What is garlic drying steps and process/Garlic processing line

What is garlic drying steps and process/Garlic processing line

Garlic is also called rocambole, single garlic. Garlic is the general name of the garlic plant. Semi-annual herb, Allium, Liliaceae, used as medicine by bulbs. Harvest in spring and summer. When garlic is picked in June, the silt is removed, ventilated, and dried or baked until the skin is dry.Garlic is flat spherical or short conical, with gray or light brown membranous scales on the outside. The scaled leaves are stripped. There are 6-10 cloves of garlic, surrounding the round flower stems with the most fibrous roots. The outer membrane of each garlic clove is peeled off, white, thick, juicy scales are showed. There is strong garlic, spicy taste. It has a pungent smell and can be eaten or used for flavoring, and can also be used as a medicine. Underground bulbs are divided into purple and white according to skin color. After artificial cultivation and breeding, garlic has anti-cancer effects and is very popular among the public.

1.Choose garlic:

First remove the scarred, soft, rotten and shriveled garlic, and choose garlic that have a firm feel, complete garlic cloves, full grains, and white garlic flesh. In the selection process, too small garlic should be removed because if the garlic is too small. after the slicing process, the area of the garlic slice is too small that will affects the quality of the finished product.

2.Splitting the garlic

The principle and structure of the garlic splitting machine, through the flexible squeezing between the silicone flat plate and the upper silicone tapered disk, simulates the manual splitting principle and realizes the garlic splitting. There is a pressure buffer function between the silicone flat plate and the silicone tapered plate, which will not hurt the garlic but also can obtain the splitting effect, and the splitting rate can reach more than 95%.

3.Peeling the garlic:

Garlic has a pungent taste, so can not peel large quantities of garlic by hand. Use a garlic peeling machine to peel garlic in batches. The garlic cloves are naturally peeled without damage.

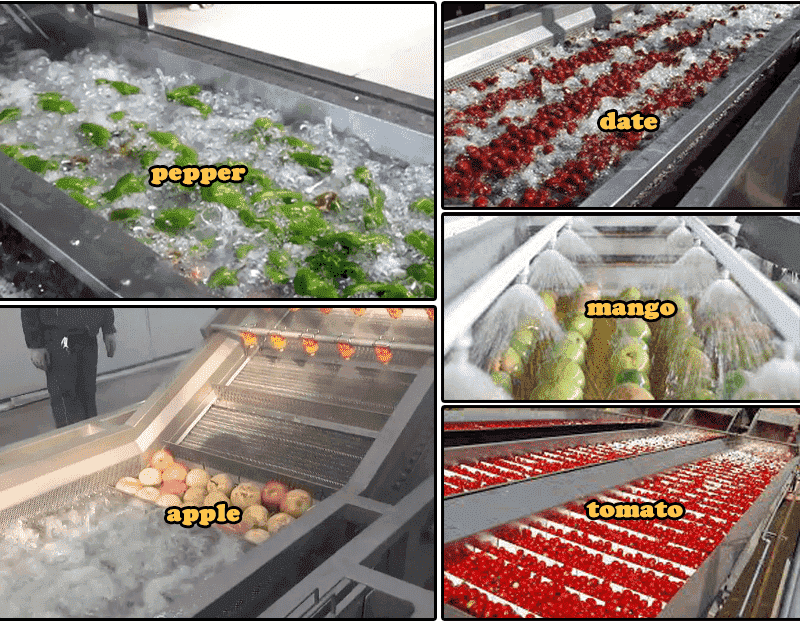

4.Washing the garlic

For the peeled garlic cloves after choosing, there will be dirt and dust attached to them inevitably. Before dehydration, these garlic cloves must be thoroughly cleaned. The washing machine is equipped with a bubble generating device to make the material rolling and remove the pesticide residue on the product surface. At the same time, an appropriate amount of medicament can be added for disinfection and fixation. Floating matter can overflow from the overflow tank, and the sediment is discharged from the sewage outlet to achieve the purpose of cleaning. It has the characteristics of high cleaning, energy-saving, water saving, stable and reliable equipment, etc.

5.Slicing the garlic

Garlic slicer is suitable for slicing garlic, and can also be used for slicing root vegetables (white radish, carrots, potatoes, sweet potatoes, etc.). It is an ideal equipment for vegetable processing in the vegetable processing industry; the machine uses a rotating cutter, suitable for dry slicing of garlic and cut root vegetables into slices. It does not need to be washed with water during the garlic slicing process, Which saves water resources and avoids environmental pollution; the peeled garlic granules have a better slicing effect. It has the characteristics of convenient operation, low energy consumption, sanitation, safety, and high efficiency.

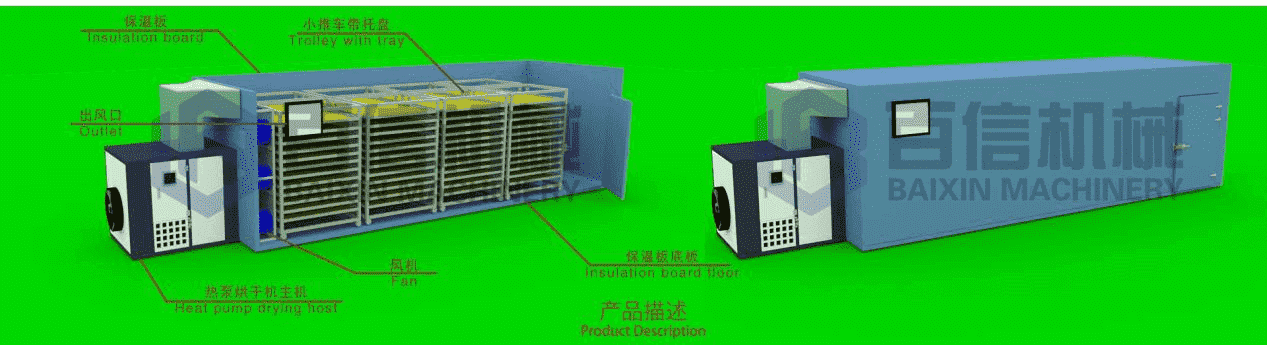

6.Drying the garlic

The garlic slicer are dried by a heat pump dryer. The specific method is: evenly sprinkle the garlic slices on the tray of the dryer, insert the tray into the material truck, and then push the material truck into the drying room, and turn on the host. During the drying process, the temperature should be controlled between 55°C and 75°C, and the drying time should be 10-12 hours. The standard for dried garlic slices is: the slice shape is normal, the color is white, and the moisture content is 4-5%.

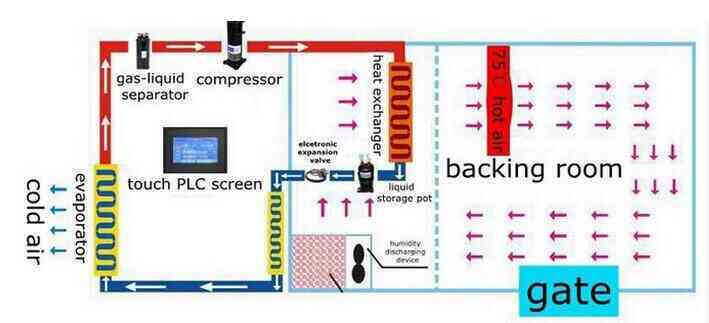

Commercial 100-3000kg/h large amount of dehydration wide application and easy operation

Heat pump drying machine use the principle of inverse Carnot cycle. It absorbs low-temperature heat energy in the air, which becomes high-temperature heat energy after efficient heat collection and integration by the heat pump system, and is transported to the drying room for cyclic heating and drying of materials.It refers to exhausting the hot and humid air in the drying room directly to the outside of the drying room through dehumidification device, and then replenishing natural fresh air.Hot air circle drying machine belongs to high temperature heat pump unit. Its working principle is: the working fluid of the heat pump is compressed by the compressor, becomes high temperature and high pressure gas, enters the condenser, condenses and liquefies the heat, and is used for air heating in the drying room. The moisture in the material is vaporized and evaporated by the form of hot air, and the evaporated water vapor is discharged by the moisture discharge system, thereby achieving the purpose of drying the drying material.

Advantage of heat pump garlic dehydrator/drying machine

The heat pump drying machine is Commercial All-in-one universal drying equipment without installation, suitable for 85% of food vegetable fruit mature material. This kind of dryer has the advantages of easy operation low cost clean and sanitary small area occupy.

1:Applicable:Vegetable,fruit,meat,seafood,agricultural ,noodle,wooden

2:Output:100-3000kg/h

3:Heat pump model:1P/2P/3P/6P/8P/10P/15P/20P/30P/40P/60P

4:Drying time: Depends on different drying materials

5:Core advantages: Energy saving and environmental protection, simple or without installation, easy operation, wide application for food vegetable fruit dryer,small area occupied

Garlic drying video:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.