How To Dry Onion/Dehydrate Onion In a Dehydrator

How To Dry Onion/Dehydrate Onion In a Dehydrator

Onion contains prostaglandin A, which can reduce peripheral vascular resistance and blood viscosity. It can be used to reduce blood pressure and prevent colds. In addition, onions have effect of remove oxygen free radicals in the body, enhance metabolism, resist aging, and prevent osteoporosis. It is a health food suitable for middle-aged and elderly people. Onions are widely distributed in the world, However, onions are prone to storage rot and rooting after harvesting, leading to storage failure. Therefore, dried onions have become an important means of convenient storage and are widely used. After drying, they are used as condiments, mainly used in canned food and convenience food.

1.How to dry onion at home

1.Material selection. The raw materials should be medium or large healthy bulbs. The onions are required to be mature, tight in structure, small in neck, white or light yellow in flesh, strong in spicy taste, no green skin or little green skin, and dry matter not less than 14 %.2. Organize, cut off the stem and root, and peel off the outer layer.

3. Divide and cut into thin slices with a thickness of 2 to 3 mm.

4. Washing: Wash the sliced green onion fully in clean water.

5. To protect the color, put the onion in 0.2% sodium bicarbonate solution for about 2 to 3 minutes, and then removed and drained.

6, air-dry, drain the water on the surface of the onion.

7.Dehydrate, spread the onion slices evenly, and dry them in a ventilated place for 2-3 days.

2.How to use dehydrator machine to dry onion in large quantity ?

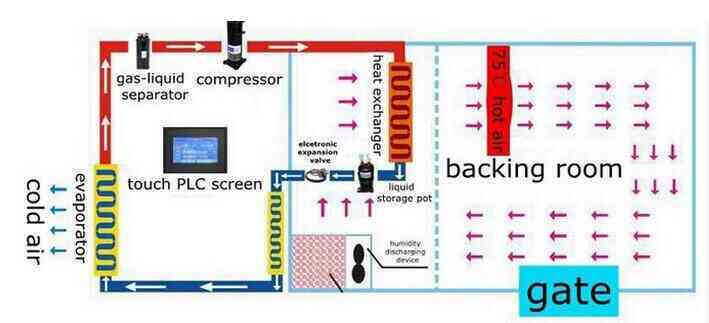

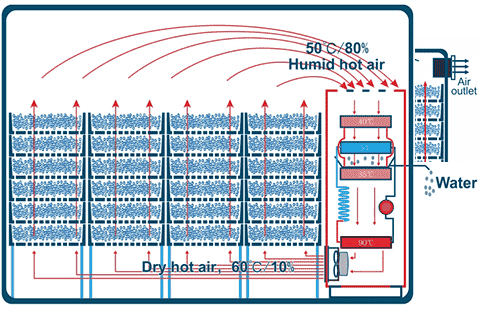

The heat pump dryer is a new type of high-efficiency energy-saving dryer. Its working principle is based on the principle of reverse Carnot cycle, using a small amount of electric energy, and using a compressor to evaporate the common substance into a gaseous state in the evaporator after passing through the expansion valve. It also absorbs a large amount of heat energy in the air. The gaseous working medium is compressed by the compressor to become a high temperature and high-pressure gas, and then enters the condenser to release heat to dry the material, and heating continuously in this way, they can get the dry material.1. Temperature: Onions generally have a relatively high water content, so it needs to be dry with low temperature and hot air. The high temperature will destroy the nutritional value of onions. The drying temperature of onions can not exceed 50 ℃. It can be carried out in multiple stages. The first phase temperature is 50-40℃, the second stage is 40-30℃, and the third stage will drop to about 35℃.

2. Humidity: To control the amount of moisture discharged, this is one of the important factors that determine the drying quality, and it is critical to control the dehydration speed.

3. Drying time: The drying cycle of onions is generally about 15 hours, and rapid drying will destroy the drying quality.

3.How to choose right dehydrator machine to dry onion ?

Good heat pump dryer has few parts as below:1 whole unit with stainless steel, anti-corrosion, and ruts-proof

2 titanium golden heat exchangers.

3 ozone generators for sterilization

4 intentional famous brand compressor

5 360 degrees steering wheel

6 tray material is food grade PVC and 340 steel stainless material, tray material can be customized.

7 transparent toughened glass observe drying condition form outside

8 PLC intelligent control panel: 18-80°C drying temperature-humidity setting, drying time setting, phase(stage) setting can meet multiple drying demands, automatic working setting.

Dehydrate onion in a dehydratore/Rcommendation of onion drying machine

1).The first method:Household Commercial All-in-one drying equipment without installation for any materialDrying essence is take moisture away, but takes away the moisture temperature is not the most critical factor. The key for drying is depending on relative humidity within certain space, Baixin Company took advantage of the dry essence, originality developed a "Closed Cycle" dryer, changed the traditional heat pump dryer "bake" to "dehumidifier”. Its several advantages were unmatched by the traditional heat pump dryer.

Baixin Food Dehydrator has a compact structure, great energy-saving, wide application, high drying quality, easy operation, simple installation and removable. it is the best drying equipment for small firms, drying experiment and scientific research. The users only connect the power to use, is the easiest operation heat pump dryer.

The heat pump drying machine is Commercial All-in-one universal drying equipment without installation,suitable for 85% of food vegetable fruit mature material.This kind of dryer has the advantages of easy operation low cost clean and sanitary small area occupy.

1:Applicable:Vegetable,fruit,meat,seafood,agricultural ,noodle,wooden

2:Output:100-3000kg/h

3:Heat pump model:1P/2P/3P/6P/8P/10P/15P/20P/30P/40P/60P

4:Drying time:Depends on different drying materials

5:Core advantages:Energy saving and environmental protection, simple or without installation, easy operation operation, wide application for food vegetable fruit dryer,small area occupy

2):The second method:Commercial 100-3000kg/h large amount of dehydration wide application and easy operation

Heat pump drying machine use the principle of inverse Carnot cycle. It absorbs low-temperature heat energy in the air, which becomes high-temperature heat energy after efficient heat collection and integration by the heat pump system, and is transported to the drying room for cyclic heating and drying of materials.It refers to exhausting the hot and humid air in the drying room directly to the outside of the drying room through dehumidification device, and then replenishing natural fresh air.

Hot air circle drying machine belongs to high temperature heat pump unit. Its working principle is: the working fluid of the heat pump is compressed by the compressor, becomes high temperature and high pressure gas, enters the condenser, condenses and liquefies the heat, and is used for air heating in the drying room. The moisture in the material is vaporized and evaporated by the form of hot air, and the evaporated water vapor is discharged by the moisture discharge system, thereby achieving the purpose of drying the drying material.

Onion drying video:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.