How to Dry Cacao Beans/Dehydrate Cacao Beans in a Dehydrator

How to dry cacao beans?

Chocolate, originally called cacao beans, is a seed taken from the fruit of the cacao tree. This fruit that grows directly from the trunk and branches is also called a cocoa pod. The color of the mature cacao fruit, or cacao pod, changes from turquoise green to yellow-brown or brown-red. Different species of trees have different shapes, sizes, and colors. Split the pod, and you can see the cocoa beans wrapped in a white flocculent substance. Take out the beans to dry, and then roast them to form cocoa beans.The drying of cocoa beans is an important step in the processing of high-quality cocoa beans because there are still some reactions that can produce good flavor during the drying process. Ideally, fine cocoa should dry within 5 to 7 days. This allows the acid in the cocoa to volatilize, resulting in a low-acid, high-quality flavor product.

How to dry cacao beans in large quantity:

The drying method and drying time are different according to different methods and techniques adopted by different companies or manor. Two different methods are mainly used now: sun-drying or artificial drying. Sun drying is a common traditional practice, especially for small farmers, because it is much cheaper than manual drying. Cocoa beans are spread on leaf pads or concrete ground in a relatively thin layer, and then turned over or raked to dry evenly.

Henan Baixin company has various types of cocoa beans drying equipment, small movable ovens, large closed drying rooms, and fully automatic drying lines. Whether you are an individual user or an enterprise, we can provide suitable cocoa beans drying machines with models complete. Not only that, but we can also make a plan that meets you requirement according to your site.

Working principle of cocoa bean dryer

The cocoa bean heat pump dryer is a new type of dryer with high efficiency and energy-saving. Its working principle is based on the principle of reverse Carnot cycle, using a small amount of electric energy and compressor to evaporate the common substance into a gaseous state in the evaporator after passing through the expansion valve. It also absorbs a large amount of heat energy in the air. The gaseous working fluid is compressed by the compressor into a high-temperature, high-pressure gas, and then enters the condenser to release heat, and heats the drying medium. Such continuous heating can heat the drying medium to 40°C-- 85°C.

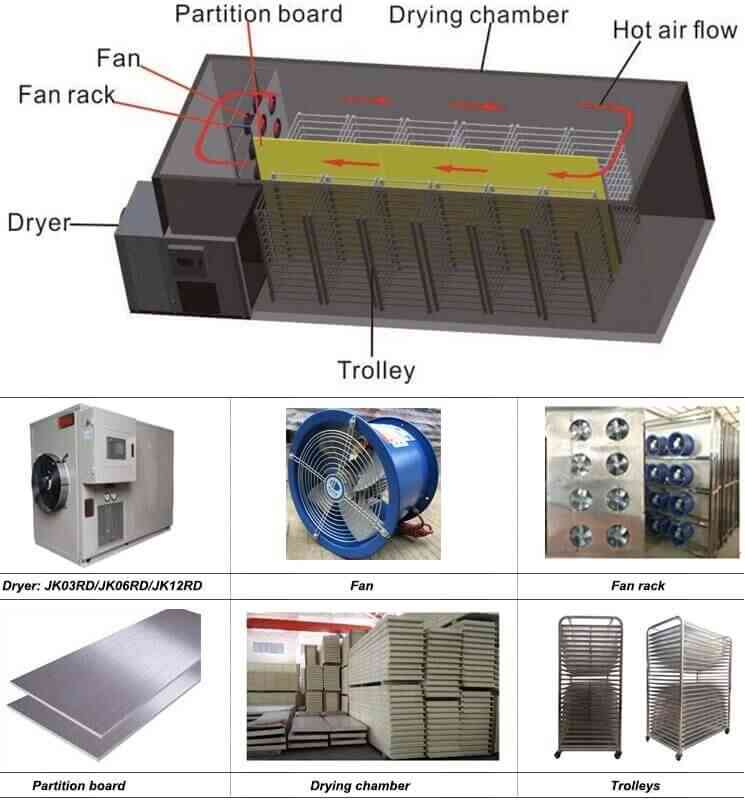

Component of cocoa bean drying machine:

A. HostAir energy heat pump drying dehumidifier (heat pump dryer uses inputting little electric energy to absorb free heat in the air to dry materials)

B. Drying room

Polyurethane foam insulation warehouse (materials can be replaced), used to store materials. To a great extent, ensure that the heat of the drying room is not lost so that the drying room can heat up quickly.

C. Fan and fan rack

Bring the heat to every corner of the drying room to increase the temperature of the drying room, and take away the water evaporated from the material.

D. Trolleys and trays

Used to place materials, made of 304 stainless steel, corrosion-resistant, and long service life.

Advantages of cocoa bean dryer

1). Convenient installation: convenient installation and demolition, less floor space, and can be installed indoors and outdoors.2). High efficiency and energy saving: only a small amount of electrical energy is needed to absorb a large amount of heat in the air, and the power consumption is only 1/4 of that of an electric heater;

3). Environmental protection and pollution-free: without any combustion and emissions, it is a sustainable and environmentally friendly product.

4) Long service life, low maintenance cost: It is developed based on traditional air-conditioning technology with stable performance, reliability, and long service life; safe and reliable operation, automatic and manual operation, intelligent control.

Cocoa bean drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.