How to Dry Mushrooms in the Oven

How to Dry Mushrooms in the Oven

Mushroom is the second largest edible fungus in the world. It has high nutritional value and delicious taste. In addition to being a delicious food, it also has high medicinal value and has always been very popular among people.

However, fresh mushrooms have a short shelf life and are prone to spoilage, so dried mushrooms that can be stored for a longer period of time have become a more popular product. So now let's explore how to dry mushrooms in the oven.

Drying mushrooms in the oven can be divided into two types according to the output, one for household use, and one for dry mushrooms processing plants.

At home drying mushrooms in the oven.

Details are as follows. First, clean the mushrooms, then cut the mushrooms into 3 mm thick slices, spread the sliced mushroom slices on a baking tray, and the oven temperature reaches 65 ℃. Then put the mushrooms and the baking tray in, bake for about an hour, take out, turn over and bake for another hour. If there is moisture on the surface of the mushrooms, you can use a paper towel or dry cloth to remove the moisture. Repeat the above steps until the mushrooms are completely dry. Baked mushrooms should be kept in an airtight container. This method is cumbersome and only suitable for drying a small amount of mushrooms.At the factory uses oven to dry mushrooms.

First of all, we need to know that the oven used in the dry mushrooms processing factory is a professional high-volume oven. Introduced below are the mushrooms mushrooms drying ovens produced by experienced Baixin machinery, and they are also the most commonly used mushrooms drying oven on the market. mushrooms mushrooms drying ovens can be divided into three types according to the output: continuous mesh belt mushrooms mushrooms drying oven, output 300-2000kg/h; heat pump mushrooms mushrooms drying oven, output 100-5000kg/batch; integrated mushrooms mushrooms drying oven, output 100-1500kg/batch. In addition to the difference in output, the heat source and working principle of the three ovens are also different. Each has its own advantages, which are described in detail below.

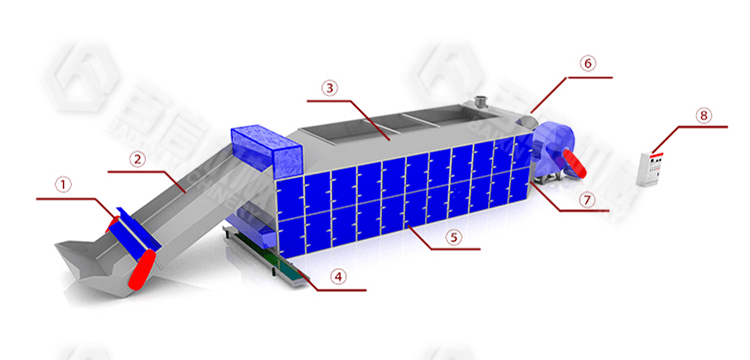

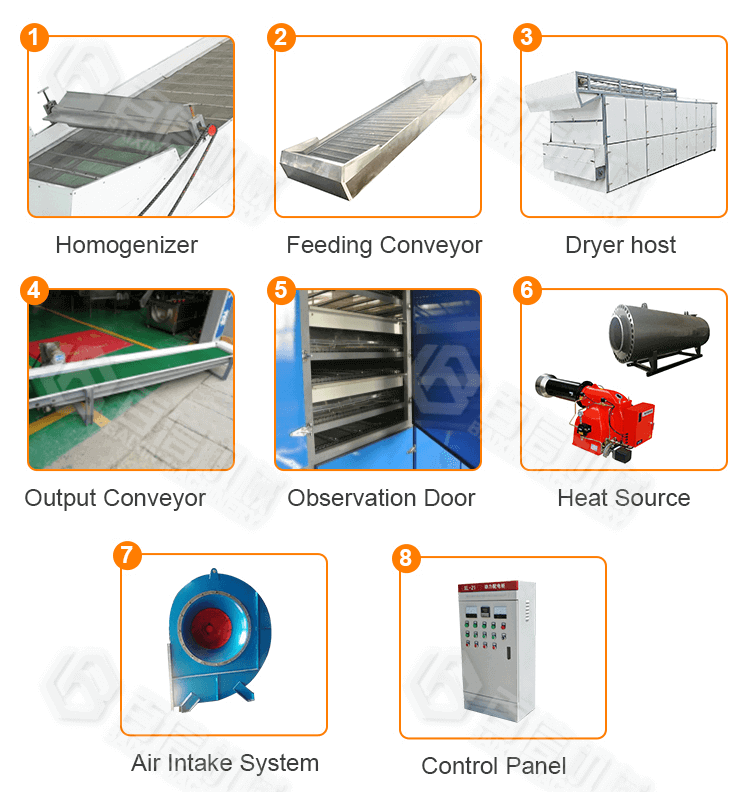

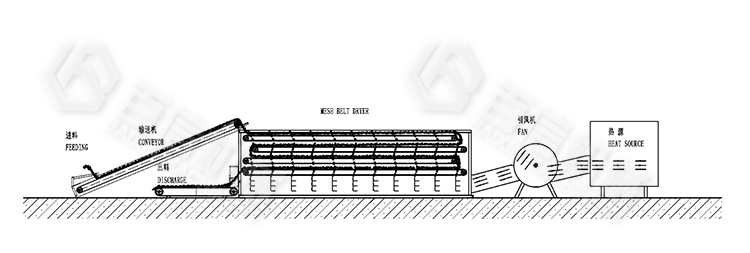

1.Continuous Mesh Belt Mushroom Drying Oven

This is a continuous production drying equipment, the main heating way has electric heating, steam heating, hot air heating, the output is 300-2000kg/h, and the heat source can be coal, wood chips, natural gas, diesel, propane, electricity ,etc.The main advantages are fast drying speed, continuous automatic work, high output, flexible mobility, simple or without installation, etc.

Its main working principle is to spread the material evenly in the network. The material is moved in the dryer by the operation of the machine, and the hot air draws out the water vapor of the material. so as to achieve the purpose of drying. The operation temperature is 40-120 degree centigrade. And the dry cycle is 1-5 hours. The components of this continuous mesh belt mushroom dryer include: Homogenizer, Feeder Conveyor, Mesh belt fruit dryer host, Heat source,Air Intake System, Control panel, Observation door, Output conveyor. The specific component and principle are as follows:

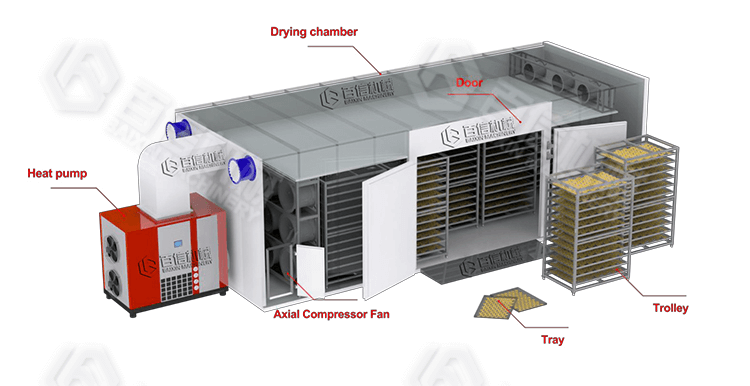

2.Mushroom Heat Pump Drying Oven

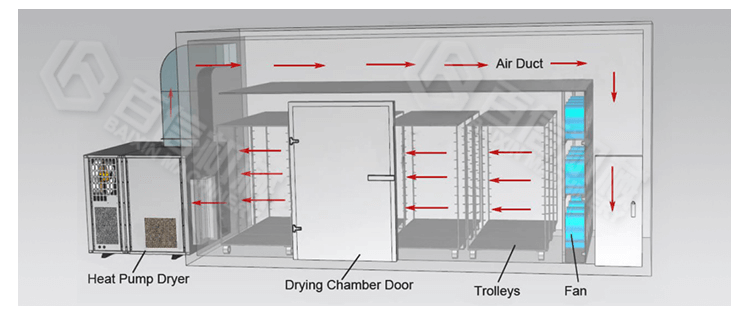

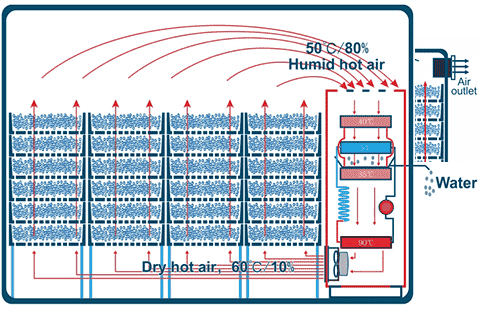

This is a drying equipment for box batch production, the output is 100-5000kg/batch, and the heat source can be electricity, coal, wood chips, natural gas, diesel, propane, etc.It adopts the principle of reverse Carnot cycle. It absorbs low-temperature heat energy in the air, and becomes high-temperature heat energy after efficient heat collection and integration of the heat pump system, which is transported to the drying room to circulate heating and drying the mushroom, and the hot and humid air in the drying room is directly discharged to the outside of the drying room through the dehumidifier.

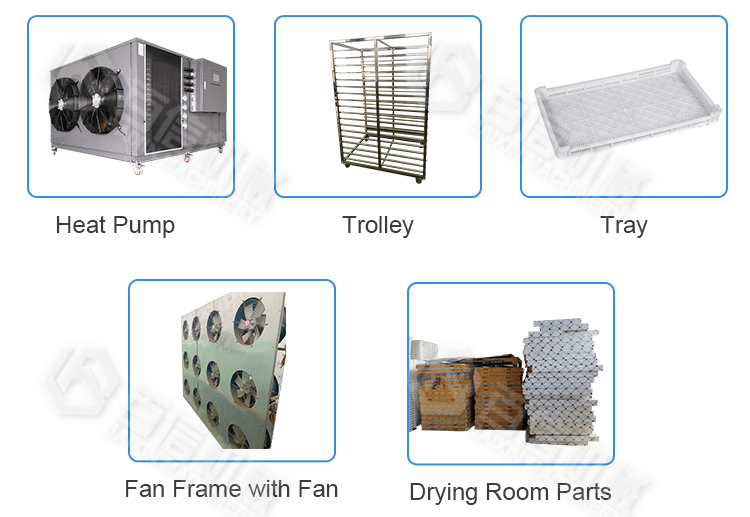

The mushroom heat pump drying room can quickly remove the water in the mushroom without affecting the original color, shape and nutrient content of the mushroom. The mushroom heat pump drying room is equipped with a computer control system, which can realize automatic temperature control. The drying temperature range of the heat pump dryer is 20-80°C. It has the advantages of strong drying capacity, better drying effect, simple operation, and 70% energy saving by adopting a heat pump system. The components of this mushroom heat pump drying room include: Heat Pump, Trolley Tray, Fan Frame with Fan(Axial Compressor Fan), Dryer Room Parts. The specific component and principle are as follows:

3.All-in-one Mushroom Drying Oven

This is a "closed Cycle" dryer, the output is 100-1500kg/batch, the heat is source mainly electricity, can also be coal, wood chips, natural gas, etc. We all know that the essence of drying is to take away moisture, but takes away the moisture temperature is not the most critical factor. The key for drying is depending on relative humidity within certain space, This closed-loop dryer is carefully developed by Baixin Company by using the essence of drying, changed the traditional heat pump dryer "bake" to "dehumidifier”.Its several advantages were unmatched by the traditional heat pump dryer. This dryer has a compact structure, great energy-saving, wide application, high drying quality, easy operation, simple installation and removable. it is the best drying equipment for small firms, drying experiment and scientific research. The users only connect the power to use, is the easiest operation heat pump dryer. The components of this all-in-one mushroom dryer include:Power jack, Water outlet, Exhaust air outlet, Supporting wheels, Controller(PLC control panel), Door lock, Observation window, Circulating Air Inlet, Outlet for hot and dry air, PP tray, Stainless steel tray, Supporting racks for trays. The specific component and principle are as follows:

That's all for the answer to how to dry mushrooms in oven, if you have any further questions, welcome to contact us at any time.

Mushroom Drying Oven video:

Previous post:

Next post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.