How to Dehydrate Fig

How to dry figs:

Figs are rich in trace elements such as iron, calcium, and potassium, and their cellulose content exceeds that of most fruits and vegetables. Making dried figs can not only maintain the sweetness of figs but also extend its shelf life for several months. You can use the oven to dry figs. Set the temperature of the oven at 120-140 degrees Celsius. Turn it over frequently during the roasting process. After roasting, take it out and cool it down for storage. What’s more, you can also dry the figs directly in the sun or use a dryer to make dried figs in large quantities.

How to dry figs in the oven:

- Preheat the oven to 60℃. Choose the lowest heating temperature on the oven, because drying figs require a balanced, low-heat temperature environment. If the temperature is higher than 60℃, the figs are easily roasted. (If the minimum heating temperature of the oven exceeds 60℃, you need to open the oven door a bit during the drying process)

- Rinse the figs thoroughly with water, cut off the stalks and damaged parts of the figs, and soak up the water with a dish towel or kitchen paper towel.

- Cut the figs in half and place them on a cooling rack for the oven with the cut side up. A cooling rack with ventilation holes must be used here to ensure that the figs are dried evenly on the upper and lower sides. If you use an ordinary baking tray, the figs will not be dehydrated evenly.

- Figs need to be baked in the oven for 36 hours. Open the oven door slightly to help the moisture escape and prevent the figs from overheating, and instead of being roasted. If you don't want to keep the oven on, turn off the oven halfway through the baking process and turn it on again when needed. It should be noted that during the drying process, you must often turn the figs.

- Wait for the figs to cool completely before storing. When you break open the figs and you can’t see the juice, the figs are dried. Take the figs out of the oven, let them cool completely, put them in an airtight container or airtight preservation bag, and put the airtight container in the refrigerator to refrigerate or freeze. Dried figs can be frozen for three years, or refrigerated for several months.

How to dry figs in the sunshine:

- 1. Wash the ripe figs thoroughly.

- Rinse the figs with cold water to remove dust and dirt. Then use a kitchen paper towel or a dishtowel to gently soak up the water.

- 2. Cut the figs in half.

- Cutting the figs can shorten the drying process.

- 3. Place the figs on a metal grid or wooden shelf covered with gauze.

- Put the cut side up on the figs on the shelf. To dry the figs as soon as possible, the shelf must be ventilated up and down, so do not use tools with no mesh on the surface to dry the figs.

- 4. Cover the figs with gauze.

- This prevents the figs from being contaminated by bugs during the drying process. The edge of the gauze should be firmly tucked under the drying rack. If necessary, it can be fixed with tape to prevent the gauze from loosening.

- 5. Place the shelf in the sun for 2 to 3 days.

- Turn the figs every morning to make sure they get the sun on each side. When no juice comes out from the squeezed figs, the figs are dried.

- 6. Put the dried figs in an airtight container and put them in the refrigerator to refrigerate or freeze.

- The shelf life of refrigerated dried figs can reach several months, while the shelf life of frozen dried figs can even reach 3 years.

How to dehydrate fig in dehydrator:

- After cleaning the fresh figs, cut the figs for drying, or dry the whole fruit. The drying efficiency of the cut figs is fast, and the time is shortened by more than half compared with the whole fruit drying.

- When drying, the figs should be evenly spread in the sieve tray to avoid squeezing and blocking. Push the figs into the dryer and start to set the drying process.

- The first step is to set the drying temperature to 55 ℃ and the time to one hour, and the dehumidification will not start.

- The second step is to set the drying temperature to 60 ℃ and the time to eight hours. The dehumidification is turned on.

- The third step is to set the drying temperature to 65 ℃ and the drying time to 8 hours, and continuously increase the moisture discharge, which can be controlled in combination with the time.

- The fourth step is to set the drying temperature to 68 ℃ and the time to one hour. At this time, the relative humidity is controlled within 20%, the dryer can be turned off after completion.

- After drying, check the dryness of the dried figs, usually, 15-20% of the water content is enough. If it is too dry, it needs to be softened, so that it will not affect the taste of the dried figs.

Tips:

- If you want to increase the sweetness of figs before drying, you can add 200 grams of sugar to 710 milliliters of water, and then bring the sugar water to a boil. After the water is boiled, pour the figs and simmer for about 10 minutes. Then remove the figs from the water and dry them according to the method introduced.

- Each 1 kg of fresh figs can be processed into approximately 330 grams of dried fruit. `

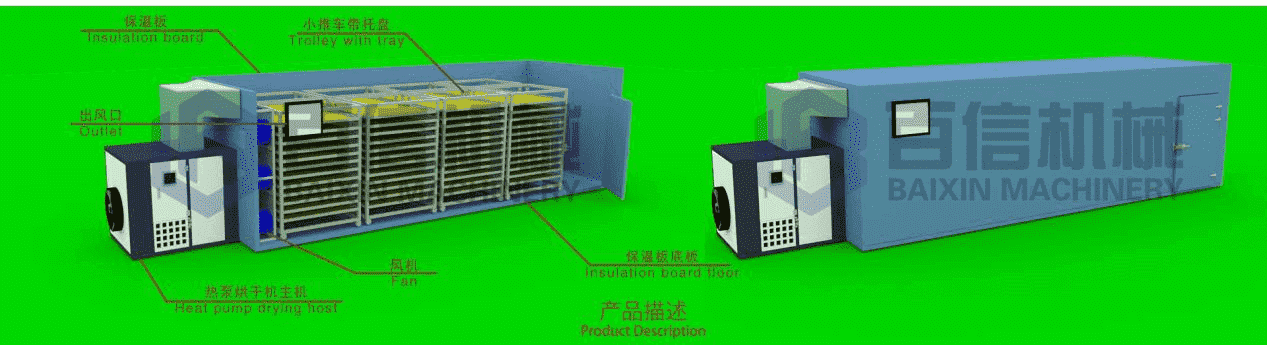

Heat pump drying machine use the principle of inverse Carnot cycle. It absorbs low-temperature heat energy in the air, which becomes high-temperature heat energy after efficient heat collection and integration by the heat pump system, and is transported to the drying room for cyclic heating and drying of materials.It refers to exhausting the hot and humid air in the drying room directly to the outside of the drying room through dehumidification device, and then replenishing natural fresh air.

Hot air circle drying machine belongs to high temperature heat pump unit. Its working principle is: the working fluid of the heat pump is compressed by the compressor, becomes high temperature and high pressure gas, enters the condenser, condenses and liquefies the heat, and is used for air heating in the drying room. The moisture in the material is vaporized and evaporated by the form of hot air, and the evaporated water vapor is discharged by the moisture discharge system, thereby achieving the purpose of drying the drying material.

Fig drying video:

Previous post:

Next post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.