Bsf Larvae Drying Machine/Bsf Drying Machine

Bsf Larvae Drying Machine/Bsf Drying Machine

Back soldier fly is one of the designated resource insects of FAO (food and Agriculture Organization of the United Nations). It can feed on livestock manure and domestic garbage and produce high-value animal protein feed. Because of its rapid reproduction, high absorption and conversion rate, easy management, low feeding cost and other characteristics, it can be used as a resource. Its larvae are promoted all over the world.

Bsf has not only made great contributions in the field of environmental protection, but also dried bsf larvae can be used as a valuable protein resource for food and animal feed. Therefore, drying bsf larvae has bright prospects and huge market. If you want to start a bsf business, what drying machine is needed to dry bsf larvae? Next, I will share with you the machinery for drying bsf larvae.

Bsf Larvae Drying Machine

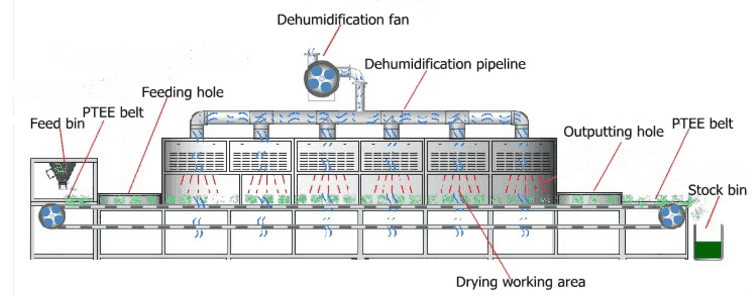

Generally, microwave dryers are used to dry black soldier flies. So why choose microwave dryers or what are the advantages of microwave dryers for drying black soldier flies? Next, I will share with you the advantages of bsf microwave dryer.

Advantages of bsf microwave dryer

1. The microwave dryer can achieve instant heat without preheating, so it takes less time than the traditional drying method, which makes the black soldier flies have a strong fragrance;

2. Fast drying speed, high drying quality, and sterilization while drying.

3. There will be no black spots after drying, and the insect body is full and easy to grind.

4. Dryness, high dewatering ability, easy to grind after drying.

5. Dry bsf evenly.

Therefore, compared with the conventional method, the bsf microwave dryer is more suitable for drying bsf larvae and is the most popular in the market. So how to use a microwave dryer? Next, I will introduce you how to use the microwave dryer and the drying principle?

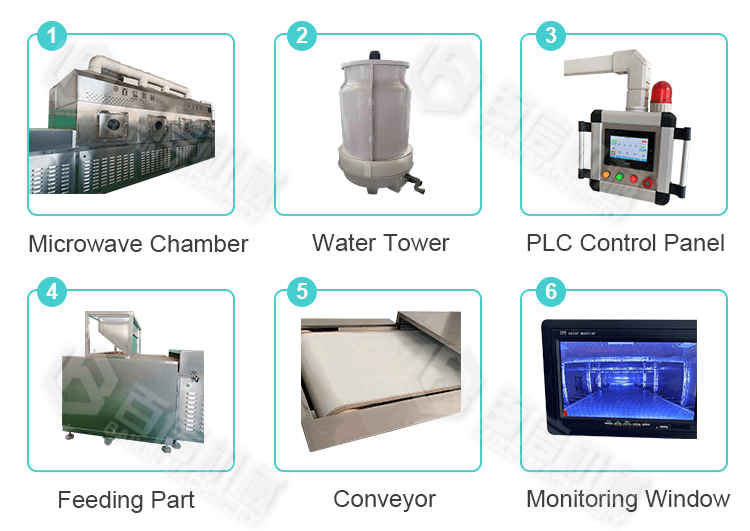

How to dry bsf larvae

Place the bsf larvae on the conveyor belt of the microwave dryer. The larvaes are dispersed on the conveyor belt through a homogenizing device on the conveyor belt. During the operation of the equipment, the microwave generator generates microwaves. The bsf larvaes enter the heating chamber through the conveyor belt. At this time, the water and bacteria in the materials evaporate under the action of microwave energy to achieve the purpose of sterilization and drying. The drying time is 5-10 minutes. The dried bsf larvaes are discharged from the discharge port.

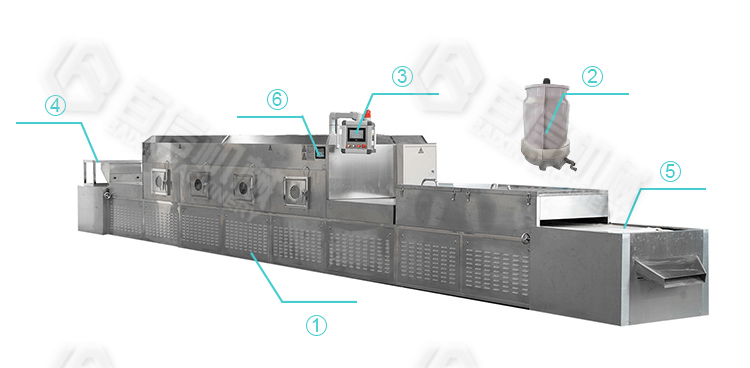

Components of black soldier fly microwave dryer

A complete black soldier fly microwave dryer includes: microwave chamber, water tower, PLC control panel, feeding part, conveyor, monitoring window.

Working principle of bsf microwave dryer

Microwaves are electromagnetic waves at a frequency of 300 MHz to 300 GHz.The material in the heating medium in the molecules of water is a polar molecule. It is the rapidly changing under high-frequency magnetic field, its polarity orientation will be with the change of external electric field changes, resulting in molecular motion and friction between the effect, this field of the microwave field can be transformed into thermal energy within the medium, the temperature of the bsf larvaes increased, heating and puffing a series of physical and chemical processes, to achieve the purpose of microwave heating and drying.During the equipment is working the microwave generator produces the microwave. The larvaes enter into the heating chamber by conveyor. At this time, moisture and bacteria inside the larvaes evaporate under the action of microwave energy to achieve unfreeze sterilization ripening fixing drying purpose.

Technical parameters of bsf larvaes microwave dryer

| Size | Power | Dewater | Cabinet | Feeding mesh width | Temperature | Controll |

| 6300mm*665mm*1800mm | 10KW | 10kg/h | 2 | 500mm | 0~400℃ | PLC |

| 6300mm*950mm*1800mm | 15KW | 15kg/h | 2 | 750mm | 0~400℃ | PLC |

| 8500mm*1200mm*1800mm | 20KW | 20kg/h | 4 | 500mm | 0~400℃ | PLC |

| 8500mm*1500mm*1800mm | 30KW | 30kg/h | 4 | 750mm | 0~400℃ | PLC |

| 10500mm*1500mm*1800mm | 40KW | 40kg/h | 6 | 750mm | 0~400℃ | PLC |

| 10500mm*2000mm*1800mm | 50KW | 50kg/h | 6 | 1200mm | 0~400℃ | PLC |

| 10500mm*2000mm*1800mm | 60KW | 60kg/h | 6 | 1200mm | 0~400℃ | PLC |

| 12500mm*2000mm*1800mm | 70KW | 70kg/h | 8 | 1200mm | 0~400℃ | PLC |

| 12500mm*2000mm*1800mm | 80KW | 80kg/h | 8 | 1200mm | 0~400℃ | PLC |

| 14500mm*2000mm*1800mm | 90KW | 90kg/h | 10 | 1200mm | 0~400℃ | PLC |

| 14500mm*2000mm*1800mm | 100KW | 100kg/h | 10 | 1200mm | 0~400℃ | PLC |

| 16500mm*2000mm*1800mm | 120KW | 120kg/h | 12 | 1200mm | 0~400℃ | PLC |

| 20000mm*2000mm*1800mm | 150KW | 150kg/h | 16 | 1200mm | 0~400℃ | PLC |

| 20000mm*2000mm*1800mm | 160KW | 160kg/h | 16 | 1200mm | 0~400℃ | PLC |

| 22000mm*2000mm*1800mm | 180KW | 180kg/h | 18 | 1200mm | 0~400℃ | PLC |

| 23400mm*2000mm*1800mm | 200KW | 200kg/h | 20 | 1200mm | 0~400℃ | PLC |

Do you want to start a bsf business? If you want to know more professional questions about black soldier fly larvae drying machine, please feel free to contact us online!

Bsf larvae drying video:

-

Hemp Drying Machine Delivery To France

Our French customers have been in the hemp business for many years and have their own plantations. We learned through the Internet that we are engaged in the manufacture of drying equipment and consulted with us on hemp drying. The customer requires that the drying output of hemp is 300kg/h, the heat source uses an air energy heat pump, the heat can be recovered, the installation should be simple, and one container is finished.

-

8 Sets Flowers Dryer Tested Well In Client's Site

This time, we have equipped 8sets flowers dryer of model BX-15m*2.2*4layers. Drying material: flowers Output: 120 tons/day Drying machine: continuous multi-layer mesh belt drying machine Drying time: 1-2 hours

-

Henan Baixin Export 6 Sets Leaf Dryer To American!

In recent days, we have continuously exported 6 dryers to the United States! Customer drying material: leaf material Drying temperature: strict drying temperature and humidity requirements. The drying temperature needs to be kept at about 30-50℃, and the temperature is moderate, which can well retain the effective ingredients, which is conducive to the later material extraction and reprocessing...

-

Coconut Dryer Machine Malayalam

If you want to dry coconuts, you need a professional coconut dryer machine. So what are the coconut dryer machines? How to choose the right dryer machines? Next, I will share with you three types of coconut dryer machines, coconut drying room, mesh belt coconut dryer machine and coconut dryer all-in-one machine. -

Garlic Drying Methods

After drying, the garlic not only retains the original taste and nutrition, but also is more convenient to store and carry. What kind of method can achieve such drying effect? Let's explore this issue together.

There are two ways to dry garlic. One is to do dry garlic at home, and the other is the large quantities of the garlic industry to produce dried garlic. -

Copra Drier

At present, copra drier can be divided into three types according to the output: Continuous Mesh Belt Copra Drier with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Drier with output of 100-1500kg/batch. In addition to different output, these three driers are also different in terms of heat source and working principle. Each has its own advantages, the following is a detailed introduction. -

Copra Dryer Price

Under normal circumstances, copra manufacturers dry the coconut before shipping it out. Today I will share with you the professional copra dryer by Baixin Machinery and the copra dryer price. At present, copra dryer can be divided into three types according to the output: Continuous Mesh Belt Copra Dryer with output of 300-2000kg/h; Heat Pump Copra Drying Room with output of 100-5000kg/batch; and All-in-one Copra Dryer with output of 100-1500kg/batch.