How To Dry Green Bean Quickly/Dehydrate Green Bean In a Dehydrator

How To Dry Green Bean

Green Beans are annual vegetables of the cowpea in the Leguminosae family of the order Rosales. Also known as cowpea, long cowpea, belt bean. Green Beans are an agricultural vegetable, it can be divided into long beans and short beans. The sowing time can be divided into spring and autumn, and the maturity time is about 2 to 3 months. Beans can be used in many dishes, and it is a kind of vegetable with a high degree of popularity. It is rich in protein, carotene, high nutritional value, and good taste, it is one of the popular vegetables widely cultivated in the world, and its popularity ranks first among all kinds of vegetables. Beans are highly adaptable. They can be cultivated in open fields or protected fields and can also be produced on an annual basis and be marketed in four seasons.

How to dry green beans in a traditional method?

Dried green beans, also called dehydrated green beans, usually use cowpeas and kidney beans as raw materials. After being cooked at a high temperature, they are dried in the sun or machine. After drying, the finished product is black and fragile. The traditional method is to dry naturally, and hang them one by one on the drying rack, and don't let the beans overlap each other. Hang the beans in a well-ventilated and well-lit place during the day, and put them in the house at night to prevent the beans from getting wet with dew. It will take 3-7 days when the weather is sunny and well ventilated, the beans will be completely dehydrated and become real dried beans.

How to dry green beans in large quantities?

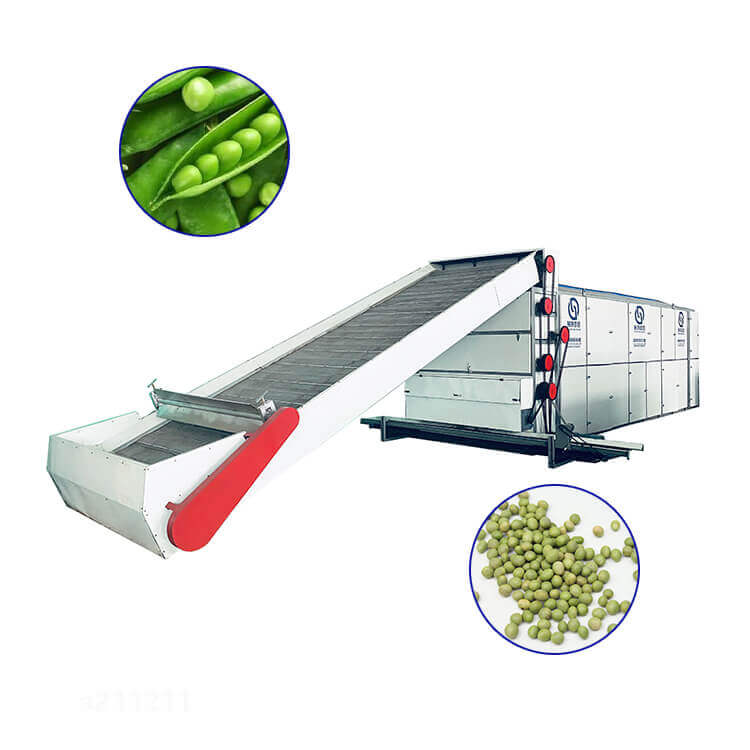

Green Bean dryer is also called mesh belt type dehydration. Mesh belt green bean dryer is continuous drying equipment for mass production, used for drying flakes, strips, granules, and part of paste materials with good air permeability. It is especially suitable for materials with high moisture content and heat sensitivity, such as dehydrated vegetables and Chinese herbal medicine pieces, and farm crops. It has the advantages of a high drying rate, high evaporation intensity, and good product quality.

What are the advantages of a green bean mesh belt dryer?

1: The mesh belt has good air permeability, and the product drying cycle can be adjusted arbitrarily.

2: The equipment runs smoothly and the materials are not easily damaged.

3: Large drying area and high strength.

4: Hot air circulation structure, uniform temperature, and reduced energy consumption.

5: According to customer needs, it can be divided into several units, and each unit can independently control the circulation loop.

6: The selection of heat sources is diverse, which can be electric heating, gas heating, hot air heating, thermal heating, etc.

Henan Baixin Machinery specializes in the production of mesh belt vegetable dryers. While drying the vegetables, it ensures that the vegetables do not change color or lose their nutrients. High efficient vegetable green beans mesh belt drying machine is specially designed according to the moisture content of the beans and output non-standard design. We welcome all the customers from the world come to visit our factory and make on-site inspections for further won-won cooperation.

Large amount of dehydration 200-5000kg/h food vegetable drying machine continuous automatic work easy operation

Green bean Dryer Machine is a kind of continuous production drying equipment, the main heating way has electric heating, steam heating, hot air heating. Its main working principle is to spread the material evenly in the network. The material is moved in the dryer by the operation of the machine, and the hot air draws out the water vapor of the material. so as to achieve the purpose of drying.The operation temperature is 40-120 degree centigrade. And the dry cycle is 1-5 hours.

Green bean drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.