French Fries Production Line

French Fries Production Line

French fries are a kind of food made from potatoes, cut into strips and then fried, originated in Belgium. As one of the most common fast food, it is popular all over the world. People usually eat fries at lunch or dinner, but also as a snack. French fries are available in restaurants, fast food restaurants and bars.French fries have a significant market in the food industry, and the demand for french fries is increasing, so if you want to mass-produce french fries, you will need a french fries production line. So, what machinery does a complete french fries production line include? Next, I will share with you two french fries production lines, one is a large-volume automatic frozen french fries production line, and the other is a small-scale, semi-automatic french fries production line.

French Fries Production Line

This set of production lines is a new type of french fries production line developed and developed by our company. This production line is made of high quality 304 Stainless Steel. PLC electrical control, safe and efficient.The production line adopts advanced technology, the output is high, and the ex-factory price is directly sold. This is the best choice for businesses and the most ideal device. Next, I will introduce the details of these two french fries line to you respectively.Full Automatic Frozen French Fries Production Line

This french fries production line can be fully automated, and continuous frying can control the frying speed and temperature, which can increase the production of french fries while also managing the cost of labor.

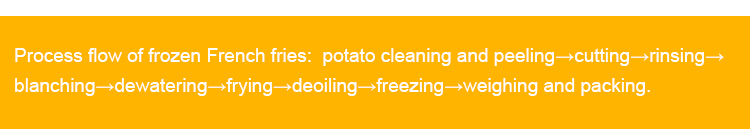

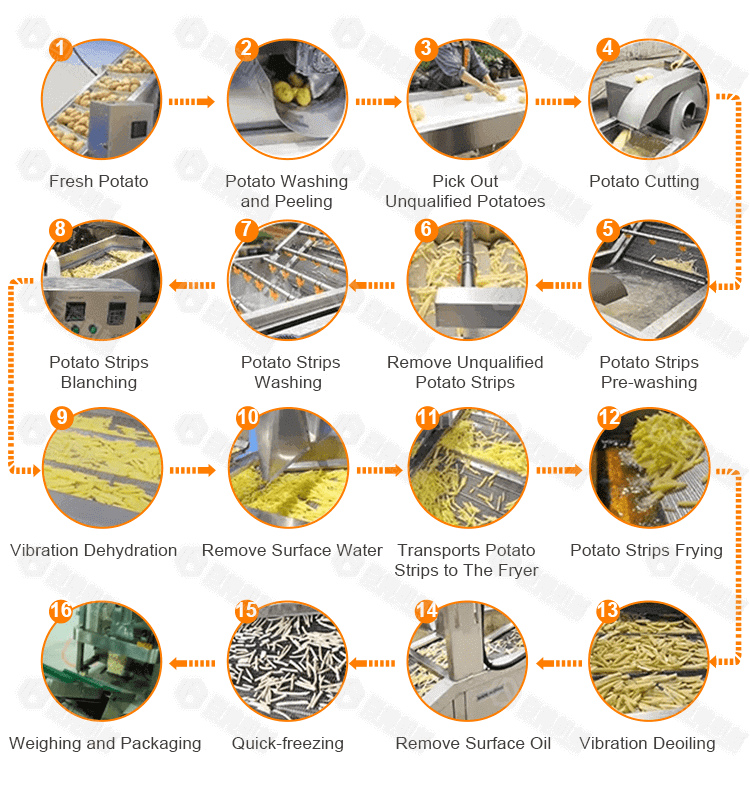

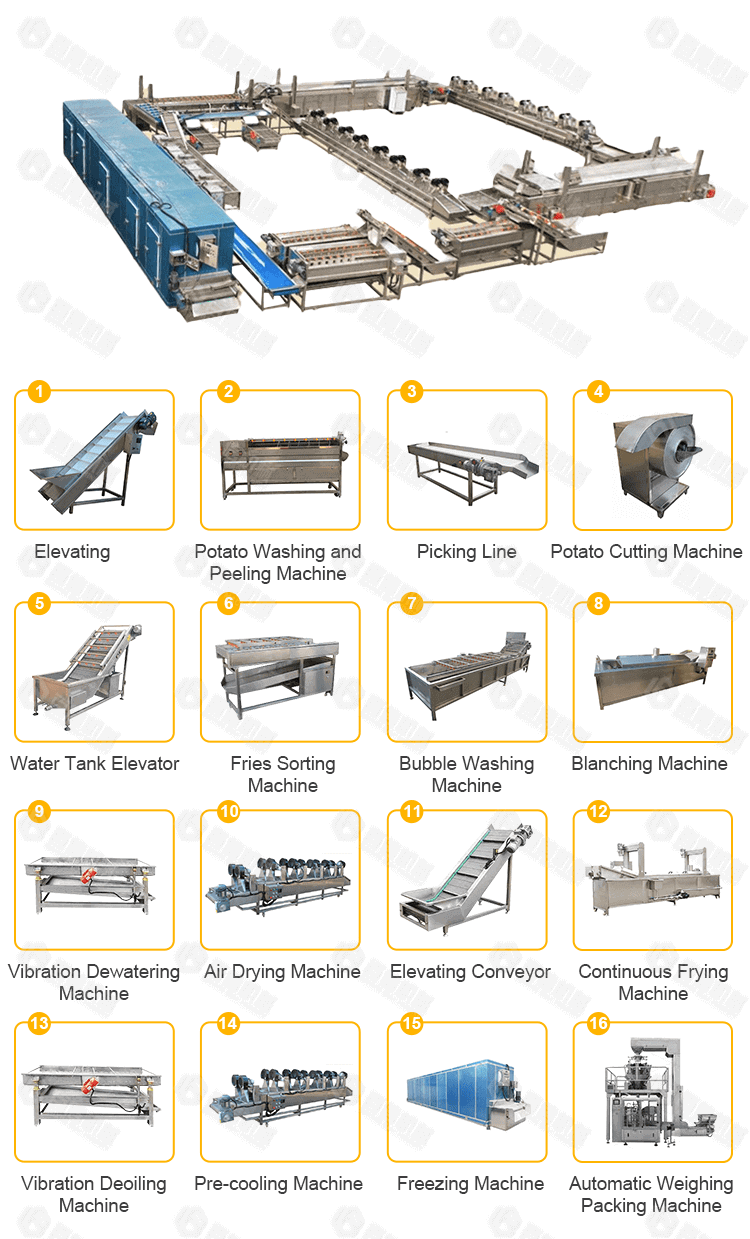

French fries flow chart:

A fully processing of french fries is potato cleaning and peeling-pick ot unqualified potatoes-potato cutting-potato strips pre-washing-remove unqualifies potato strips-potato strips washing-potato strips blanching-vibration dehydration-remove suface water-transports potato strips to the fryer-potato strips frying-vibration deoiling-remove suface oil-quick freezing-weighing and packaging

Components of fully automatic frozen french fries machine

A fully automatic frozen french fries machine contains: elevating, potato washing and peeling machine, picking machine, potato cutting machine, water tank elevator,fries sorting machine, bubble washing machine, blanching machine, vibration dewatering machine,air drying machine, elevating conveyor, continuous frying machine, vibration deoiling machine, pre-cooling machine, freezing machine and automatic weighing packing machine.

| No. | Machine Name | Function | Advantage |

| 1 | Elevating | For elevating and conveying potatoes into the next washing peeling machine | 1.The size can be customized 2.Conveying speed adjustable. |

| 2 | Potato Washing and Peeling Machine | Thoroughly washing and peeling the potatoes | 1. Washing and peeling capacity can be customized. 2. The length of brush can be customized. 3.We use high quality brusher,even old potatoes that are hard to peel can be peeled well. 4.Spraying system to clean the potatoes. 5.Spiral design to make sure automatic discharging. 6. The discharge speed can be adjusted. 7. The whole machine is made of 304 stainless steel. |

| 3 | Picking Line | For manually disposing the uncleaned places and selecting the defective potatoes | 1.Picking table size can be customized 2.Conveying speed adjustable. |

| 4 | Potato Cutting Machine | Cutting the potatoes into fries, sizes adjustable from 7*7 to 12*12mm | 1. The strips' size such as 7*7mm, 8*8mm, 10*10mm and custom made can be changed by adjusting the blade. 2.Cutting surface is smooth without damage. 3.The whole machine is made of 304 stainless steel, High speed stainless steel blades. |

| 5 | Water Tank Elevator | water as buffer to prevent fries breakage, and simply removing starch, meanwhile elevating fries into next step | 1.Conveying speed adjustable. 2.The whole machine is made of 304 stainless steel. |

| 6 | Fries Sorting Machine | Automatically picking up the small pieces fries | 1.Remove the unqualified fries. 2.The screening speed is fast and the quality of French fries is high. |

| 7 | Bubble Washing Machine | Through high pressure waterflow and water bubbles to impact and scrub the fries to wash off the starch | 1.Remove the starch from the potato chips. 2.Strong water flow, bubble impact. 3.High pressure spraying system. 4.Filter system and water recycling system. |

| 8 | Blanching Machine | Through 60-95 degree hot water blanching to inhibit the activity of the enzyme and maintains the original vivid color of the fries | 1.You can use gas, electricity or diesel as power for this machine depending on your needs. 2.It can effectively protect original vivid color of the potato strips/potato chip. 3.You can add additives during blanching process. |

| 9 | Vibration Dewatering Machine | Through vibration to remove the surface water and also to transport the fries uniformly to the next machine | The de-water time is adjustable. |

| 10 | Air Drying Machine | Through high pressure wind blowing for pre-cooling and removing the excess water in short time, effectively prevent the fried oil jumped phenomenon | 1.The multi-layer mesh belt conveyor belt and special fan outlet completely remove the moisture on the surface of the french fries. 2.Fan can be adjusted up and down. |

| 11 | Elevating Conveyor | For elevating and conveying the fries into next fryer machine | 1.The size can be customized 2.Conveying speed adjustable. |

| 12 | Continuous Frying Machine | For quick frying the fries around 40 seconds in 180°oil to avoid the adhesion and extend the shelf life | 1.Automatic lifting system, easy to clean. 2.Double mesh belt transmission to avoid the chips floating. 3.Oil filter and recycling system to automatically and continuously filter the oil residue to extend the service life. 4.Electric or gas heating. |

| 13 | Vibration Deoiling Machine | Through high frequency vibrating to achieve deoiling purpose, and also to convey the fries uniformly to next machine | The de-oil time is adjustable. |

| 14 | Pre-cooling Machine | Through high pressure wind blowing for pre-cooling and deoiling the fries | 1.The multi-layer mesh belt conveyor belt and special fan outlet completely remove the oil on the surface of the french fries. 2.Fan can be adjusted up and down. |

| 15 | Freezing Machine | Through mechanical vibration and wind pressure, the fluidized quick freezer floats products on stainless steel mesh belt, frozen products and prevent adhesion, achieve IQF | Customized according to customer needs |

| 16 | Automatic Weighing Packing Machine | For packing the finished frozen french fries | It can fill Nitrogen automatically, automatic weighing, automatic sealing and automatic packing. |

Fully automatic frozen french fries production line technical parameters

| Frozen French Fries Production Line | ||||

| No. | Machine Name | Powder | Size | Price(Dollar) |

| 1 | Elevating | 0.55kw | 2400*700*1600mm | 1850 |

| 2 | Potato Washing and Peeling Machine | 4.37kw | 3400*900*1400mm | 6900 |

| 3 | Picking Line | 0.75kw | 3500*700*900mm | 2150 |

| 4 | Potato Cutting Machine | 1.1kw | 950*800*950mm | 1230 |

| 5 | Water Tank Elevator | 0.75kw | 2200*800*1600mm | 2800 |

| 6 | Fries Sorting Machine | 2.2kw | 2000*1100*1400mm | 3000 |

| 7 | Bubble Washing Machine | 6.6kw | 3500x1200x1300mm | 5380 |

| 8 | Blanching Machine | 120KW | 4500x1200x1300mm | 7000 |

| 9 | Vibration Dewatering Machine | 0.5kw | 1800*1000*1300mm | 2770 |

| 10 | Air Drying Machine | 7.1kw | 3500x1000x1600mm | 4600 |

| 11 | Elevating Conveyor | 0.55kw | 2000x800x1300mm | 1380 |

| 12 | Continuous Frying Machine | 120kw | 4000x1100x2200mm | 10500 |

| 13 | Vibration Deoiling Machine | 0.5kw | 1800*1000*1300mm | 2770 |

| 14 | Pre-cooling Machine | 7.1kw | 3500x1000x1600mm | 4600 |

| 15 | Freezing Machine | 25kw | 7100*3300*3000 | 38500 |

| 16 | Automatic Weighing Packing Machine | 6kw | 3500*2700*3600 | 21500 |

| Support customization according to customer requirements. | 116930 | |||

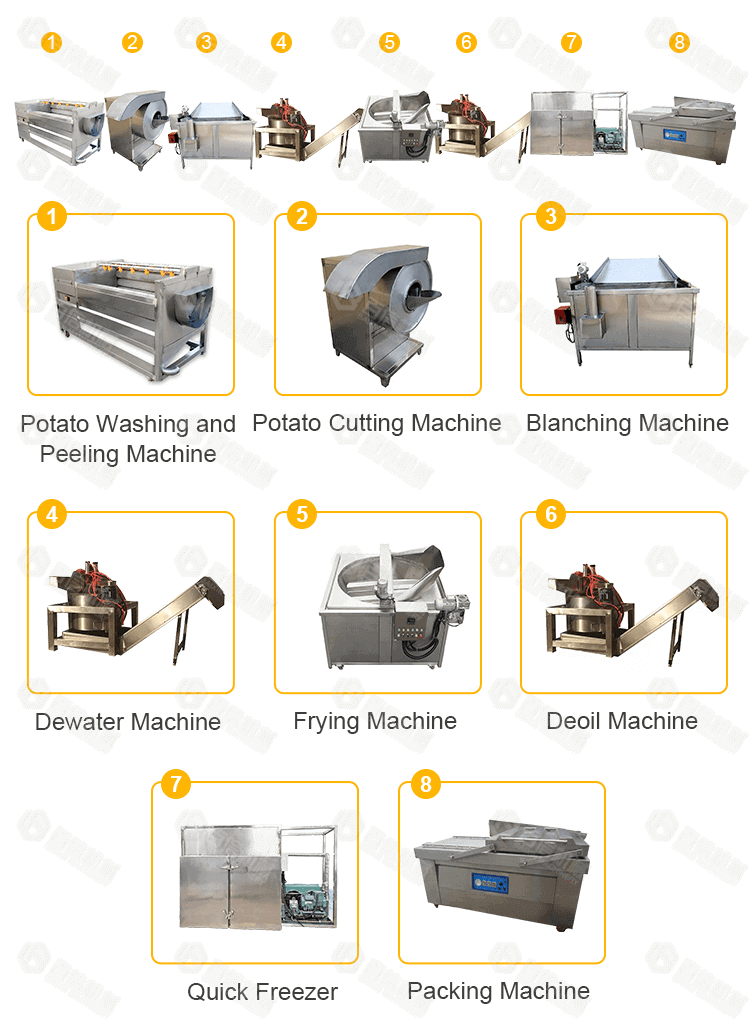

Semi-automatic French Fries Production Line

Components of semi-automatic French Fries Production Line

A semi-automatic french fries machine contains: potato washing and peeling machine, potato cutting machine, blanching machine, dewater machine, frying machine, deoil machine, quick freezer and packing machine.

Semi-automatic french fries processing machine technical parameters

| 200-300kg French Fries Production Line | ||||

| No. | Machine Name | Powder | Size | Price(Dollar) |

| 1 | Potato Washing and Peeling Machine | 3.37kw | 2300*700*1400 | 4300 |

| 2 | Potato Cutting Machine | 1.5kw | 750*500*1100 | 1230 |

| 3 | Blanching Machine | 40kw | 1200*700*950 | 3300 |

| 4 | Dewater Machine | 1.1kw | 1000*500*700 | 1400 |

| 5 | Frying Machine | 40kw | 1200*700*950 | 3300 |

| 6 | Deoil Machine | 1.1kw | 1000*500*700 | 1400 |

| 7 | Seasoning Machine | 1.5kw | 1000*800*1300 | 1880 |

| 8 | Packing Machine | 3kw | 1300*700*1450 | 2600 |

| Support customization according to customer requirements. | 19210 | |||

The advantages of french fries production line

1.Processing flow can be customized: Different machines for making potato chips or frozen potato fries.Different machines for semi automatic or fully automatic processing.2. Process capacity: Output capacity available from 30kg/h, 50kg/h, to 100kg/h, 300kg/h, to 1000kg/h, 2000kg/h

3. Material: All equipment are made of food grade SUS304 stainless steel.

4. Heating method: Electric, gas, or diesel heating source for blanching and frying machine.

5. The size of potato fries and the thickness of potato chips are adjustable

6. For potato fries line, we have special equipment to remove the unqualified fries.

The above are the two french fries production lines shared by baixin machinery. Do you want to join french fries business? If you are interested in french fries production line or have questions about the french fries production line, please feel free to consult us.

French fries production line video:

Previous post:

Next post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.