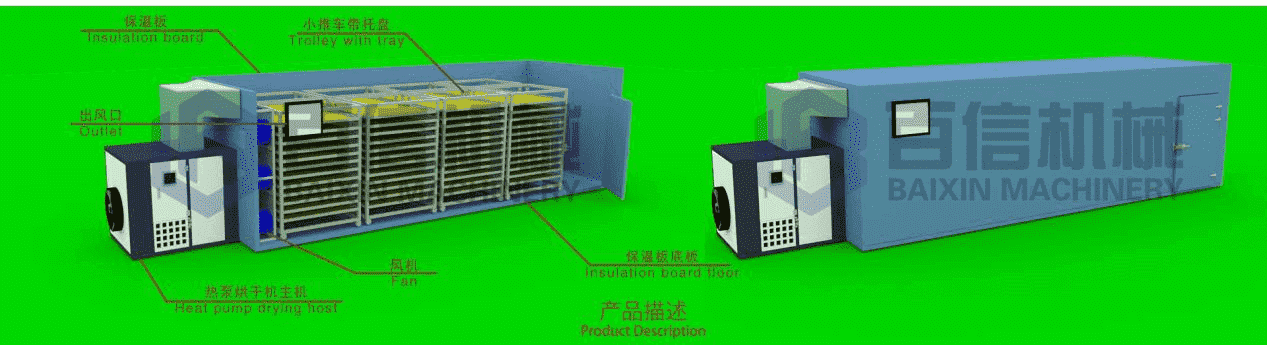

The spices heat pump dryer machine structure:

Spices drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.