How to Dry Coffee Beans/Dehydrate Coffee Beans in a Dehydrator

What do you know about coffee beans?

Coffee Beans, divided into washing type and dry type, flat beans and round beans. The coffee beans have dark and light colors. Through deep roasting, the coffee beans burst, doubled in volume, and reduced in weight by nearly 1/4. The coffee beans gradually generate volatile flavor oils during the roasting process, so that the various flavors reach a perfect balance. Even if the coffee beans are in the same producing country, the difference in climate, altitude, and soil quality in each region will have subtle effects on the flavor and quality of coffee beans, as well as their own characteristics. The earliest way for the Arabs to eat coffee was to chew the whole fruit to absorb its juice. Later, they mixed ground coffee beans with animal fat to use as a physical supplement for long-distance travel. It was not until about 1,000 AD that green coffee beans were boiled in boiling water to become an aromatic beverage. After another three centuries, the Arabs began to roast and grind coffee beans.Ethiopia is the birthplace of the famous Arabica coffee bean. Of all the regions, Sidamo and Yegachefi stand out, and the tradition of harvesting wild coffee beans continues to this day. Over 1500 meters above sea level, the coffee garden has evolved and adapted for more than one thousand years, forming unique coffee terroirs. Ethiopian coffee mostly washed beans, is floral, smooth, and subtle, with strong chocolate and fruit flavors. Ethiopian coffee grown in the natural wild environment is called "coffee of the wilderness". It retains the most original and natural taste of coffee beans and has the most direct and full expression of the terroir. Its intense and complex fruit aroma has made it an international sensation almost overnight, making it a connoisseurs' favorite, and expensive.

How to use a dehydrator to dry coffee beans?

Most people think of baking as nothing more than frying raw beans over a fire. Roasting is the most difficult step in the process of coffee processing. It is a science as well as an art, so experienced roasters enjoy a highly respected status in European and American countries.The baking process can be divided into the following three stages:

- drying in the early stage of baking, raw beans began to absorb heat, internal water gradually evaporated. At this time, the color gradually from green to yellow or light brown, and the silver film began to fall off, you can smell a light grass smell. The main role of this stage is to remove moisture, which accounts for about half of the roasting time, as water is a good heat conductor and helps to roast the contents of the coffee bean. So, while the goal is to get rid of water, bakers try to temperature the water so it doesn't evaporate too quickly; In general, it is best to control the water reaches the boiling point and turns into steam at 10 minutes. At this point, the interior is fully baked and the water begins to evaporate, flushing out the outside of the bean.

- Roasting at a high temperature of about 160 degrees Celsius, the water inside the beans evaporates into a gas and begins to flush out the outside of the bean. At this time, the internal heat of the raw bean from endothermic to exothermic, the first crack. After the crack, the beans are absorbed again, and the pressure inside the beans is extremely high, up to 25 atmospherics. The heat and stress begin to deconstruct the old tissues and form new compounds that give coffee its taste and taste. At about 190 degrees Celsius, the transfer between endothermic and exothermic occurs again. Of course, high-temperature cracking continues to take place, turning the beans from brown to dark brown and gradually into the re-roasting stage.

- After roasting, coffee must be cooled immediately to quickly stop high-temperature cracking and lock the flavor. Otherwise, the high temperature in the bean, if it continues to work, will burn off the aromatic substance.

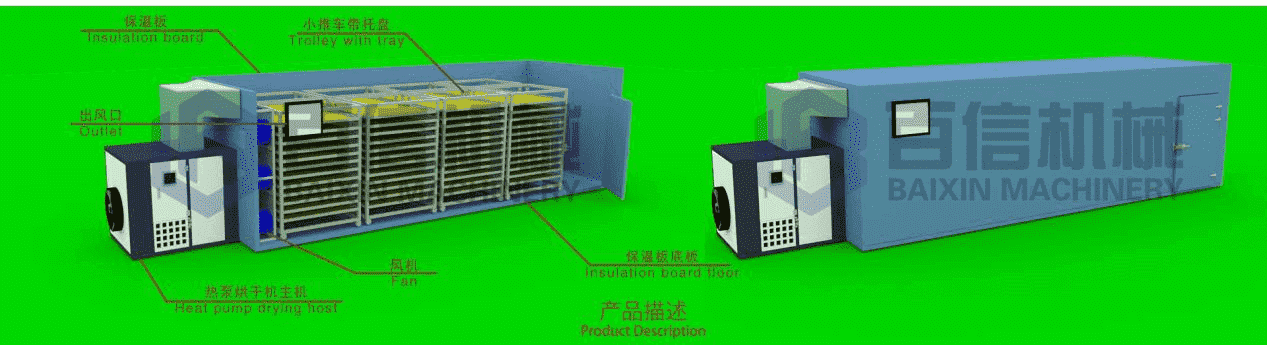

Henan Baixin company has various types of coffee beans drying equipment, small movable ovens, large closed drying rooms, and fully automatic drying lines. Whether you are an individual user or an enterprise, we can provide suitable coffee beans drying machines with models complete. Not only that, but we can also make a plan that meets you requirement according to your site.

Working principle of coffee beans dryer:

The coffee beans heat pump dryer is a new type of dryer with high efficiency and energy-saving. Its working principle is based on the principle of reverse Carnot cycle, using a small amount of electric energy and compressor to evaporate the common substance into a gaseous state in the evaporator after passing through the expansion valve. It also absorbs a large amount of heat energy in the air. The gaseous working fluid is compressed by the compressor into a high-temperature, high-pressure gas, and then enters the condenser to release heat, and heats the drying medium. Such continuous heating can heat the drying medium to 40°C-- 85°C.

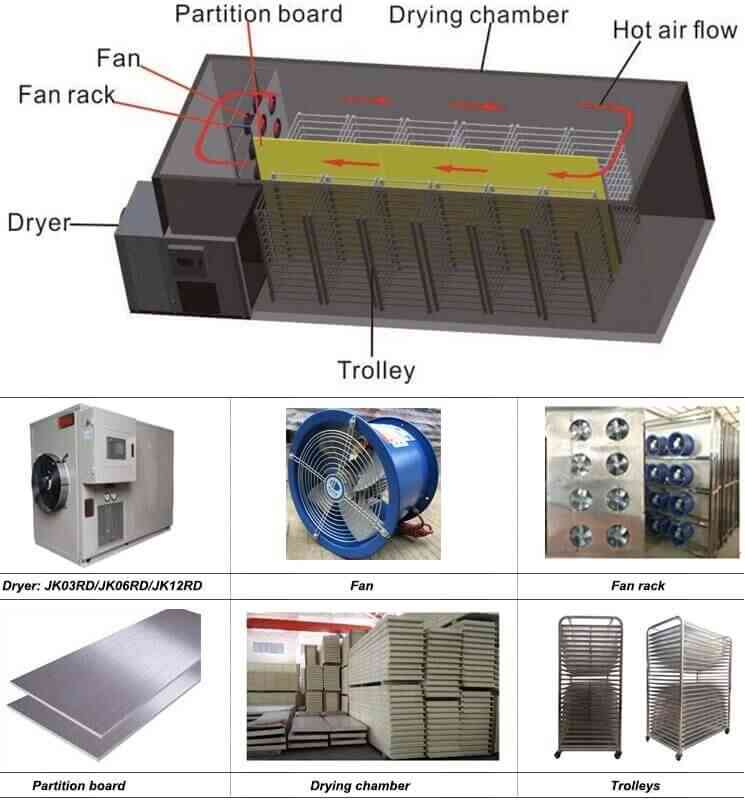

Component of coffee beans drying machine:

A. HostAir energy heat pump drying dehumidifier (heat pump dryer uses inputting little electric energy to absorb free heat in the air to dry materials)

B. Drying room

Polyurethane foam insulation warehouse (materials can be replaced), used to store materials. To a great extent, ensure that the heat of the drying room is not lost so that the drying room can heat up quickly.

C. Fan and fan rack

Bring the heat to every corner of the drying room to increase the temperature of the drying room, and take away the water evaporated from the material.

D. Trolleys and trays

Used to place materials, made of 304 stainless steel, corrosion-resistant, and long service life.

Advantages of coffee beans dryer:

1). Convenient installation: convenient installation and demolition, less floor space, and can be installed indoors and outdoors.2). High efficiency and energy saving: only a small amount of electrical energy is needed to absorb a large amount of heat in the air, and the power consumption is only 1/4 of that of an electric heater;

3). Environmental protection and pollution-free: without any combustion and emissions, it is a sustainable and environmentally friendly product.

4) Long service life, low maintenance cost: It is developed based on traditional air-conditioning technology with stable performance, reliability, and long service life; safe and reliable operation, automatic and manual operation, intelligent control.

Coffee beans drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.