How to Dehydrate Meat/How to Make Dried Meat

How To Make Dry Meat/How To Dehydrate Meat

Dried meat is made of fresh pork, beef or mutton and other ingredients through pre-cooking, recooking, baking and other processes. Because the shape of the finished meat is usually one centimeter square, it is called dried meat. Dried meat processed by traditional technology is a convenient meat food favored by people of all ethnic groups because of its unique flavor, rich nutrition, long storage period and convenient travel at home..jpeg)

How to make dried Meat at home?

- Cut the fresh beef into long strips about the size of your thumb.

- Put the cut beef into the container, add salt, aniseed, scallion, soy sauce and marinate for about 20 minutes. The amount of salt should be added according to personal needs.

- Will pickled beef jerky in a dry ventilated place cool air dry, can not be exposed to the hot sun, or it will deteriorate, about 15 hours of cool, that is, half of the water, it looks like the surface is wrinkled without water outflow is completed.

How to dry meat in large quantities?

Because people have a large demand for jerky, small-scale production can not meet the demand for jerky, so it is very important to use a dehydrator to make jerky.- First of all, the parts with tight meat and more lean parts, such as fresh beef leg meat as raw material, if frozen meat, should be placed in the thawing room to thaw, the temperature is slowly raised to 2℃ ~ 4℃, to facilitate the thawed raw meat should maintain normal color and quality. According to the processing requirements, the beef should be cut into meat pieces or strips, slices, and diced meat that are suitable for the production of meat jerky. The meat should not touch the water. The fascia should be removed before cutting.

- Then according to the taste demand, add a variety of seasoning, such as salt, soy sauce, sugar, five-spice powder, pepper powder, and so on. The seasoning should be stirred evenly to ensure full flavor. The processing plant generally chooses the beef pickling rolling kneading machine. The curing temperature was kept at 0℃ ~ 4℃. (According to the different taste, can be matched with different seasonings, achieve spiced, salty dry, original flavor, etc.)

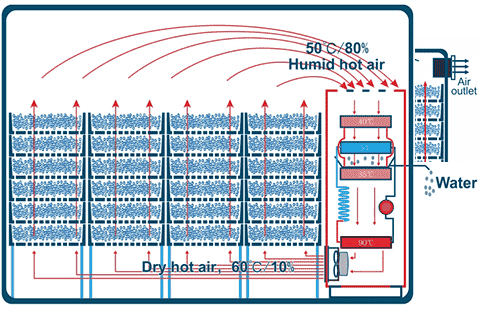

- The processed fresh meat strips are suspended in the new heat pump beef jerky drying room to choose the intelligent air drying mode. Note: the meat strips can not drip, should be hung straight, do not adhere to each other, the meat strips and the meat strips retain a little distance between them, to benefit ventilation and ventilation, dry evenly. As long as the air can heat pump type meat dryer, set up intelligent temperature and humidity control system. Generally in the temperature of 40℃-60℃, the temperature of about 60% indoor environment, 36 hours to dry a batch. At this time, you can see the color of the beef is dark red, and the hands feel dry and slightly hard. The dried raw meat can be directly packaged and stored in cold storage or can be cooked again, such as cooking and drying again. Recooked jerky shall be cooled to room temperature before packaging and sterilization and stored in a sanitary, ventilated, dry and cool warehouse.

Recommendation of meat dehydrator/drying machine

Drying essence is take moisture away, but takes away the moisture temperature is not the most critical factor. The key for drying is depending on relative humidity within certain space, Baixin Company took advantage of the dry essence, originality developed a "Closed Cycle" dryer, changed the traditional heat pump dryer "bake" to "dehumidifier”. Its several advantages were unmatched by the traditional heat pump dryer.Baixin meat dehydrator has a compact structure, great energy-saving, wide application, high drying quality, easy operation, simple installation and removable. it is the best drying equipment for small firms, drying experiment and scientific research. The users only connect the power to use, is the easiest operation heat pump dryer.

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.