How to Dehydrate Tomatoes

How to Dehydrate Tomatoes:

Tomatoes have well-developed roots, wide and deep distribution, strong rooting ability, easy to grow adventitious roots in stems, easy to transplant, and feasible to propagate by cutting. It is an indispensable delicacy in people's daily life. It can not only supplement a lot of elements needed by the human body but also make salads for people to taste.Benefits: Slow down color spots, delay aging, resist cancer, prevent gingival bleeding, enhance resistance, strengthen the stomach and promote digestion.

Dried tomato is a kind of red dried fruit food, which is a leisure snack obtained by people using fresh tomatoes as the main raw material after drying, processing, or baking. This kind of food is full of toughness, sweet, and slightly sour. People can kill time and absorb rich nutrition when eating it. Regular consumption can also protect their beauty.

How to Dehydrate Tomatoes at Home:

1.Wash small tomatoes and soak them in light saltwater for about 10 minutes.

2.Wash tomatoes with a dry cloth to wipe off the surface moisture.

3.Cut 4 flaps with a knife. It is best to use a ceramic knife, so the cut part is not easy to oxidize.

4.Put it out, put it in a basket with its skin down, and expose it to the sun. (Dry tomatoes must be dried in sunny weather. One day's drying is enough. If the weather is bad, it is easy to mildew and become sticky in the drying process, and spoiled foods must not be used.)

5.Collect in the house at night and sprinkle salt evenly.

6.The next day, the dried tomatoes will be dried, and some of them can be used to mix salads, mix noodles, make Italian pizza and bread. The rest can be stored in a sealed management refrigerator.

How to dehydrate tomatoes in a dehydrator:

Material selection-peeling-squeezing juice-hardening-washing-candied-candied-drying-finished product.1. Choose fruits with thick meat, less juice, full red color, and not ripe, and reject unqualified fruits with insufficient maturity, diseases, and insect pests, and bad damage. Peel. Pre-cook the washed tomato fruit in boiling water for about 1 minute, immediately cool it, and peel off the peel of the tomato.

2. Preheat tomatoes in boiling water for 1 minute, cool them immediately, and peel them off. Dig the pedicle and sew at the stem, and squeeze out the juice gently.

3. Soak the fruit blank in 0.30% calcium chloride solution for 2 hours.

4. Wash the hardened fruit embryo with clear water, remove the fruit embryo, and drain the water.

5. Drain the tomato embryo, soak it in 30% sugar solution for about 24 hours, and add 0.30% citric acid to the sugar solution.

6 . Pour the sugar-stained tomatoes together with the soaking solution into a jacketed pot, slowly heat up to boiling, and after about half an hour, soak the tomato juice and the boiled sugar solution in a porcelain jar for 12-24 hours. Soak 2-3 times, and increase the sugar concentration every time. Stop the fire when the concentration of the boiled sugar solution reaches 65%, pour it into the porcelain jar for 8-10 hours, then fish out the tomato fruit and drain the sugar solution.

7. Put the tomato fruit drained of a sugar solution into the material tray, insert the material tray into the material cart, dry it at 60℃-65℃, set the drying time for 15-20 hours, and continuously drain the moisture until the water content reaches about 18% and the soluble solid content reaches 70%.

Recommendation of tomatoes dehydrator/drying machine

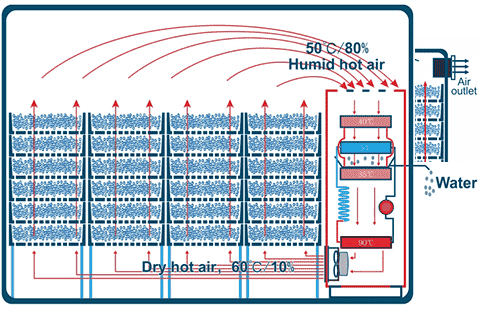

Drying essence is take moisture away, but takes away the moisture temperature is not the most critical factor. The key for drying is depending on relative humidity within certain space, Baixin Company took advantage of the dry essence, originality developed a "Closed Cycle" dryer, changed the traditional heat pump dryer "bake" to "dehumidifier”. Its several advantages were unmatched by the traditional heat pump dryer.Baixin Food Dehydrator has a compact structure, great energy-saving, wide application, high drying quality, easy operation, simple installation and removable. it is the best drying equipment for small firms, drying experiment and scientific research. The users only connect the power to use, is the easiest operation heat pump dryer.

Advantage of tomatoes dehydrator/drying machine

1:Applicable:Vegetable,fruit,meat,seafood,agricultural ,noodle,wooden2:Output:100-2000kg/h

3:Heat pump model: 1P/1.5P/3P/8P

4:Core advantages: Commercial All-in-one universal drying equipment without installation for any material

Tomatoes dehydrator video:

Previous post:

Next post:

RELATED PRODUCTS

Hot News

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

RELATED NEWS

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.