What are the Types of Dehydrator Dryers/Household Commercial Industrial Dehydrator Dryer

Why we need the dryer:

In recent years, with the continuous development of the social economy, the living standards of the people from the world have also been improved continuously, and dryers have appeared in everyone's lives in various forms. Today Henan Baixin company as the professional manufacture of dryer will introduce the varies of dryer for your reference.What are the types of dryer:

Previously, dryers were divided into two types, household and industrial. Industrial dryers are generally called dryers or drying equipment, which can be subdivided into many types. A household dryer generally refers to a machine that dries clothes. Now, due to different uses, commercial dryers are available, which are generally used by individual merchants or small and micro enterprises to process food or other items in small batches.There are some type in the following:

1. Exhaust fan typeThe exhaust fan type is similar to a large fan. Heat sources include electric heating, coal heating, gas heating, wood-fire heating, diesel heating. Both use heaters to heat the indoor space. The hot air passes through the materials and turns into moisture, which is directly discharged outdoors. This type of dryer can sustain high-temperature heat for a long time, so the drying temperature can reach about 80%, it can be with high capacity. To prevent the exhausting moisture from making the room wet, the exhaust pipe must be wiped.

2. Condensing

This kind of air is heated by electric heaters and there is a certain difference between the exhaust fan type. This general humidity cannot be discharged directly, but the water is decomposed through the condenser, and the excess water is recovered in the water storage tray. Or it can be discharged directly through the drain pipe. Its drying temperature is lower and the noise is lower, but it is more expensive in terms of price.

3. Heat pump type

The difference between the heat pump type and the above two types is that the heat pump compression generates more heat, and the drying temperature of the heat pump type is lower, and the temperature is at most about 80 degrees. It can be suitable for most of the vegetable. It is very energy-efficient, but the only thing is that it is more expensive.

In summary, compared with exhaust fan type dryers, condensing dryers have better effects to keep the original material taste, color, and the drying temperature is not high, which will also play a certain role in protecting nutrition of material. The heat pump dryer is more energy-efficient, energy-saving is about 60%, and it can protect material better than the condensing type. If you want to dry food, you can choose an air source heat pump dryer, which saves more than 20% of energy and has stable and reliable performance. It just caters to the current social development trend "energy saving, environmental protection, low carbon and green", which can save customers a lot of operating costs and maintenance costs.

Henan Baixin Machinery Equipment Co., Ltd is an export enterprise integrating equipment development, manufacturing, and operation services. It is a research and development and production base of drying equipment and food equipment in Central China. Products are exported to more than 90 regions in the world and are well-known Customers love.

We provide drying solutions for various industries:

-- Agricultural products drying and processing-- Herbal and spice drying and processing

-- Drying of food and seafood

-- Drying of industrial products and derivatives

The main drying machine we produce are:

-- Continuous mesh belt drying machine-- Heat pump drying machine

-- Microwave drying machine

-- Freezing drying machine

Baixin Machinery has more than ten years of industry experience and has mature solutions for a variety of materials. Welcome to bring materials to test the machine.

Household Commercial All-in-one drying equipment without installation for any material

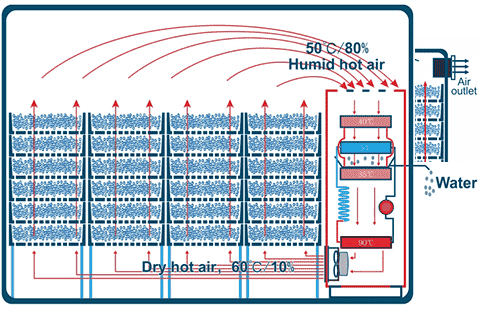

Drying essence is take moisture away, but takes away the moisture temperature is not the most critical factor. The key for drying is depending on relative humidity within certain space, Baixin Company took advantage of the dry essence, originality developed a "Closed Cycle" dryer, changed the traditional heat pump dryer "bake" to "dehumidifier”. Its several advantages were unmatched by the traditional heat pump dryer.

Baixin Food Dehydrator has a compact structure, great energy-saving, wide application, high drying quality, easy operation, simple installation and removable. it is the best drying equipment for small firms, drying experiment and scientific research. The users only connect the power to use, is the easiest operation heat pump dryer.

Large amount of dehydration 200-5000kg/h industrial drying machine continuous automatic work easy operation

industrial dryer machine is a kind of continuous production drying equipment, the main heating way has electric heating, steam heating, hot air heating. Its main working principle is to spread the material evenly in the network. The material is moved in the dryer by the operation of the machine, and the hot air draws out the water vapor of the material. so as to achieve the purpose of drying.

The operation temperature is 40-120 degree centigrade. And the dry cycle is 1-5 hours.

Household commercial industrial drying video:

Previous post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.