How to Dry Beans Quickly/Dehydrate Beans in a Dehydrator

Why to dry beans quickly?

- Avoid mildew and prolong storage time. When the seeds are dried in the sun and the free water is almost exhausted, the life activity of the seeds is stopped, but the protoplasm structure of the embryonic cells is not destroyed and the cells have not lost their activity. If the seeds are not dried in the sun, they will breathe, consume the organic matter stored in the seeds, and maybe be produced by aerobic respiration and the reaction of substances in the environment and moldy, thus shortening the storage life of the seeds.

- Pest control. Grain moisture drops below 8%, and the worms can’t survive.

How to dry beans at home?

There are two ways to dry beans, the microwave oven heating drying method, and the natural drying method.

- The first microwave oven drying process steps are as follows:

- Put the beans in a container and wash them with tap water. Dry the beans in a filtered basket and preheat the oven to 160 degrees for 10 minutes.

- Place the beans in the oven on a tin foil-lined baking sheet and turn them twice in 20 minutes. (According to the different types of oven baking time difference. )

- Such as soybean golden skin crack will be baked, take out the baking tray, put in the ventilation place a little cool for a while.

- Take the container and load it.

The second natural drying process is as follows:

- Soak the beans in boiling water for half a minute, stirring as you soak.

- Remove soybeans from boiling water and place them directly in cold water.

- After pulling them out of cold water, dry them in the Sun.

- Store dried beans in a well-sealed container with cloves of garlic to prevent insects.

How to dry beans in large quantities?

Soybeans are dried in a variety of ways. Generally speaking, they are dried more naturally in the sun, because the harvest season for soybeans is usually late summer or autumn when there is usually more sunny days and less rainfall, so there is a chance for them to dry naturally, however, it takes longer for soybeans to dry naturally, and the degree of drying is not completely the same. If the amount is large, plus the harvest season is overcast and rainy, you can use the heating drying method. Even the use of professional drying equipment for drying, drying speed, and drying degree is consistent, and not affected by the weather.The soybean drying process is not complicated, cooking out color reduction, full shape only need a few steps:

Before drying, you can use pot boiling water or steaming cage again, so that the soybean is soft, for the later color paves the way, and then into the drying room for drying.

- Stage 1: set the temperature to 40 degrees and dry for 5 hours. So that most of the water out of the soybean, color, and shape of the initial shape.

- Stage 2: Temperature rises to 55 degrees, drying for 5 hours. Raise the temperature just a little bit, drain the water again.

- Stage 3: Heat up to 60 degrees and dry for 5 hours. The color and shape have been fixed, just need to remove the remaining moisture.

- Stage 4: heat up to 65 degrees and dry for 3 hours. Thoroughly eliminate moisture to achieve the effect of drying.

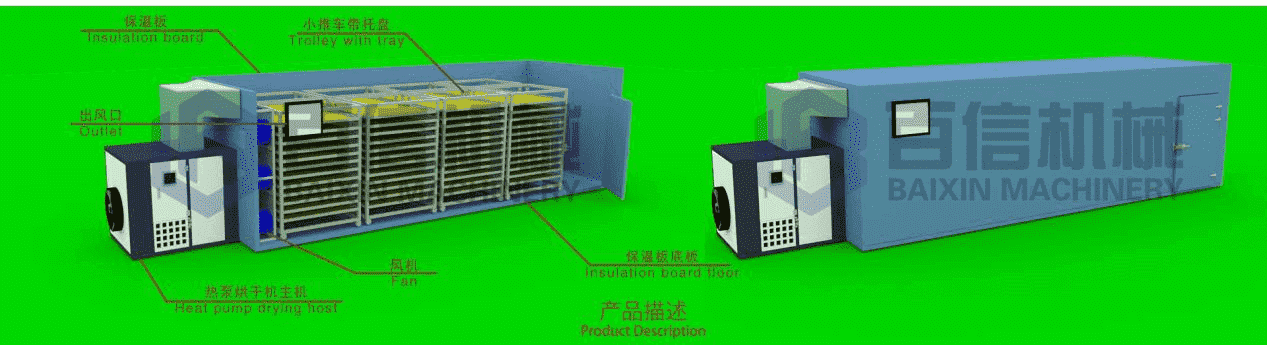

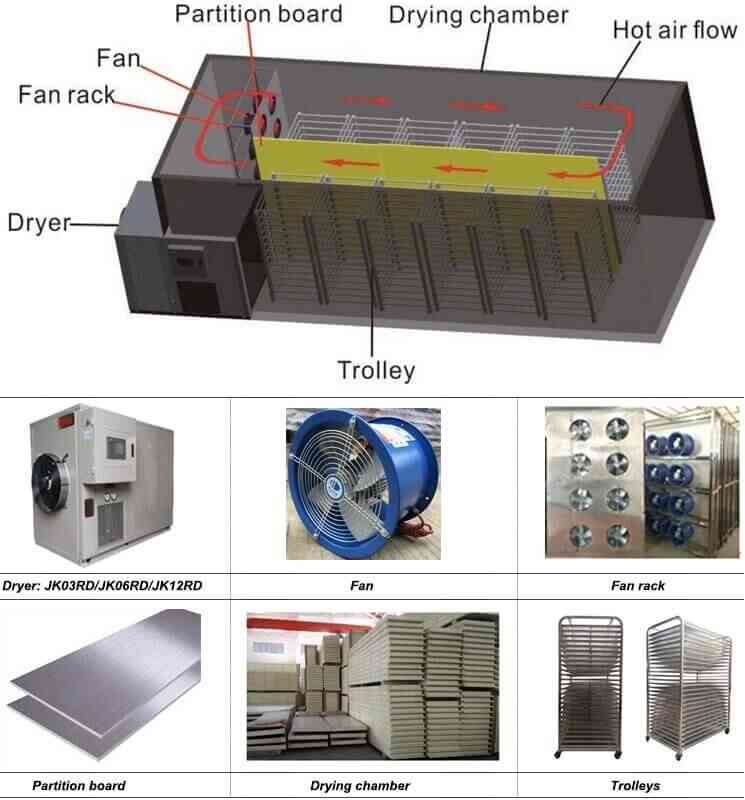

The principle of beans dryer machine working:

Baixin air energy heat pump dryer uses the reverse Carnot principle. The refrigerant is compressed by the compressor to become high-temperature and high-pressure gas, enters into the heat exchanger through the pipeline, and then passes through the fan to remove the heat generated by the heat exchanger send it to the drying room to heat and dry the seafood products and other materials, so that the seafood products are dried, and the moisture is discharged from the moisture outlet. The dehumidification system has a heat recovery device, and the recovered heat is used to heat the fresh air, which can save 60%-70% of the fresh air preheating energy consumption.

The beans heat pump dryer machine structure:

Beans drying video:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.