Dehydrate Soybean in a Dehydrator/Soybean Drying Process

Introduction to soybean:

Soybean is originated in China and widely cultivated all over the world. It has been cultivated for 5000 years. It is a kind of crop whose seed is rich in plant protein. Soybean is most commonly used to make various soybean products, extract soybean oil, brew soy sauce and extract protein.

Soybean processing steps:

In the process of industrial production of natto, the suitable automatic cleaning, soaking, cooking, constant temperature fermentation and low temperature drying were selected according to the yield.1. Raw material treatment

The raw soybeans harvested from all over the world, after passing the grade inspection, become raw soybeans, and then carry out selective treatment to remove inclusions and uniform grain shape, and then put them into 30 kg paper bags for storage. The storage temperature should be controlled at 15 ℃, and the humidity should be controlled at about 60% in the low temperature warehouse, otherwise the soybeans are easy to deteriorate and cause losses.

2. Washing and dipping

The selected soybeans are cleaned with a bean washer to remove the sand, dust and organic matter attached to the surface. The purpose of impregnation is to make the water absorbed into the seed of raw soybeans, soften the tissue and make it easy to cook, so that natto can easily use the soybean ingredients. When the weight of soybean is 2.3-2.4 times, the two seeds can be seen to expand to almost no space. The soaking time varies according to the variety and size of soybean, but the most influential factor is the water temperature. The soaking time is 23-24 hours at 10 ℃ and 17-18 hours at 15 ℃, The immersion time is 13-14 hours at 20 ℃ and 7-8 hours at 25 ℃. Although the following cooking process can kill the mixed bacteria, the residual metabolites will affect the growth of natto bacteria, which can completely inhibit the reproduction of natto bacteria when it is severe. Therefore, it is necessary to take low temperature as far as possible to inhibit the growth of mixed bacteria. The ideal situation is to select the water temperature below 10 ℃ for soaking, and control the temperature in the refrigerator to 5 ℃ for soaking in a small amount of production, It can be cooked in about 24 hours. The length of soaking time can be judged according to the size of beans, tissue condition and water absorption. To determine the length of soaking time, 100 grams of soybean raw materials can be put into a small bag for soaking, which can be taken out in a certain period of time and weighed after the moisture is removed as far as possible.

3. Cooking

The function of cooking is to kill the soil microorganisms on the surface of soybean, soften the soybean tissue, and make the soluble components of seeds soak into the surface of soybean skin. Therefore, natto is easy to absorb nutrients after inoculation, and the enzymes in vitro of natto are easy to soak in and decompose the soybean components. First, increase the pressure of pressure cooker to about 5kg, then put two sandbags of impregnated soybeans into the cooking tank, open the upper cover, lock the door, open the drain valve and exhaust valve, and then introduce the boiler steam into the cooking tank through the steam piping. As soon as the drain pipe of the cooking tank is opened, the incoming steam first discharges the condensed water and the cooking juice produced by soybean cooking to the outside, At this time, the steam is discharged. Close the drain valve and then the exhaust valve. After 10-20 minutes, the steam pressure will rise to 1.0-2.0 kg. Keep it for 30-40 minutes, then close the steam valve. Wait for 10-15 minutes to finish cooking. After finishing cooking, slowly open the valve of water distribution pipe and exhaust pipe. After releasing steam, open the cover.

4. Inoculating natto

The operation temperature is between 70 ℃ and 90 ℃, and the spores of natto fungus are evenly attached to the surface of cooked soybean. This operation is called inoculation. 5cc of soybean fungus liquid can be inoculated into a soybean sandbag. The soybean fungus liquid is the suspension of natto spores. There are about 100 million to 200 million spores in 1cc, and about 4000 spores are attached to 1g of cooked soybean, About 1300 spores are attached to the surface of 1 soybean, and 5cc raw bacteria should be evenly distributed on a sand bag. It is necessary to increase the sterilization water increments in advance, to cool the boiled drinking water to 50 degrees Celsius, spray two sandbags and dilute them to 2 kilograms, and when the watering kettle is spread, it is necessary to dissolve 2.5 kilograms of sterile water.

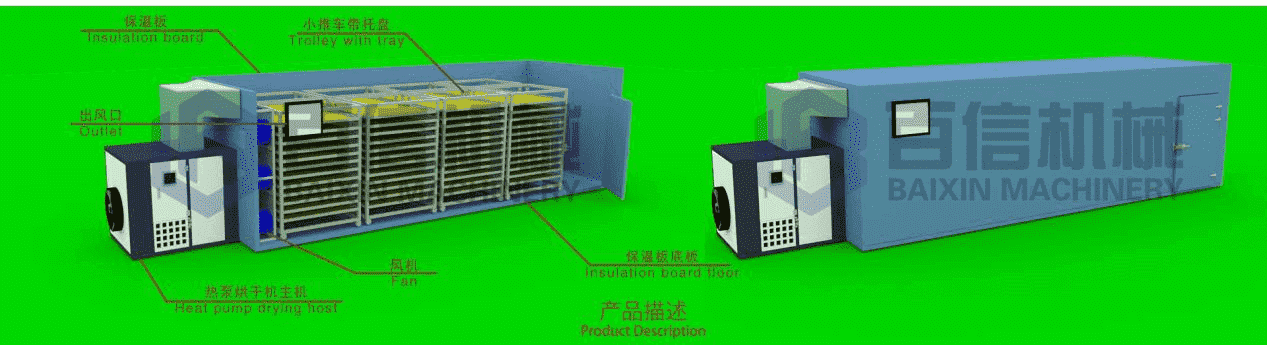

Soybean drying process:

6p drying and dehumidification integrated host is selected to configure polyurethane thermal insulation drying room with 5.5m long, 3M wide and 2.2m high. Six material trucks are built in. The single truck is 1.2m long, 1m wide and 1.7m high. It is divided into 12 layers of grid trays. Each truck is loaded with 300kg. One batch is loaded with 1200kg. The temperature range is set at 50 ℃ - 60 ℃ and the time is set for 20 hours. Finally, the moisture content reaches 12%. The drying process is over

Recommendation of Soybean dryer/drying machine

Commercial 100-3000kg/h large amount of dehydration wide application and easy operation

Heat pump drying machine use the principle of inverse Carnot cycle. It absorbs low-temperature heat energy in the air, which becomes high-temperature heat energy after efficient heat collection and integration by the heat pump system, and is transported to the drying room for cyclic heating and drying of materials.It refers to exhausting the hot and humid air in the drying room directly to the outside of the drying room through dehumidification device, and then replenishing natural fresh air.

Hot air circle drying machine belongs to high temperature heat pump unit. Its working principle is: the working fluid of the heat pump is compressed by the compressor, becomes high temperature and high pressure gas, enters the condenser, condenses and liquefies the heat, and is used for air heating in the drying room. The moisture in the material is vaporized and evaporated by the form of hot air, and the evaporated water vapor is discharged by the moisture discharge system, thereby achieving the purpose of drying the drying material.

Soybean drying video:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.