How to Dehydrate Onion/Onion Drying Machine

Introduction of Drying Onion

Onion nutritional value is very high, is also a very nutritious vegetable, therefore, in peacetime many people love to eat onion. Whether eaten raw or cooked, there are many health benefits. But if we want to eat Onions, we must learn to choose Onions first. So, how do you pick Onions? First of all, when we buy Onions, we should pay attention to the drier, the better the onion skin, and the more tightly wrapped, the better. Secondly, we can see the texture of the onion from the surface. The skin is transparent with a tawny-colored texture. The ball of the onion is intact, without cracking or damage.There are two kinds of onion orange skin and purple skin, orange skin of the onion each layer is thicker, more water, more crisp taste; Purple skins contain less moisture and each layer is thinner. The yellow ones are sweeter and the purple ones are spicier. You can choose according to your own needs.

If you want to make dry Onions, use large and plump Onions.

How to use the dehydrator to dry Onions

- Slice and rinse. Use a knife to cut the tips of ripe Onions, dig out the roots, and peel off the onion coat, skin and scales until the inner layer is tender white or yellowish-white. Remove the damaged part, separate the onion by size and rinse once in clean water. Yq-1 onion directional slicing machine was used to cut the onion into rings with different diameters. The width of the onion slices was 4 ~ 4.5mm. Rinse with water as you cut, shaking out the overlapping wafers. When rinsing, put the scallion slices into a bamboo basket or a porous plastic basket in a running clear water pool, turn the scallion slices up and down with a slotted spoon, and generally rinse with clean water 3 times.

- Throw water and dry. After 30 seconds of centrifuge, take out the gauze together with the spring onion pieces and spread them on the drying screen. The mesh screen holes are generally 3mm×3mm or 5mm×5mm. Then install the drying screen on the drying truck rack. Before feeding, the dryer is preheated to 60℃ and the drying temperature is controlled at 58 ~ 60℃ for 6 ~ 7 hours. When the moisture content drops below 5%, a single tunnel or hot air dryer can produce 300 ~ 400kg dehydrated onion slices within 24 hours. Generally, 13 ~ 15 tons of raw materials, can produce 1 ton of dry products.

- Select. The selection process is divided into three stages. First, the shallots are moved into the separator to screen out debris and impurities, and then unqualified yellow, green, brown, heterochromatic, and impurities are picked out on the conveyor belt, and metal inclusions are removed. After one or two treatments, the onion slices are poured on a stainless steel table or non-toxic white plastic board and carefully selected. According to the quality standards of finished products, the onion slices are put into double-layer edible plastic bags.

The dehydrated vegetables that have been dried using the special mesh belt dryer from Baixin company have good color, low breakage rate, and high yield. The mesh speed, temperature, and humidity can be adjusted according to production needs to meet the drying treatment of dehydrated vegetables with different moisture content and different varieties.

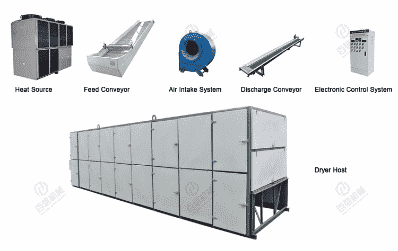

Composition of Onion Dryer

Baixin mesh belt type dehydrated Onion dryer is composed of 4 parts: feeding conveyor, drying system, heat source, and discharging conveyor.

Technical Data of Onion Dehydrator Machine

.png)

Onion drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.