How to Dry Hetian jade jujube/Dehydrate Hetian jade jujube in a Dehydrator

Introduction to Hetian jade jujube:

Hetian jade jujube has large fruit, thin skin, deep red color, thick flesh, sweet taste and high quality. It is suitable for drying and processing wine jujube and honey jujube. Hetian jade jujube is dried in the air. It has deep red color, large fruit, rich nutrition, high sugar and vitamin content.Hetian jade jujube drying process:

In the whole drying process, keeping the relative humidity of the environment can promote the sugar conversion, but the excessive relative humidity of the environment will affect the water evaporation efficiency of Hetian jade jujube. It has been proved that 55% relative humidity is the best environment for Hetian jade jujube drying. This relative humidity can also partially inhibit the evaporation speed of Hetian jade jujube external water in the later drying period, and make the internal water of Hetian jade jujubee slowly permeate and evaporate outward, so that the internal and external evaporation of Hetian jade jujube basically tends to be the same.1. Preheating

If the jujube fruit directly enters the 60 ℃ high temperature environment suitable for sugar transformation at room temperature, the instant large temperature difference will cause the cells of Hetian jade jujube to have biological self-protection reaction, and the epidermal cells will contract, which will cause the jujube fruit crust to harden and hinder the internal water evaporation of Hetian jade jujube.

Therefore, Hetian jade jujube needs to be fully preheated and slowly warmed in the early stage of drying, so as to make jujube adapt to the slow temperature rising process and prepare for the next step of moisture evaporation. The specific measures are as follows: keep it at 35 ℃ for 8 hours, heat it up to 45 ℃ for 7-8 hours, and wrinkles will appear when pressing the jujube.

2. Evaporation

When the drying room is heated to 46 ℃ - 48 ℃, there will be a layer of small water droplets on the surface of jujube, indicating that a large amount of free water inside the jujube cells evaporates. At this time, the temperature must be increased to 65 ℃ within 8-12 hours, and never exceed 70 ℃. At the same time, the dehumidification operation should be strengthened to keep the indoor temperature from fluctuation and continue to evaporate water. When there are wrinkles on the surface of jujube fruit, it means that the drying is normal. A large amount of water evaporation can be completed within 6 hours.

3. Drying

After the evaporation stage, the moisture in jujube is not much, so we should pay special attention to the temperature control, not too much, 50 ℃ is better. At this time, the relative humidity also dropped down, such as higher than 60% can be slightly dehumidified. With the moisture balance in jujube, the purpose of drying is achieved. Take care to transport the dried samples out in time.

4. Cooling

After drying, the jujube fruit must be ventilated and cooled before stacking. If the Hetian jade jujube just transported from the drying room is stacked together, under the action of high temperature and waste heat, the polysaccharide inside the jujube fruit is easy to ferment and deteriorate, and the original pectin inside the jujube will also decompose the pectin and pectin acid, which will make the jujube deteriorate. The early and dry jujubes have sour taste, which will reduce the quality of Hetian jade jujube. Therefore, after baking, it must be cooled before storage.

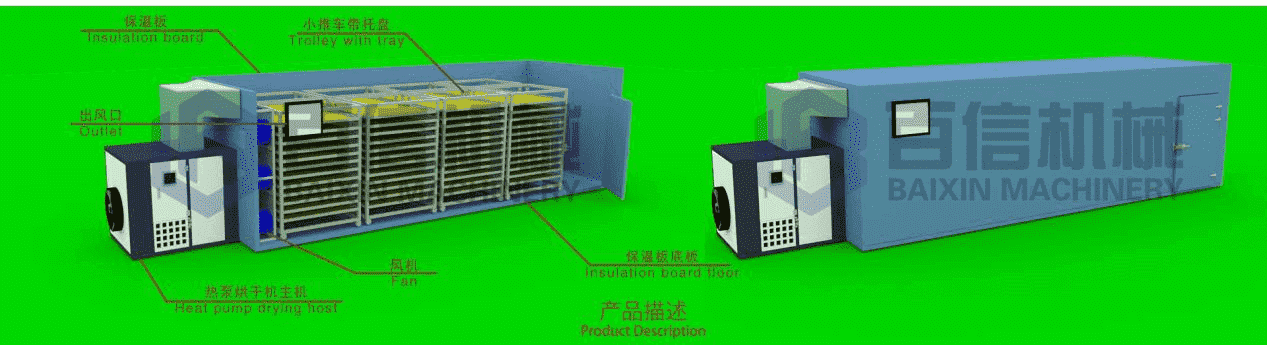

Recommendation of Hetian jade jujube dryer/drying machine

Commercial 100-3000kg/h large amount of dehydration wide application and easy operation

Heat pump drying machine use the principle of inverse Carnot cycle. It absorbs low-temperature heat energy in the air, which becomes high-temperature heat energy after efficient heat collection and integration by the heat pump system, and is transported to the drying room for cyclic heating and drying of materials.It refers to exhausting the hot and humid air in the drying room directly to the outside of the drying room through dehumidification device, and then replenishing natural fresh air.

Hot air circle drying machine belongs to high temperature heat pump unit. Its working principle is: the working fluid of the heat pump is compressed by the compressor, becomes high temperature and high pressure gas, enters the condenser, condenses and liquefies the heat, and is used for air heating in the drying room. The moisture in the material is vaporized and evaporated by the form of hot air, and the evaporated water vapor is discharged by the moisture discharge system, thereby achieving the purpose of drying the drying material.

Hetian jade jujube drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.